Bently 2300 series vibration monitor

Real time monitoring of vibration and speed, providing high vibration level alarms.

Supports multiple sensor inputs (accelerometer, velocity sensor, proximity sensor, etc.), with flexible signal processing and diagnostic capabilities.

Bently 2300 series vibration monitor

Product Overview

Core functions and application scenarios

The 2300 series vibration monitors (2300/20 and 2300/25) are cost-effective continuous vibration monitoring and protection equipment designed specifically for medium to low critical machinery, suitable for industries such as oil and gas, power generation, water treatment, papermaking, manufacturing, and mining. Its main functions include:

Real time monitoring of vibration and speed, providing high vibration level alarms.

Supports multiple sensor inputs (accelerometer, velocity sensor, proximity sensor, etc.), with flexible signal processing and diagnostic capabilities.

Model difference

2300/20: Equipped with 2 configurable 4-20 mA outputs, compatible with DCS systems, suitable for scenarios requiring data integration.

2300/25: Supports System 1 Classic connection and Trendmaster SPA interface, can utilize existing DSM SPA infrastructure, suitable for scenarios requiring trend analysis.

Technical specifications

1. Input parameters

Vibration input channel: 2 channels, supporting acceleration, velocity, and radial vibration measurement, with specific parameters as follows:

Accelerometer (ICP): bandwidth 0.2 Hz-20 kHz, range 2-80 g peak, sensitivity 5-1000 mV/g.

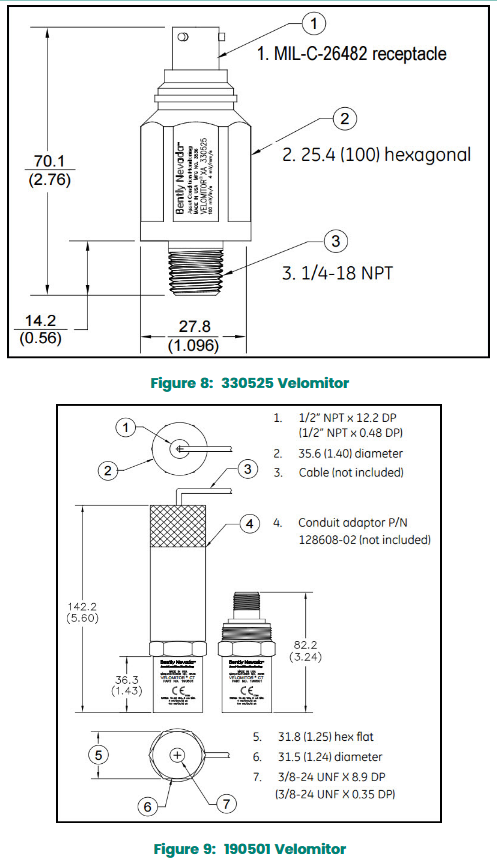

Speed sensor: bandwidth 0.2 Hz-20 kHz, range 0-50 in/s peak, sensitivity 5-1000 mV/in/s.

Radial vibration (proximity sensor): bandwidth 0.2 Hz-20 kHz, range 0-160 mil peak to peak, sensitivity 5-1000 mV/mil.

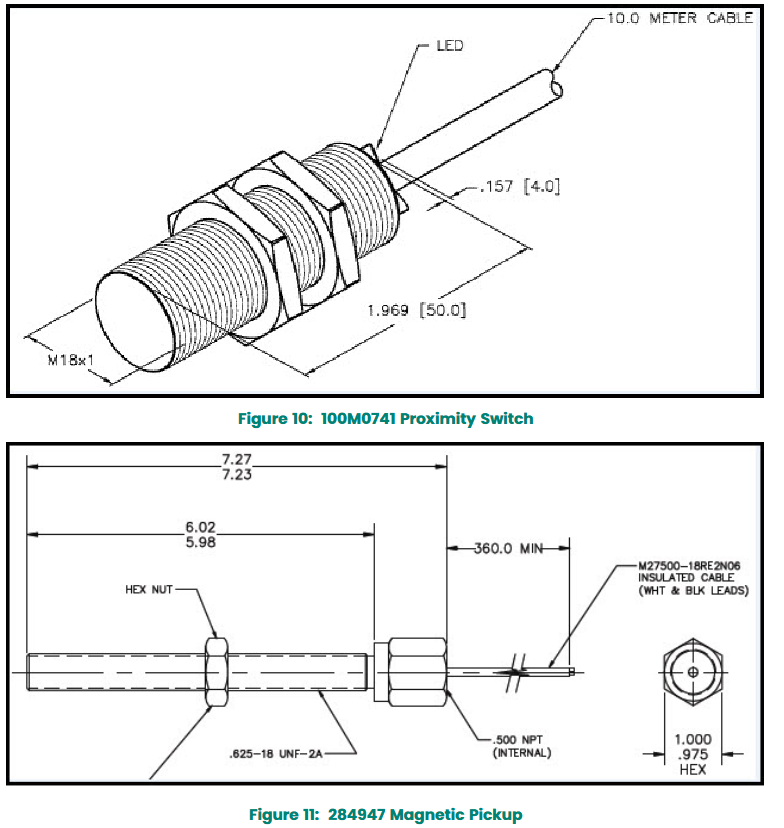

Speed/Keyphase Channel: 1 channel, supporting proximity probes, magneto electric pickups, and proximity switches, with a speed range of 1-120000 RPM for proximity probes and 200-120000 RPM for magneto electric pickups.

Process variable channel: supports temperature and other parameter monitoring, with an input voltage range of -0.25 to -22 V and an accuracy of ± 1% of full scale.

2. Output parameters

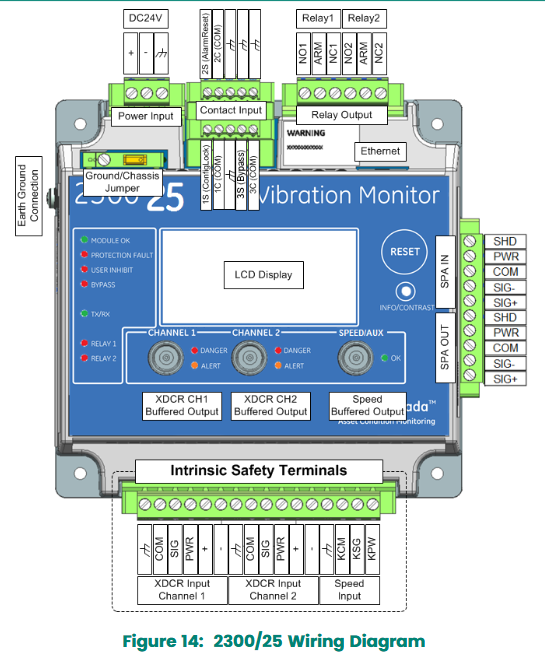

Buffer output: 3 channels (2 vibration+1 speed), with short circuit and EMI protection through BNC interface.

Relay output: 2-channel dry contacts, single pole double throw (SPDT), epoxy resin sealed, maximum switching voltage of 250 VAC/VDC, maximum current of 6 A (AC)/4 A (DC).

4-20 mA output (only 2300/20): 2 channels, internal power supply, load resistance 0-600 Ω, accuracy ± 1%, update rate of 100 ms.

SPA output (only 2300/25): Supports high-frequency signal transmission, with a frequency response of 10 Hz-3000 Hz ± 5% and an accuracy of ± 1% of full scale.

3. Communication and Display

Communication interface: 10/100 Base-T Ethernet, supporting Modbus protocol, configuring software to communicate through RSA encryption.

Display and indicator lights: The LCD screen displays real-time measurement values, set points, and configuration information; The LED indicator lights include operating status (OK), protection fault, alert/ranger, etc.

Environmental and physical parameters

Work environment:

Temperature: -30 ° C to+65 ° C (working), -40 ° C to+85 ° C (storage).

Humidity: 95% non condensing.

Vibration tolerance: 3 g.

Physical characteristics:

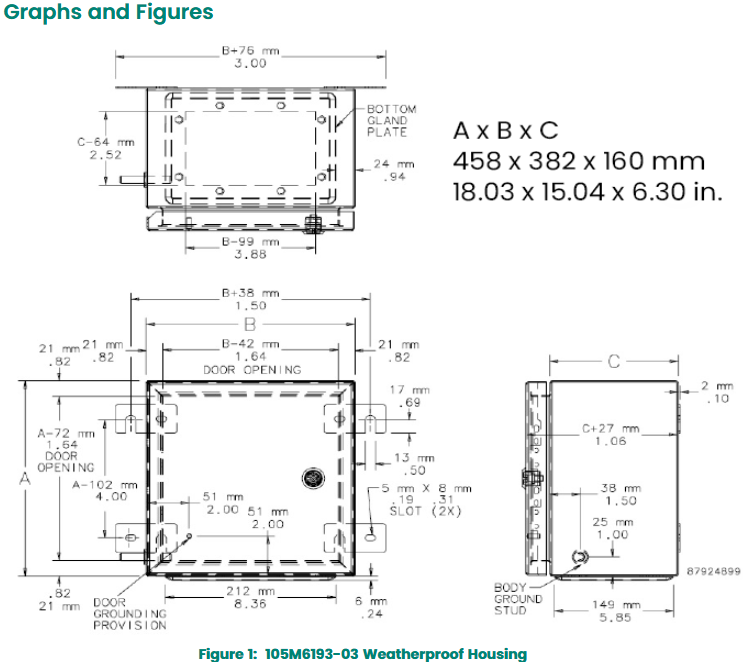

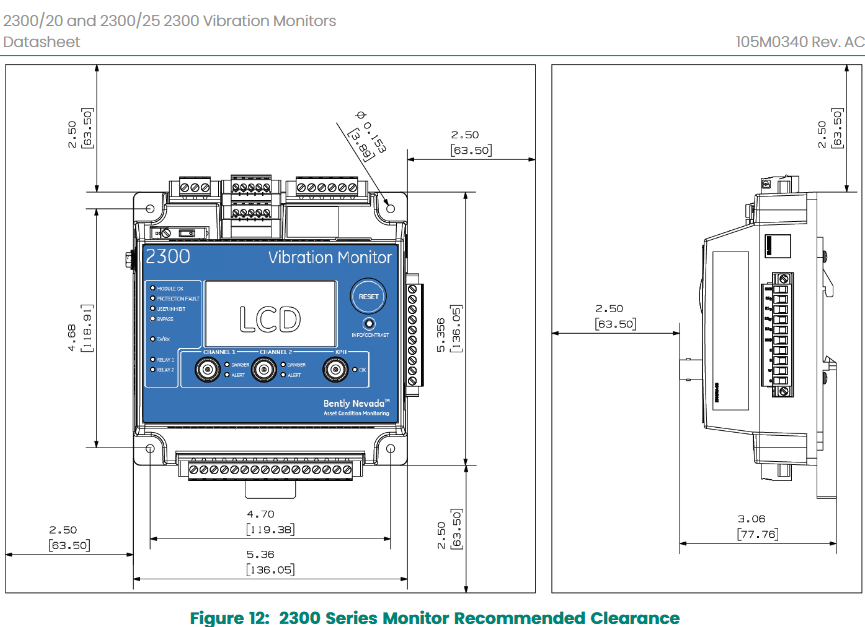

Dimensions: 127 mm x 127 mm x 76.2 mm (width x depth x height).

Weight: 1.03 kg (2.26 lbs).

Installation method: panel installation or DIN rail installation (including adapter).

Compliance and Certification Summary

1、 Basic compliance certification

FCC certification

The device complies with Part 15 of FCC regulations and must meet two conditions for operation:

Shall not cause harmful interference;

We must accept any interference received, including interference that may cause unexpected operations.

Electromagnetic Compatibility (EMC)

Compliant with EMC Directive 2014/30/EU;

Following standards:

EN 61000-6-2:2005 (Immunity to industrial environments);

EN 61000-6-4:2007+A1 (Emission limits for industrial environments);

EN 61326-1:2013 (Electromagnetic compatibility of measurement, control and laboratory equipment);

EN 61326-2-3:2013 (Electromagnetic compatibility requirements for specific equipment).

Electrical safety

Compliant with the Low Voltage Directive (LV Directive) 2014/35/EU;

Follow the standard EN 61010-1:2010 (Safety requirements for electrical equipment for measurement, control, and laboratory use).

RoHS Directive

Compliant with RoHS Directive 2011/65/EU, restricting the use of specific hazardous substances (such as lead, mercury, etc.) in electronic and electrical equipment to meet environmental requirements.

EPR label for Indian batteries

Certified by GE Oil&Gas India Private Limited, EPR certificate number: 1.1595372902047E+20, in compliance with relevant regulations on electronic waste management in India.

Hazardous Area Certification

1. ATEX certification

Compliant with ATEX Directive 2014/34/EU, following the standard:

EN 60079-0:2012/A1:2013 (General requirements for explosive atmospheres);

EN 60079-11:2012 (Intrinsically Safe Equipment);

EN 60079-15:2010 (non intrusive devices);

EN 60079-7:2015 (Increased Safety Equipment).

Specific certification level:

2300/20:II 3 G Ex na nC [ic] IIC T4 Gc; Ex ec nC [ic] IIC T4 Gc, The ambient temperature range is -30 ° C to+65 ° C.

2300/25:II 3 G Ex na nC ic [ic] IIC T4 Gc; Ex ec nC ic [ic] IIC T4 Gc, The ambient temperature range is -30 ° C to+65 ° C.

2. IECEx certification

Consistent with ATEX certification level, suitable for international explosive environment scenarios, certification mark is:

2300/20:Ex na nC [ic] IIC T4 Gc; Ex ec nC [ic] IIC T4 Gc。

2300/25:Ex na nC ic [ic] IIC T4 Gc; Ex ec nC ic [ic] IIC T4 Gc。

3. cNRTLus certification

Suitable for hazardous areas in North America, specific level:

Class I, Division 2/Zone 2:AEx nA nC [ic] IIC T4 Gc, Suitable for explosive gas environments in Group A, B, C, and D, with ambient temperatures ranging from -30 ° C to+65 ° C.

Certification precautions

Environmental temperature limit

When used in hazardous areas, the ambient temperature must be strictly controlled between * * -30 ° C and+65 ° C * *, as exceeding this range may result in certification failure.

INSTALLATION REQUIREMENTS

Installation must follow the wiring and grounding specifications specified in the equipment manual, especially in hazardous areas where cables (type A or B) that comply with EN 60079-25 standards must be used to ensure electrical connections meet explosion-proof requirements.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands