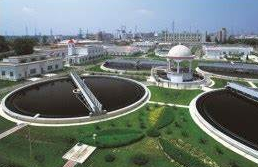

Municipal sewage treatment

Water volume change:

In the process of human production and life, most of the used water is discharged into the sewage pipe, but this does not mean that the amount of sewage is equal to the amount of water, because sometimes the used water is not discharged into the sewage pipe, such as fire fighting, street flushing water is discharged into the rainwater pipe or evaporated, coupled with the leakage of sewage pipes, resulting in the amount of sewage less than the amount of water. The amount of sewage in general cities is about 80% to 90% of the water. In addition, in some cases, the actual amount of sewage discharged into the sewage pipe may also be greater than the amount of water given, such as groundwater infiltration through the pipe interface, rainwater inflow through the inspection well, and factories or other users do not have dispersed water supply equipment, the amount of water given by these users may not be included in the urban centralized water supply, and so on, when the sewage may be greater than the amount of water given.

In different industrial enterprises, the exclusion of industrial wastewater is very inconsistent, the industrial wastewater of some factories is uniformly discharged, but the wastewater discharge of many factories changes greatly, and even the wastewater of some individual workshops may also be discharged in a short period of time, coupled with the emergence of new processes and new products in the factory, so that the quality of urban sewage water is also constantly changing. To sum up, the change of water quality and quantity of urban sewage is also related to the development of the city, the level of people's living standards, the number of sanitary appliances, the geographical location of the city, the climate and the season.

The design size of an urban sewage treatment plant facility depends on the total amount of industrial wastewater Q2 discharged into the sewers and the amount of sewage discharged with stormwater Q3 as well as the amount of sewage discharged by the urban population using the sewers.

Process used:

Urban sewage treatment technology is the use of various facilities and equipment and process technology to separate and remove the polluting substances contained in sewage from the water, so that the harmful substances are converted into harmless substances and useful substances, the water is purified, and the resources are fully utilized.

Urban sewage treatment technology usually has physical treatment technology, chemical treatment technology, physical chemical treatment technology, biological treatment technology and so on.

Typical physical treatment technologies used in urban sewage treatment include precipitation technology, filtration technology, air flotation technology, etc.

Typical chemical and physicochemical treatment technologies include neutralization, dosing coagulation, ion exchange and so on.

Typical biological treatment techniques include aerobic oxidative decomposition and anaerobic biological fermentation.

Urban sewage treatment process is actually the application and combination of these technologies.

Urban sewage treatment process: According to the process and treatment procedures, urban sewage treatment process can be divided into pretreatment process, primary treatment process, secondary treatment process, advanced treatment process and sludge treatment process, as well as the final sludge disposal.

preconditioning

The pretreatment process of municipal sewage treatment plant usually includes grid treatment, pump house pumping and sand settling treatment. The purpose of the grating treatment is to intercept the bulk material to protect the normal operation of the subsequent pump pipeline and equipment. The purpose of pumping the pump house is to raise the water head to ensure that the sewage can be gravity through the various treatment structures built on the ground. The purpose of sand settling treatment is to remove the sand, stone and large particles contained in the sewage, so as to reduce their settlement in the subsequent structures, prevent the sand deposition of the facilities, affect the efficacy, cause wear and blockage, and affect the normal operation of pipeline equipment. Primary treatment process: mainly the primary sedimentation tank, the purpose is to settle the suspended matter in the sewage as much as possible to remove, the general primary sedimentation tank can remove about 50% of the suspended matter and about 25% of BOD5.

Secondary treatment

It is mainly composed of an aeration tank and a secondary sedimentation tank. The aeration fan and a special aeration device are used to supply oxygen to the aeration tank. The main purpose is to change most of the pollutants in the sewage into CO2 and H2O through the metabolism of microorganisms, which is the oxygen consumption technology. Microorganisms in the aeration tank continuously flow into the secondary sedimentation tank together with water after the reaction, and the microorganisms sink in the bottom of the pool, and are sent back to the front end of the aeration tank through pipes and pumps to mix with the new inflow of sewage. The treated water clarified above the secondary settling tank flows out of the sewage plant continuously through the effluent weir.

Advanced treatment: is to meet the requirements of high standards of receiving water or return to industrial and other special uses for further treatment, common processes are coagulation precipitation and filtration. Chlorine requirements and contact pools are often added to the end of advanced treatment. With the high level of urban social and economic development, in-depth treatment is the need for future development.

Sludge treatment:

These include concentration, digestion, dehydration, composting or domestic landfilling. Concentration can be mechanical or gravity concentration, and the subsequent digestion is usually anaerobic medium-temperature digestion, that is, anaerobic technology. The biogas produced by digestion can be used as energy for combustion or power generation, or used for chemical products. The sludge produced by digestion is stable in nature and has fertilizer effect. After dehydration, the volume is reduced and cake is formed, which is conducive to transportation. In order to further improve the sanitary quality of the sludge, the sludge can also be manually composted or mechanically composted. Composted sludge is a good soil conditioner. The sludge with excessive heavy metal content should be disposed of carefully after dehydration treatment, and it is generally necessary to landfill and seal it.

Typical process:

The municipal sewage treatment process is still used in primary treatment, secondary treatment and advanced treatment, but the most popular at home and abroad is the traditional activated sludge process as the core of the secondary treatment.

The determination of urban sewage treatment process is determined according to the requirements of urban water environment quality, incoming water quality, available technology development, urban economic status and urban management operation requirements. Before the process is determined, it is generally necessary to undergo thorough investigation and research and economic and technical comparison. In recent years, there are many types of A-O or A-A-O process, SBR process, oxidation ditch process and so on. A-O or A-A-O processes are also called anoxic-aerobic or anoxic-anoxic-aerobic processes. The development of this process is mainly to meet the needs of nitrogen and phosphorus removal, which is an economical and effective biological deammonia and phosphorus removal technology, many sewage plants in southern China have adopted this process.

SBR process is also called sequencing batch activated sludge process. This process structure is mainly a pool for both aeration pool and secondary precipitation, simple management, especially suitable for small and medium-sized cities and towns of urban sewage treatment, for the continuous operation of large amounts of water, the treatment is generally several sets of pool combination operation. Oxidation ditch process is a delayed aerated activated sludge process, because the load is very low, the impact load is strong, the effluent quality is good, the sludge production is small and stable, and the operation management is simple. The oxidation ditch can be designed according to nitrogen removal, or it can be slightly modified to remove nitrogen and phosphorus. In addition, there are some variants of the traditional activated sludge method for urban sewage treatment, as well as some process types such as A-B process.

Industry development:

After the 1950s, the global population grew rapidly and industry developed rapidly. The global water situation is deteriorating rapidly. On the one hand, human demand for water is expanding at an alarming rate. On the other hand, increasingly serious water pollution eats away at a large amount of water available for consumption.

China's per capita water resources are small and their spatial distribution is unbalanced. With the acceleration of urbanization and industrialization in China, the demand gap of water resources is also increasing. In this context, the sewage treatment industry has become an emerging industry, and the tap water production, water supply, drainage, water reuse industry in the same important position.

In 2007, China's investment in water pollution control reached 338.76 billion yuan, an increase of 32 percent over the previous year, accounting for 1.36 percent of that year's GDP. China's water environment quality has remained stable on the whole. In 2007, 942 sewage outlets in primary water source protection areas were shut down, 1,294 construction projects that might cause pollution in secondary water source protection areas were suspended, and 931 projects were brought under control within a time limit.

By October 2008, 1,459 sewage treatment plants had been built in cities, counties and some key towns, with a daily treatment capacity of 85.53 million tons (288 in 36 big cities with a daily treatment capacity of 34.97 million tons), an increase of 60.5 percent and 42.6 percent over the end of the Tenth Five-Year Plan, respectively. The municipal sewage treatment rate increased from 52 percent in 2005 to 63 percent in 2007. A total of 1,033 urban sewage treatment projects are under construction, with a designed daily treatment capacity of 35.95 million tons. From January to October 2008, the country's urban sewage treatment plants that have been put into operation have treated 19 billion tons of sewage, and the operating load rate has reached 76%, an increase of 21% and about 3 percentage points respectively.

In the context of the international financial crisis, China has adopted the policy of continuing to expand domestic demand and promote economic growth, and has placed environmental protection in a prominent strategic position. Of the 100 billion yuan of new central government investment in the fourth quarter of 2008, 12 billion yuan was invested in energy conservation, emission reduction and ecological improvement. The investment in water pollution prevention and control projects in key river basins and the acceleration of the construction of urban sewage and garbage treatment facilities and sewage pipe networks amounted to 6 billion yuan, the former investment was 1 billion yuan and the latter was 5 billion yuan. It can be said that the sewage treatment industry has ushered in unprecedented development opportunities.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands