History of sewage treatment and environmental protection

Our government has always attached importance to environmental governance work, beloved Premier Zhou Enlai has put forward the "comprehensive planning, reasonable layout, comprehensive utilization, harm to benefit, relying on the masses, we do, protect the environment, benefit the people" 32 words policy, successive governments put forward the requirements of the governance of the Haihe River, three rivers and three lakes. Due to the high attention of the government from all walks of life, our country's sewage treatment cause has made great progress, but we should be keenly aware that the pace of development of industrial and agricultural production is rapid, especially the birth of the 20-year township enterprises in reform and opening up has changed the structure of our enterprises, some enterprises ignore social and environmental benefits in pursuing economic benefits, If this continues for a long time, the environment will be seriously polluted. Therefore, the control of environmental pollution can not stay in the attention of governments at all levels, but should deepen to the improvement of environmental awareness of every citizen of the whole nation. We should not only achieve economic development, improve living standards, but also achieve coordinated development of economic and environmental protection, and constantly improve the quality of life. To this end, we need to call on people to fulfill their responsibilities for the realization of the Sustainable Development Goals in the 21st century, for the survival of human health and for the environment of future generations.

The growth course of China's sewage treatment industry in the past 50 years

(1) The situation in the 1950s and 1960s

Since industrial and agricultural production had just started in the early days of liberation, the sewage pollution level was very low at that time, and the use of sewage for agricultural irrigation was advocated, especially in the water-scarce areas in northern China, and the use of sewage irrigation was promoted as an experience, such as Shenfu Irrigation Canal. Therefore, only a few cities in the country have built nearly ten sewage treatment plants (including three sewage treatment plants built by foreigners from 1921 to 1926), and some are still first-level treatment in the treatment process, and the scale of treatment is also very small, only several thousand m3 per day, and the largest is only about 50,000 m3 per day. Resulting in sewage treatment technology and management level in a relatively backward state.

(2) The development and changes in the 1970s and 1980s

With the continuous development of industrial and agricultural production and the gradual improvement of people's living standards, the composition of urban sewage has also changed, the pollution level has gradually evolved from low to high, and some developed capitalist countries have suffered painful lessons from the threat to people's health due to sewage pollution (such as the emergence of Japan's national bone pain disease and Minamata disease). Aroused people's attention and the Chinese government attaches great importance to the establishment of the national environmental protection organization (* Environmental Protection Office), the university has also set up the department of environmental engineering or environmental engineering, * Environmental protection Office invested in the construction of Tianjin sewage treatment pilot plant (Tianjin Jizhuang Zi sewage treatment pilot Plant), the construction began in the late 1970s, the scale of treatment: The primary treatment is 0.1m3 /s, the secondary treatment is 0.025m3 /s, and the Beijing Gaobeidian sewage treatment pilot Plant has also been in operation. The state and local governments are preparing for the construction of domestic large-scale sewage treatment plants to do preliminary work, at this time Tianjin Municipal government and the Ministry of Construction and relevant ministries decided to build Tianjin Jizhuang zi sewage treatment plant, and broke ground in 1982, completed and put into operation on April 28, 1984, with a processing scale of 260,000 m3/d。

The birth of Tianjin Jizhuangzi sewage treatment plant fills the gap in the construction of large-scale sewage treatment plants in our country, and has aroused great attention from the government. Ji Zhuangzi sewage treatment plant has been put into operation for many years to meet the design of effluent water quality standards, so that the black and smelly sewage into clear flow, which has been praised by the members of the committee, and through them to the governments across the country to accelerate the pace of construction of sewage treatment plants, the development of sewage treatment business, and the elimination of sewage pollution to the environment. Because Jizhuangzi sewage treatment plant is the largest urban sewage treatment plant in China, it has also aroused the great attention of various provinces and cities, and they have led teams to visit the plant, and their arrival will bring the seeds of sewage treatment to the motherland to blossom and bear fruit. Under their decision, Beijing, Shanghai, Guangdong, Guangxi, Shaanxi, Shanxi, Hebei, Jiangsu, Zhejiang, Hubei, Hunan and other provinces and cities have built sewage treatment plants of different sizes according to their specific conditions, so that China's sewage treatment plants have developed from a dozen in the 1960s to dozens.

The successful experience of design, construction and management of Tianjin Jizhuangzi sewage treatment plant has played a demonstration role in the construction of large-scale urban comprehensive sewage treatment plant in China, and has also laid the foundation for the large-scale development of sewage treatment industry in China in the 1980s.

(3) The development of sewage treatment technology and the achievements of sewage treatment plant construction at the end of the 20th century

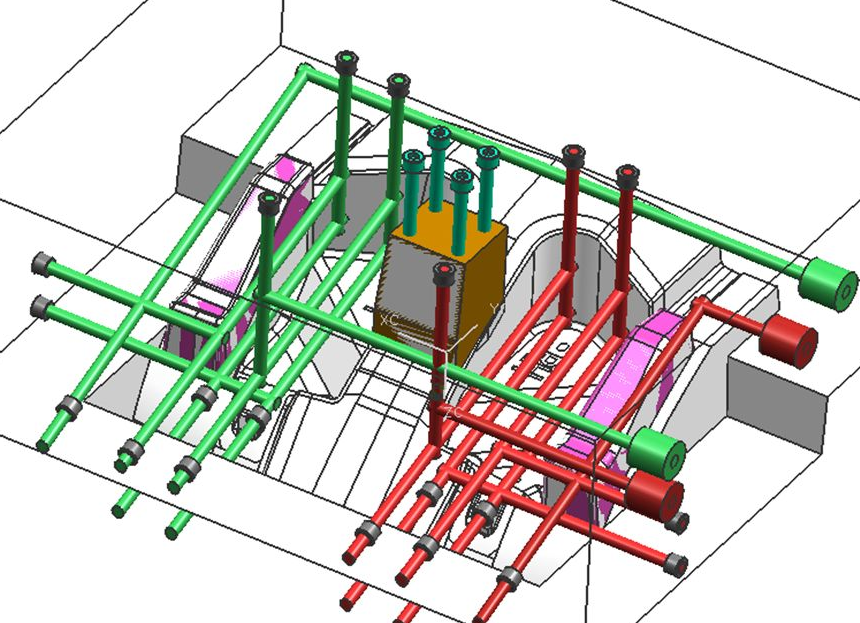

The establishment of the national "Seventh Five-Year Plan", "Eighth Five-Year Plan" and "Ninth Five-Year Plan" scientific and technological research topics has made gratifying scientific research achievements in China's new technology of sewage treatment, new technology of sludge treatment and new technology of recycled water reuse, and some projects have reached the highest level. Foreign sewage treatment technology, new technology, new equipment has been introduced into China, in the activated sludge process application at the same time, AB method, A/O method, A/A/O method, CASS method, SBR method, oxidation ditch method, stabilization pond method, land treatment method, etc., also in the construction of sewage treatment plants have been applied. From the past sewage treatment technology that only has the function of removing organic matter to the development of multi-functional process technology with phosphorus and nitrogen removal, some of the most advanced and foreign sewage treatment equipment has entered the market of China's sewage treatment industry. Such as grid machine, submersible pump, sand removal device, mud scraper, aerator, blower, sludge pump, dehydrator, biogas generator, biogas boiler, sludge digestion and mixing system and other large equipment.

Due to the large investment in the construction of large-scale urban sewage treatment plants, China's construction funds are limited, and can not meet the needs of water pollution control. Therefore, the introduction of foreign funds to construct sewage treatment plants has become an important part of the construction funds, which also speeds up the construction speed of China's urban sewage treatment plants. A number of large-scale urban sewage treatment plants have been built and put into operation by using foreign loan projects. For example, Beijing Gaobeidian sewage plant, the largest sewage treatment plant in the 20th century in China, has a treatment scale of 500,000 m3/d in the first phase and up to 1 million m3/d in the second phase. The treatment scale of Hangzhou Sibao sewage Treatment plant is 600,000 m3/d; The treatment scale of Tianjin Dongjiao sewage treatment plant, Chengdu Sanwa Kiln sewage treatment plant, Shenyang Northern sewage treatment plant and Zhengzhou Wangxinzhuang sewage treatment plant is 400,000 m3/d. The construction of these large sewage treatment plants marks the growing of our sewage treatment business, the development of sewage treatment technology in our country, the importance of our government to sewage treatment business, and also indicates that our sewage treatment business has developed to a new stage.

The present situation and prospect of the development of urban sewage treatment in China

(1) The shortage of funds for the construction of sewage treatment plants

Although more than 100 sewage treatment plants have been built in China, they are still far from meeting the needs of urban industrial and agricultural production and people's lives, manifested in the treatment rate of a city itself is not high, that is, the amount of sewage treatment is not enough, and manifested in large cities have begun to carry out the planning and construction of sewage treatment plant construction. However, in small and medium-sized cities, especially in the northwest, the planning and construction of sewage treatment have not been included in the urban development agenda. One of the main reasons is that there is no special construction funds, and water pollution in some areas is becoming increasingly serious. If we wait for the investment of funds to build sewage treatment plants, the environment will tend to deteriorate, which will bring inconvenience to people's lives and harm people's physical and mental health. Therefore, we need to raise funds in various ways to speed up the treatment of water environmental pollution. To leave a beautiful living environment for future generations.

(2) The operation funds of the sewage treatment plant cannot be in place

At present, more than 100 sewage treatment plants have been built and put into operation nationwide, and less than one-third of them can operate at full capacity. Reasons for not running at full capacity: Most of them are caused by the operation of funds can not be in place, some provinces and cities do not collect sewage treatment fees, some only collect factories, enterprises, do not collect residents, some factories, enterprises, residents have been collected, but the fee standard is set very low, far from meeting the minimum cost required for the normal operation of sewage treatment plants. This has given rise to the practical problem of some sewage treatment plants treating as many tons of sewage as are available for funding. Such a long time can not play the construction of sewage treatment plant due benefits, will also make the instrument, equipment damage, but also can not play the role of professional management of sewage treatment plant.

(3) Maintenance of imported equipment and development of spare parts

Due to the large number of imported equipment into the sewage treatment industry, after several years of operation, the equipment will gradually appear damage of varying sizes, especially the maintenance and normal overhaul after the claim period. This requires technical personnel with professional skills to carry out, if you ask foreign experts to repair, maintenance costs will be greatly increased it is difficult to accept, if the imported equipment can maintain normal operation, it is necessary to train domestic professionals for the maintenance of imported equipment, so that they master maintenance skills to meet the maintenance standards of imported equipment. With the maintenance of professionals also have enough spare parts, especially some of the equipment to be eliminated will be introduced to China, spare parts will not be produced abroad, you need to domestic mapping, processing and manufacturing, only in this way can the imported equipment play its role, otherwise the damage of equipment, the lack of parts will affect the normal operation of the sewage treatment plant.

(4) There is a gust of wind in the selection of sewage treatment process, and the popular process is not selected according to the actual situation of the region

The choice of popular process is in the choice of sewage treatment process, the emergence of the simple pursuit of new technology, the pursuit of fashionable technology, do not consider the inlet water quality in the region, the water treatment amount and the use of effluent problems, in some sewage treatment plants have been built in our country, the inlet water quality is relatively low, but also choose AB method, the results can not be fully utilized, resulting in idle facilities and equipment. In some areas, the treated recycled water is directly used for agricultural irrigation, but also over-emphasis on phosphorus and nitrogen removal, the adoption of A/A/O method, increasing the construction investment and increasing the daily operating costs, and some individual areas in the construction of sewage treatment plants, see what the wind blew what process to take.

(5) The reclaimed water after sewage treatment is not fully utilized

Huge investment in the construction of sewage treatment plants, the treated recycled water can not be fully utilized, and even some areas will be treated recycled water and untreated sewage mixed together, and some areas do not recycle recycled water but discharged into the sea resulting in a waste of fresh water resources. At present, the world's fresh water resources are extremely scarce, and China's fresh water resources occupy the 121st place in the world, and the per capita fresh water occupancy is only 2000 m3.

(6) The sludge is not really harmless, and there is no way of final disposal

After the sewage has been treated by various processes, the effluent has reached the discharge standards stipulated by the state, but the sludge generated in the sewage treatment process has not been properly disposed of, and will cause secondary pollution to the environment. In some areas, the sludge does not go through harmless treatment, the sludge is shipped out, and it is not clear where the final place of the sludge is. In some areas, although the sludge has been digested and treated, the sludge has been stacked off-site and arbitrarily taken away. In some areas, the sludge is dried for agricultural fertilizer, and whether the heavy metal content is up to standard is rarely considered, and the analysis of how much harm to crops is insufficient. The national environmental protection department prohibits the sludge as a fertilizer for vegetable fields and rice fields, and as a agricultural fertilizer for dry fields, the composition of the sludge needs to be analyzed, and heavy metals and toxic substances can be used only if they do not exceed the standard. As a green fertilizer, sludge should be recognized by the garden department, and can be used only after tracking and analysis by the monitoring department. In short, if the sludge does not have the ultimate disposal way, it is a hidden danger of re-pollution to the environment.

(7) There is no deodorization device in the sewage treatment plant

Sewage treatment plant inlet pool, grilles, sedimentation tank, initial sedimentation tank and sludge storage tank of sludge treatment system, dewatering room (except centrifuge) will produce serious odor, not only affect the health of operation personnel, but also bring pollution to the living environment of surrounding residents, especially some early construction, the surrounding used to be farmland, pools, and sewage treatment plants far from the urban area. At present, it has become an urban area, built houses around the sewage treatment plant, formed a residential area, and the people around the sewage plant have suffered harm, and should solve the deodorization device through multiple channels, because the sewage treatment plant itself is an enterprise that eliminates pollution and protects the environment.

Future development trend

Economic development is coordinated with the development of sewage treatment

Economic development and water environmental pollution is proportional, that is to say, the faster the speed of economic development, the more serious the corresponding water environmental pollution. People's life is inseparable from water, industrial and agricultural production development is inseparable from water, discharged whether domestic sewage or industrial wastewater will bring different degrees of pollution. Economic development is the need for capital investment, to protect the environment from pollution, also need money, when funds are limited, it is necessary to economic development and environmental protection of the two hard indicators of organic coordination, can not cause the loss of one or the other or the situation. If economic development loses environmental protection, the environment will be seriously polluted, and no amount of money will be invested to clean the original environment. The negative lessons of foreign countries warn us that Japan's Ise Bay is polluted by coastal petrochemical production wastewater, which causes serious losses of aquatic products in Ise Bay and produces the consequence of being inedible, and it is difficult to restore the environmental condition before pollution after years of treatment. This also fully proves the close relationship between economic development and environmental protection. To avoid the further deterioration of environmental pollution, we need to take three measures:

(1) Capital construction projects should adhere to the synchronous implementation of the production line and pollution control. The environmental quality assessment report must be available when reviewing the feasibility study report of the project, the design of the production line and the pollution control design should be carried out simultaneously, the construction of the production line should be carried out simultaneously with the construction of the pollution control facilities, the production line should be put into operation at the same time as the pollution control equipment, and the production line without the "three simultaneous" conditions would rather not be on the production line, rather than let the new project start blindly. So as not to cause environmental pollution.

(2) Start from the reform of the production process, solve the pollution from the source, clean production, production of green products, such as cyanide-free electroplating, fluorine-free refrigeration, phosphorus free washing powder production, etc., are from the process to solve the pollution measures.

(3) For the production line that has been built and put into operation, if it is fined for pollution caused by no pollution control measures, it can not simply return the fine to the polluter, but put forward the requirements for treatment within a time limit, and help him develop an operable implementation plan to fundamentally solve the pollution situation, otherwise the polluter will pay pollution fines year after year without treatment. Because the penalty of eight out of ten policy is too favorable.

Support the development of domestic environmental protection industry (sewage treatment industry)

(1) Localization of sewage treatment equipment

Although the sewage treatment equipment has a certain professional personality, but also has the commonality of other industry equipment, as long as you understand the use of sewage treatment equipment, the role of the equipment in the treatment process and the technical "parameters" that the equipment should have, you will produce qualified applicable sewage treatment equipment, "Seven Five" period, National science and technology research topic 59-03-04-04 "Belt filter press localization research", the project results have been widely used in the domestic sewage treatment industry, its effect has reached the level of similar foreign products, for the country to save a lot of foreign exchange quota, thus indicating that the localization of sewage treatment equipment is feasible, many of the domestic large and medium-sized enterprises are machinery manufacturers, They have the basic quality of the machinery manufacturing industry, and then combine the professional characteristics and requirements of sewage treatment equipment to produce high-quality sewage treatment equipment is completely OK. This channel is also a good way for the machinery industry to seek survival in the future, and the state will give some preferential environmental protection industrial policies, then this enterprise will thrive, and at the same time reduce the number of foreign equipment purchased. More importantly, it fundamentally solves the actual problem that foreign equipment needs foreign professional maintenance personnel for maintenance and there are no spare parts after the elimination of foreign equipment.

(2) The development of sewage treatment instruments

The implementation of modern management of sewage treatment plants, can not be separated from sewage treatment instruments, and the domestic instruments used in our country are borrowed from chemical and thermal instruments, because the sewage treatment profession is different from the chemical and thermal industries, so the instruments often have problems in the operation and management of sewage treatment plants.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands