The enlightenment of the development of metallurgical technology in ancient China to modern industry from the perspective of "Nature works open things"

The development of metallurgical technology in ancient China has important implications for modern industry. From the historical background and cultural context, this paper is divided into six chapters to deeply discuss the development of ancient metallurgical technology in China and its enlightenment to modern industry. The first chapter introduces the origin and development of ancient metallurgical technology in China.

The second chapter discusses the role of ancient Chinese metallurgical technology in the Silk Road trade. The third chapter analyzes the contribution of ancient metallurgical technology to the fields of architecture, weapons, tools and works of art.

The fourth chapter introduces the inheritance and development of ancient metallurgical technology in China. The fifth chapter describes the enlightenment of ancient metallurgical technology to modern industry, such as improving the technical level, paying attention to environmental protection and energy saving. Finally, Chapter six summarizes the full text.

The origin and development of ancient metallurgical technology in our country

Ancient metallurgical technology is an important part of ancient science and technology civilization in China, and its origin can be traced back to the late Neolithic Age. According to archaeological research, the earliest copper products in China can be traced back to about 2800 BC, while the appearance of iron is much later, about 600 BC.

In ancient times, the development of metallurgical technology was closely related to the social and economic development of the time. In ancient China, the development of metallurgical technology went through different stages such as the Bronze Age, the Bronze Age and the Iron Age.

In the Bronze Age, people mainly used copper to make various daily articles and ritual vessels, such as POTS, bowls, plates, 匜, statues, tripod and so on. Smelting technology in the Bronze Age was dominated by furnaces built inside mud walls that burned copper ore with charcoal to extract copper.

In this period, the smelting technology gradually improved and optimized to the furnace type, furnace temperature, smelting time, smelting formula, etc., so that the quality and quantity of copper ware continued to improve.

With the development of society, bronze ware gradually replaced bronze ware as the main production tools and ritual objects. Smelting technology was further developed in the Bronze Age, mainly using blast smelting furnaces, which can produce high temperatures and strong reducing atmospheres, making smelting efficiency greatly improved.

At the same time, people began to use alloys to make bronzes, melting copper and tin, lead and other metals together in a certain proportion, so that the performance and quality of bronzes have been greatly improved.

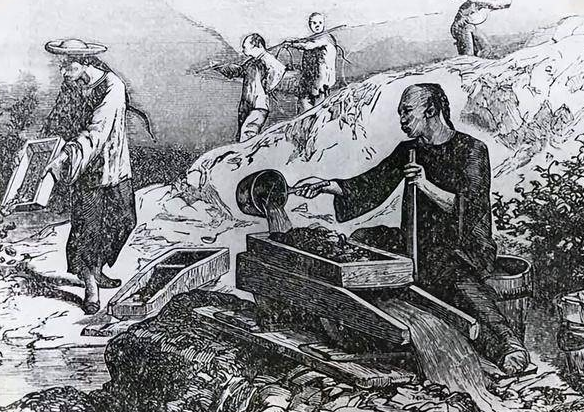

The arrival of the Iron Age marked an important milestone in ancient metallurgical technology in China. During this period, people began to widely use iron products, such as farm tools, weapons, vehicles and so on.

Smelting technology in the Iron Age mainly used blast furnace smelting, which used coke as a reducing agent to extract iron. This smelting method can obtain high temperature and high efficiency, so that the output and quality of iron have been greatly improved.

At the same time, people also began to use iron alloy to make steel products, such as swords, needle clusters, etc., so that the performance and quality of steel products have been greatly improved.

In addition to copper and iron, other metals such as gold, silver, tin and lead were widely used in ancient China. The smelting technology of these metals has also been widely used in ancient times, among which the smelting technology of gold and silver is the most complex and fine, requiring multiple processes and high temperature smelting to obtain pure metals.

The role of China's ancient metallurgical technology in the Silk Road trade

The Silk Road was an important channel for trade and cultural exchanges between China and Central Asia and Eurasia in ancient times. The development and application of China's ancient metallurgical technology played an important role in the Silk Road trade.

First of all, the development of ancient metallurgical technology in China has greatly improved the production of silk. In the production process of silk, iron spinning wheels, scissors, needles and other tools need to be used, and the quality and quantity of these tools are closely related to the development of smelting technology.

At the same time, the dyeing and printing of silk also required the use of copper dye tanks and printing utensils, and the manufacture of these utensils also required advanced smelting technology. Therefore, the development of ancient metallurgical technology in China made the production and processing of silk more efficient and fine, and promoted the circulation and dissemination of silk in the Silk Road trade.

Secondly, the application of ancient metallurgical technology in China also improved the production and processing of other commodities in the Silk Road trade. In the Silk Road trade, iron farm tools, weapons, utensils, etc., were very important commodities. The improvement of the quality and performance of these commodities also benefited from the development of ancient metallurgical technology in China.

For example, with the continuous improvement of the manufacturing technology of iron weapons, iron swords and iron guns became one of the important commodities in the trade on the Silk Road. At the same time, copper vessels and bronzes were also widely circulated in the Silk Road trade, becoming an important carrier for the life and cultural exchanges of residents in Central Asia and Eurasia.

In addition, the development of China's ancient metallurgical technology also promoted cultural exchanges in the Silk Road trade. China's ancient bronze mirrors, bronze tripod and other works of art have also been widely spread and appreciated in Central Asia and Eurasia. At the same time, iron-cast Buddha statues and clocks also became important cultural products in the Silk Road trade.

China's ancient metallurgical technology for construction, weapons, tools and works of art and other fields

The development and application of ancient metallurgical technology in China not only has a profound impact on the metallurgical industry, but also is widely used in the fields of construction, weapons, tools and works of art. Its specific application will be described in detail below.

Architectural field

In ancient Chinese architecture, copper, iron and other metal materials are often used in the manufacture of building components. For example, ornaments such as copper door rings, bronze lions, and iron chains are often used in buildings.

At the same time, China's ancient building tools such as hammer, iron pliers, iron ax, etc., also need advanced smelting technology, the use of these tools in the building can improve the quality and efficiency of the building. In addition, China's ancient city walls, gates and other defense facilities also need advanced smelting technology to ensure their robustness and durability.

Weapons field

The progress of smelting technology in ancient China has also had a huge impact on the manufacture of weapons. With the advent of iron, the original bronze ware was gradually replaced. The appearance of iron sword, iron lance, iron bow and other weapons made the ancient Chinese weapon manufacturing reach a new height.

Among them, the appearance of the iron sword is to promote the progress of weapon manufacturing, because the iron sword is not only sharper, but also the service life is longer than the bronze sword. At the same time, the manufacture of gunpowder in ancient China also needs advanced smelting technology. With the application of gunpowder, firearms have gradually become an important part of ancient Chinese military power.

Tool domain

China's ancient tools also need advanced smelting technology to manufacture. For example, the appearance of tools such as hammer, iron axe and iron saw greatly improved the production efficiency in ancient China. In addition, China's ancient agricultural tools such as iron Lei, iron plow, etc., also benefited from the progress of smelting technology, its quality and service life have been improved.

Art field

Among the ancient works of art in China, bronze ware and bronze ware need advanced smelting technology to manufacture. China's ancient bronze ware enjoys a high reputation in the world, among which the bronze ware of the Shang Dynasty is known as the peak of China's ancient bronze culture.

At the same time, China's ancient bronze mirror, copper furnace, copper tripod and other works of art also show the excellent level of ancient China's smelting technology. These works of art not only have practical value, but also artistic value, becoming the treasures of ancient Chinese culture.

Heritage and development of metallurgical technology in ancient China

The inheritance and development of ancient metallurgical technology in our country is a long and continuous historical process. In terms of inheritance, China's ancient smelting technology was carried out by the way of the ancestral master to the apprentice, and its inheritance has continued to modern times.

In the Ming and Qing Dynasties, the ancient smelting technology began to be passed on by specialized technical groups. These craft groups are usually composed of senior smelters who teach apprentices to pass on their skills and constantly develop and perfect them.

In terms of development, China's ancient smelting technology has been gradually improved in continuous practice. For example, in the Han Dynasty, the emergence of high-temperature iron-making technology injected new vitality into the development of smelting technology in ancient China.

By the Tang Dynasty, China's smelting technology had developed by leaps and bounds. The iron smelting technology of the Tang Dynasty not only has high technical content, but also has very high production efficiency, which makes the Tang Dynasty become one of the golden periods of ancient smelting technology in China.

By the Song Dynasty, China's ancient smelting technology has entered a new stage of development. The smelting technology of Song Dynasty has been improved and improved comprehensively, especially in the smelting of iron and steel has made remarkable achievements.

The blast furnace smelting technology in Song Dynasty had high technical content and production efficiency, which greatly increased the output of iron and steel, and also promoted the development of ancient smelting technology in China.

With the change of times, China's ancient smelting technology is also constantly developing and improving. In the Ming and Qing Dynasties, China's casting technology gradually matured, and the quality and efficiency of casting were improved.

The development and improvement of these technologies laid a solid foundation for the rise of modern industry in our country, and became the source and reference of modern industrial technology.

The enlightenment of China's ancient metallurgical technology to modern industry

Metallurgy technology in ancient China is an important component of Chinese culture and an important embodiment of ancient civilization. These ancient metallurgical techniques have important enlightenment and reference for modern industry.

First of all, China's ancient metallurgical technology emphasizes practice and technological innovation. The development of smelting technology in ancient China was realized through continuous practice and innovation, which provided useful reference for the development of modern industrial technology.

The development of modern industry also needs constant practice and technological innovation, only by constantly exploring new technical directions and methods, in order to occupy an advantage in the fierce market competition.

Secondly, China's ancient metallurgical technology pays attention to environmental protection and resource conservation. China's ancient smelting technology pays attention to the recycling of slag, makes full use of resources, and reduces the pollution to the environment. Modern industry in the development of environmental pollution and waste of resources and other problems, so learn from China's ancient metallurgical technology to save resources and environmental protection concept, is very necessary.

In addition, China's ancient metallurgical technology emphasizes personnel training and technical inheritance. The inheritance of ancient smelting technology in China is realized through the transmission of master and apprentice and the transmission of skill groups, which can not only inherit skills, but more importantly, train batches of high-quality technical talents.

Modern industrial development also needs a large number of technical personnel, so we can learn from China's ancient inheritance mode, pay attention to personnel training and technical inheritance, and provide a solid talent base for modern industrial

development.

Finally, China's ancient metallurgical technology emphasizes teamwork and sharing results. China's ancient smelting technology is usually completed by a group of technicians, these technicians cooperate with each other and share the results.

The development of modern industrial technology also requires the cooperation of many people to jointly complete technological innovation and product development, so we can learn from China's ancient smelting technology to emphasize the concept of team cooperation and sharing results, and promote the development of modern industrial technology.

Sum up

In this paper, the origin and development of ancient Chinese metallurgical technology, its role in the Silk Road trade, its contribution, inheritance and development in the fields of architecture, weapons, tools and works of art, and its enlightenment to modern industry are deeply discussed.

It can be seen that China's ancient metallurgical technology has an important position and role in all aspects, is an important part of China's ancient civilization, but also provides valuable experience and enlightenment for the development of modern industry.

Through the exploration of China's ancient metallurgical technology, we can find that China's ancient metallurgical technology can develop to such a high level, in addition to practice and experience accumulation, but also has a close relationship with the social background, cultural traditions and scientific concepts at that time.

The emphasis on practice and experience in the ancient culture of our country, advocating the concept of "harmony between heaven and man", all these have provided the important cultural foundation and ideological support for the development of ancient metallurgical technology in our country. At the same time, the development of ancient metallurgical technology in our country has also provided an important support and promoting role for the social and economic development at that time.

The author believes that: in general, the development of China's ancient metallurgical technology is a process full of innovation and exploration, and constantly explore and improve technology to meet the social and economic needs of the time.

At the same time, the inheritance and development of China's ancient metallurgical technology also provides important experience and enlightenment for the development of modern industry. In the future development, we should inherit and carry forward the fine tradition of China's ancient metallurgical technology, constantly innovate and explore to meet the needs of modern industry, and promote China's metallurgical industry to a higher level.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands