AB Allen Bradley 1492 series terminal block

Pages 24-41 of IEC Spring Clamp Type Terminal Blocks introduce terminal blocks with different installation methods such as mini installation and surface installation, emphasizing features such as fast wiring, maintenance free, and electrical performance parameters

Pages 42-64 of IEC Terminal Block Accessories cover installation rails, end shields, partitions, jumpers, plugs, and other accessories, indicating their applicable terminal block types, sizes, packaging quantities, and functions

NEMA Terminal Blocks pages 65-68 include tubular screw type, panel mounted, and other terminal blocks, specifying voltage and current levels, wire range, and insulation temperature range

NEMA Terminal Block Accessories pages 69-77 cover installation rails, stacking bridges, end anchors, marking systems, etc. Provide accessory specifications and compatibility information with the terminal block

Power Blocks pages 78-90 include open mini power terminal blocks, high fault short-circuit current rated terminal blocks, etc., with a focus on current capacity, wire connection methods, and short-circuit current tolerance

The additional resources section provides relevant reference documents (such as the "Industrial Automation Wiring and Grounding Guide") and product certification query websites to help users obtain more installation specifications and certification details; At the same time, explain the ways to view, download, and order paper versions of technical documents.

AB Allen Bradley 1492 series terminal block

Overall Structure and Core Blocks

Main content of page numbers corresponding to core sections

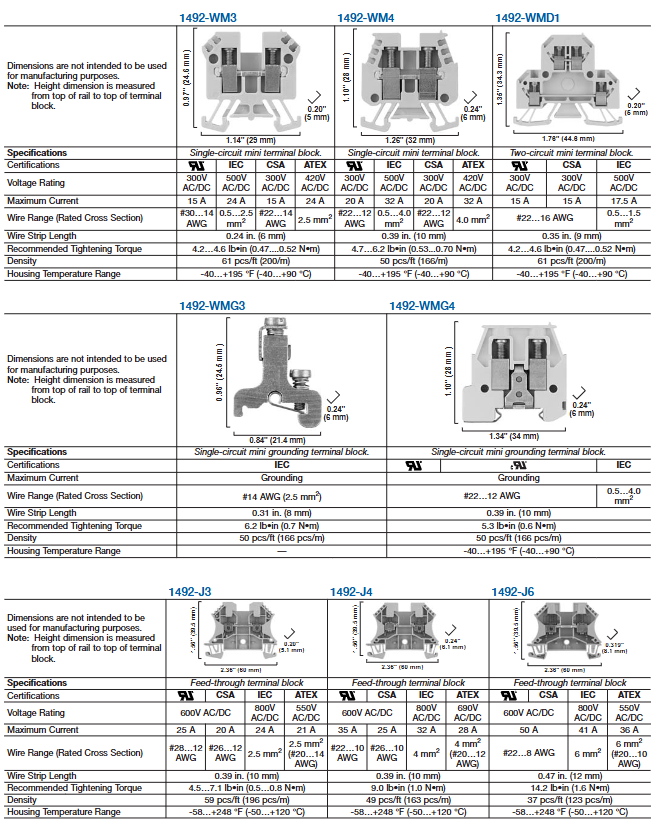

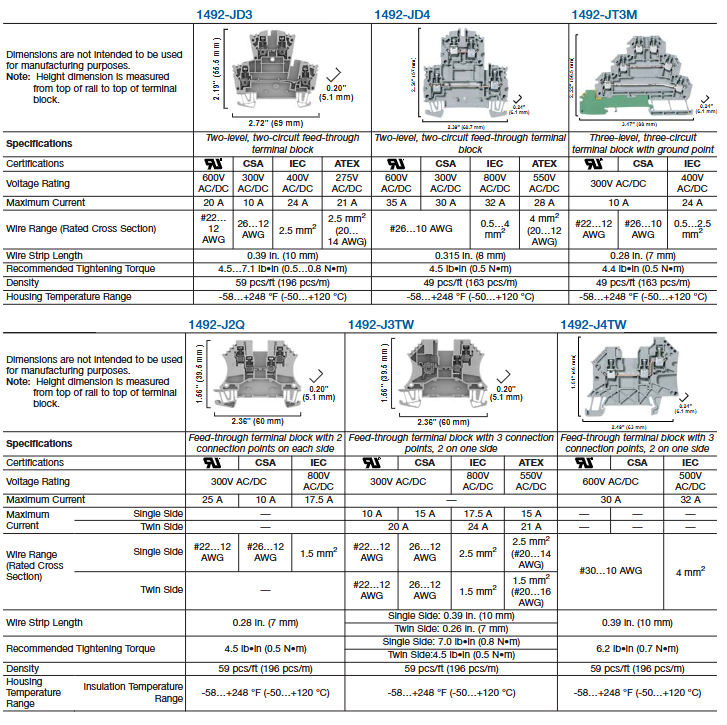

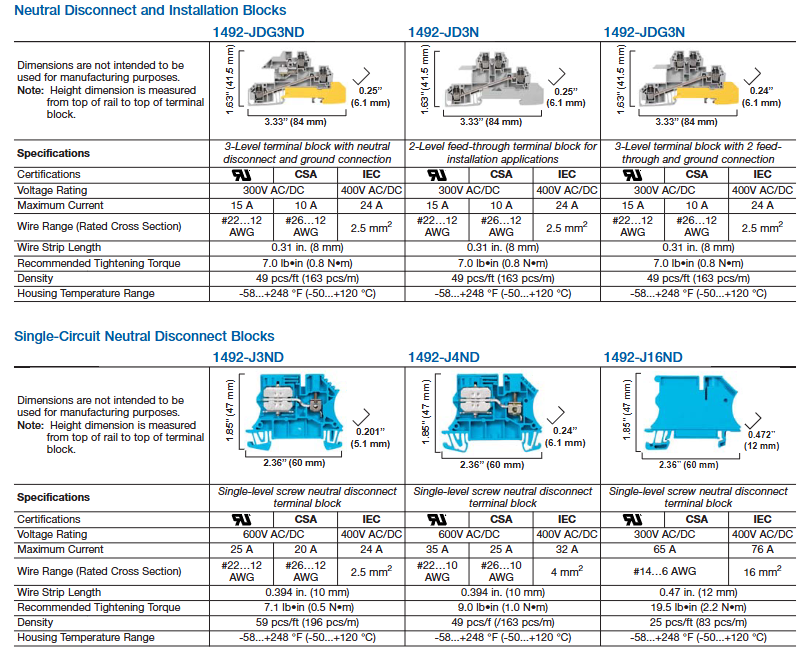

The IEC Screw Type Terminal Blocks on pages 3-23 include various types such as single circuit mini terminal blocks, grounding terminal blocks, threading terminal blocks, etc., detailing parameters such as size, certification, voltage and current ratings, and wire range

Pages 24-41 of IEC Spring Clamp Type Terminal Blocks introduce terminal blocks with different installation methods such as mini installation and surface installation, emphasizing features such as fast wiring, maintenance free, and electrical performance parameters

Pages 42-64 of IEC Terminal Block Accessories cover installation rails, end shields, partitions, jumpers, plugs, and other accessories, indicating their applicable terminal block types, sizes, packaging quantities, and functions

NEMA Terminal Blocks pages 65-68 include tubular screw type, panel mounted, and other terminal blocks, specifying voltage and current levels, wire range, and insulation temperature range

NEMA Terminal Block Accessories pages 69-77 cover installation rails, stacking bridges, end anchors, marking systems, etc. Provide accessory specifications and compatibility information with the terminal block

Power Blocks pages 78-90 include open mini power terminal blocks, high fault short-circuit current rated terminal blocks, etc., with a focus on current capacity, wire connection methods, and short-circuit current tolerance

The additional resources section provides relevant reference documents (such as the "Industrial Automation Wiring and Grounding Guide") and product certification query websites to help users obtain more installation specifications and certification details; At the same time, explain the ways to view, download, and order paper versions of technical documents.

Core technical parameters and characteristics of various terminal blocks

(1) IEC screw type terminal block

Basic commonality

Certification system: It generally complies with international certification standards such as IEC, CSA, ATEX, and some models meet UL standards to ensure applicability in different regions and industries.

Temperature range: Most terminal blocks operate at -58...+248 ° F (-50...+120 ° C), while some mini terminal blocks operate at -40...+195 ° F (-40...+90 ° C), suitable for complex industrial temperature environments.

Wire Connection: Supports wires of different specifications (AWG or mm ²), specifying the wire stripping length (such as 0.39in, 0.47in, etc.) and recommended tightening torque (such as 4.5... 7.1lb · in) to ensure connection reliability.

Typical Model Example

1492-J series threading terminal block: 1492-J3 voltage rated 600V AC/DC, maximum current 25A, wire range # 28... 12AWG; 1492-J120 voltage 1000V AC/DC, maximum current 269A, wire range # 4... 4/0AWG, covering application scenarios from low current small wires to high current large wires.

1492-W series single circuit terminal block: 1492-W3 voltage 600V AC/DC, maximum current 20A, wire range # 30... 14AWG, suitable for small control circuits; 1492-W16S voltage 600V AC/DC, maximum current 85A, wire range # 14... 4AWG, meets medium to high current requirements.

Grounding terminal block (such as 1492-JG series): 1492-JG3 is only used for grounding, with wire range # 30... 12AWG. 1492-JG120 is used for grounding, with wire range # 4... 4/0AWG, to ensure circuit grounding safety.

(2) IEC spring clip type terminal block

Core strengths

Installation efficiency: wiring time is reduced by more than 50%, and only a flathead screwdriver is needed for installation, without the need for subsequent re tightening, reducing maintenance costs.

Reliability: Using tin plated terminals and stainless steel spring clips, corrosion-resistant and vibration resistant, ensuring long-term stable contact; Top wire connection design for easy operation.

Safety design: Most models support 2mm standard test probes or stacked test plugs, with insulation blocks to prevent the insulation layer from entering the conductive area when connecting small-sized wires.

Key parameters and models

Voltage and current: 1492-L3 voltage 600V AC/DC, maximum current 24A; 1492-L120 voltage 1000V AC/DC, maximum current 228A, suitable for different power requirements.

Special function model: 1492-LD4DF diode terminal block, rated reverse voltage of 600V, average rectified forward current of 1.0A, used for circuit orientation and suppression; 1492-LD4SS surge suppression terminal block, nominal operating voltage 120V, peak current 1200A, protects relays, contactors and other components from transient impacts.

(3) NEMA terminal block

Main types and specifications

Tubular screw type: such as 1492-CA1, voltage 600V AC/DC, maximum current 55A, wire range # 22... 8AWG, with pressure plate design to enhance wire fixation effect.

Panel installation type: 1492-HC6 is a high-density panel installation terminal block with a maximum current of 25A per pole and a wire range of # 30... 12AWG, saving panel space and suitable for dense wiring scenarios.

High temperature type: 1492-15T and 1492-25T work at temperatures up to -40...+300 ° F (-40...+149 ° C), suitable for high-temperature industrial environments (such as metallurgy and chemical industry), with a voltage of 600V AC/DC and currents of 35A and 45A, respectively.

Short circuit current rating (SCCR): 1492-CAM1 has an SCCR of 100000A at 600V, and 1492-CE2 also has an SCCR of 100000A at 600V to ensure equipment safety in the event of a short circuit fault.

(4) Power Blocks

Application positioning: Used in high-power distribution scenarios, such as industrial equipment power distribution, large motor control, etc., supporting large cross-section wires (such as 250kcmil, 600kcmil) and high current (such as 760A).

key performance

Short circuit current tolerance: Most models have a high fault SCCR of 100000A (such as 1492-BE, 1492-BF), and some models have an SCCR of 35000A when used in conjunction with circuit breakers. The selection of overcurrent protection devices should be based on the type to ensure that the system is not damaged in the event of a fault.

Wire connection: 1492-PD3163 supports 400kcmil... 3/0Cu wires (input end) and 2-8AWG wires (output end), allowing multiple small wires to be connected to meet power distribution requirements; Some models distinguish between copper (marked with "C") and aluminum terminals, and are compatible with wires of different materials.

Safety and maintenance: Provide protective covers (such as the 1492-PBC series) and marking strips to facilitate circuit identification and prevent accidental contact; Clear size parameters facilitate installation layout planning.

Terminal block accessory system

(1) IEC terminal block accessories

Installation and fixing category

Installation guide rail: such as 199-DR1 (35mm × 7.5mm × 1m), 1492-N1 (breakable 3ft guide rail), used to fix the terminal block, reduce the use of panel screws, and facilitate the disassembly and adjustment of the terminal block.

End anchor and end baffle: 1492-EAJ35 end anchor enhances the rigidity of the terminal block group to prevent sliding along the guide rail; The 1492-EBL series end shields (such as 1492-EBL3) provide insulation protection and are compatible with terminal blocks of different heights.

Circuit connection and isolation class

Jumper: divided into screw type (such as 1492-CJJ series) and non screw type (such as 1492-CJL series), supports 2-50 pole configuration, can be cut, and carries 100% rated current of the terminal block. Attention should be paid to the derating (such as 400V) and partition requirements when crossing different potentials.

Partitions and separators: The 1492-PPJD3 partition is used for visual and electrical isolation of terminal groups, while the 1492-SP3 partition isolates adjacent jumpers to ensure circuit safety.

Testing and Identification Category

Test plugins: 1492-TP23 test plug, 1492-TPS23 test socket, convenient for circuit testing; 1492-TA285 test adapter, suitable for different testing scenarios.

Marking system: ClearMark printer (600/1200dpi, supports color printing) and X-Y plotter meet different batch marking requirements; Blank markings (such as 1492-M3X12), pre printed markings (by serial number), and custom markings can be designed and ordered through software to ensure clear circuit identification.

(2) NEMA terminal block accessories

Stacking Bridge: Composed of 1492-N26 (external mounting pins), 1492-N27 (side panel extensions), etc., it can stack up to 4 layers of terminal blocks, saving panel space. Only fuse blocks, circuit breakers, etc. are allowed to be installed on the top layer.

Marking and tools: 1492-N43 label paper (132 pieces/sheet), 1492-N8 engravable marking strip, used for terminal identification; 1492-N90 screwdriver (3mm hardened blade), 1492-KWC wire breaking tool, convenient for installation and operation.

Selection and application precautions

Standard adaptation: Select certified terminal blocks based on the application region (such as NEMA for North America and IEC for Europe) and industry standards (such as ATEX for explosion-proof environments) to avoid compliance risks.

Electrical parameter matching: Based on the circuit voltage, current, and wire specifications, select the terminal block according to its rated value. For example, choose the 1492-J120 and 1492-PD series for high voltage and high current scenarios, and choose 1492-W3 and 1492-L3 for low current control circuits.

Environmental adaptation: 1492-15T and 1492-25T are preferred for high-temperature environments; Choose spring clip type terminal block (1492-L series) for vibration environment to ensure stability.

Safety and maintenance: Reasonably select accessories (such as end shields, testing plugins, marking systems) for easy maintenance and troubleshooting in the later stage; Follow the requirements of tightening torque, wire stripping length, etc. to avoid faults caused by poor connections.

Short circuit current consideration: Based on the type and rated value of overcurrent protection devices (fuses, circuit breakers), confirm the SCCR of the terminal block to ensure safety in case of system failure, and refer to the SCCR table in the document for selection.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands