ABB IMDSI13 Digital Slave Input Module

Product type: I-O-Module, specifically Digital Slave Input Module, is positioned as a slave device for Symphony Plus control system, receiving external digital signals and transmitting them to the main control system.

Belonging to the product system: classified under ABB's "Products", "Control Systems", "Symphony Plus", "I/Os", HR Series (Harmony Rack) I/O ", which is the HR series (Harmony Rack) I/O module family under the Symphony Plus control system, suitable for rack mounted installation and system integration of this series

ABB IMDSI13 Digital Slave Input Module

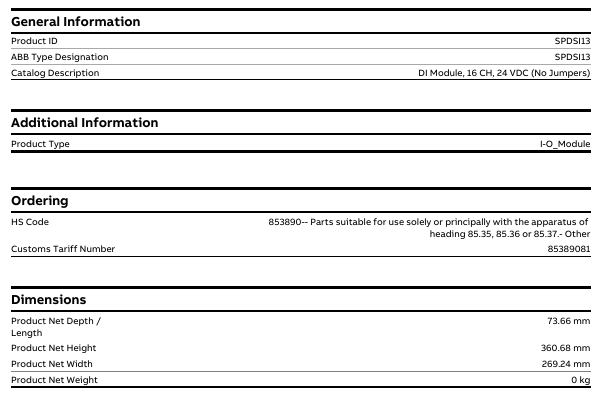

Product basic information

1. Core identification and classification

Product ID/Model: IMDSI13 (ABB official model identification), document associated link labeled "SPDSI13", speculated to be due to differences in series ownership or regional model labeling, core parameters are based on "IMDSI13".

Product type: I-O-Module, specifically Digital Slave Input Module, is positioned as a slave device for Symphony Plus control system, receiving external digital signals and transmitting them to the main control system.

Belonging to the product system: classified under ABB's "Products", "Control Systems", "Symphony Plus", "I/Os", HR Series (Harmony Rack) I/O ", which is the HR series (Harmony Rack) I/O module family under the Symphony Plus control system, suitable for rack mounted installation and system integration of this series.

2. Multi language support

The document page supports viewing in 16 languages (including Chinese, English, German, Japanese, Korean, etc.), making it convenient for users from different regions to access technical information. The corresponding version can be selected through the page language switching function.

Key physical and compliance parameters

1. Size and weight

Dimensions: The product has a net depth/length of 73.66mm, a net height of 360.68mm, and a net width of 269.24mm. It is compatible with the installation dimensions of the HR series (Harmony Rack) rack and requires confirmation of specific installation compatibility based on rack specifications.

Weight: The document indicates "0 kg", which is speculated to be a simplified net weight label without packaging or data is currently missing. The actual weight of industrial I/O modules is usually around a few hundred grams to 1 kilogram, and the final technical document from ABB should be used as the standard.

2. Environmental and Compliance Attributes

WEEE classification: Belongs to "5. Small Equipment (No External Dimension More Than 50 cm)", which means "small equipment (with no external dimensions exceeding 50 cm)" and meets the classification requirements of the EU Waste Electrical and Electronic Equipment Directive (WEEE). Disposal must comply with corresponding environmental standards.

Battery related: Excluding batteries (Number of Batteries: 0), there is no need to consider additional operations related to battery replacement and environmental recycling.

3. Import and export and tariff information

HS code: 853890 (specific sub target note: "853890- Parts suitable for use completely or primarily with the apparatus of heading 85.35, 85.36 or 85.37- Other"), which means "parts specifically or primarily used for equipment of heading 85.35, 85.36 or 85.37, other".

Customs tariff code: 85389081, used for tariff accounting and classification during import and export customs declaration. The specific tax rate needs to be confirmed in conjunction with the customs policies of the importing region.

Installation precautions

First, the importance of industrial equipment installation

In modern industrial production, various equipment and machines are widely used in various fields, such as manufacturing, energy industry, chemical industry and so on. The installation of industrial equipment is directly related to production efficiency and product quality. Proper installation and commissioning of good equipment can ensure the stable operation of the production line, improve production efficiency and product quality, reduce maintenance costs, and ensure the safety of employees.

Second, the steps of industrial equipment installation

1. Preparation: Before the installation of industrial equipment, it is necessary to carry out adequate preparation work. This includes the tools and equipment required for installation, cleaning and preparation of the installation site, and making installation plans and schedules.

2. Determine the installation position: Determine the installation position of the equipment according to the requirements of the equipment and the layout of the production line. When determining the location, the weight and size of the equipment need to be considered, as well as the coordination of the equipment with the surrounding environment.

3. Install the device: Assemble and install the device according to the installation instructions. Ensure that the device is securely and accurately connected, while protecting the appearance and internal components of the device.

4. Connect power supplies and pipelines: For devices that require power supplies and power supplies, properly connect power supplies and pipelines. The connection of power supply and pipeline should comply with safety standards to avoid hazards such as electric shock and leakage.

5. Commissioning the device: After the installation is complete, you need to commission the device to ensure that the device can run properly. It includes checking the functions and performance of the equipment, adjusting the parameters and Settings of the equipment, and carrying out the necessary tests and inspections.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands