Bently 3500/50M tachometer module

Bently 3500/50M tachometer module

Product Overview

Core functions

The 3500/50M tachometer module is a dual channel module that can receive input signals from proximity probes or magnetic pickups, used to measure shaft speed, rotor acceleration, or rotor steering, and compare these measured values with user programmable alarm settings. When the set values are exceeded, an alarm is generated.

Main features

Multiple configuration options: supports multiple configurations such as speed monitoring, set value alarm, speed band alarm, zero speed notification, rotor acceleration alarm, reverse rotation notification, etc.

Signal supply: It can be configured to provide conditioned Keyphasor signals to the rear 3500 rack backplane without the need for separate Keyphasor modules in the rack.

Peak hold function: Stores the maximum speed, maximum reverse speed, or number of reverse rotations reached by the machine, and the peak value can be reset.

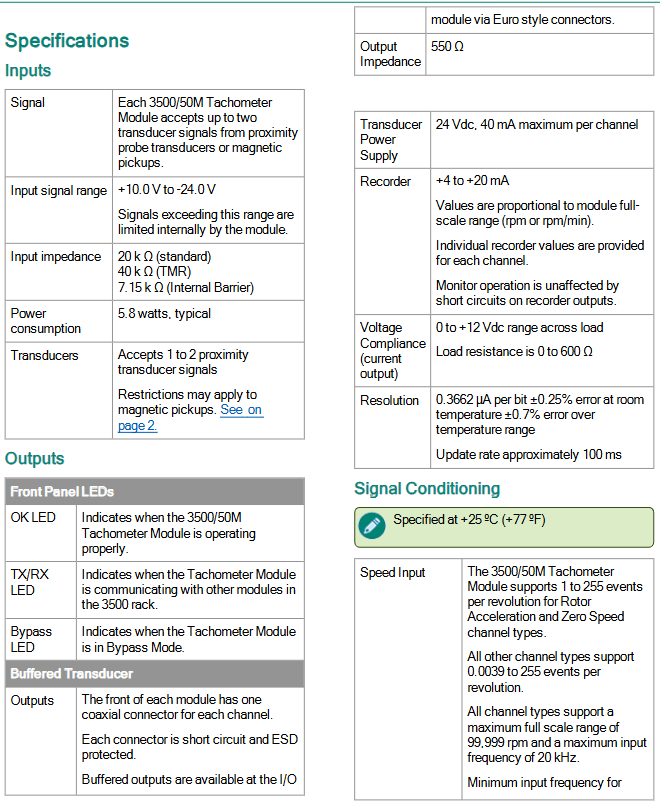

Technical specifications

1. Input parameters

Signal input: Each module can receive up to 2 sensor signals from proximity probes or magnetic pickups, with an input signal range of+10.0 V to -24.0 V. Signals outside the range will be restricted internally by the module.

Input impedance: The standard is 20 k Ω, TMR is 40 k Ω, and the internal barrier is 7.15 k Ω.

Sensor power supply: 24 Vdc, maximum 40 mA per channel.

Power consumption: Typical value of 5.8 watts.

Speed input: supports 1 to 255 events per revolution; The minimum input frequency of the proximity sensor is 0.0167 Hz (1 rpm at 1 event/rev); The minimum input frequency for passive magnetic pickups is 3.3 Hz.

2. Output parameters

Analog output: proportional to the module's full-scale range (rpm or rpm/min), each channel provides independent recorder values, and monitoring operations are not affected by recorder output short circuits; The voltage dependence of the current output is 0 to+12 Vdc (load resistance 0 to 600 Ω).

Resolution: 0.3662 µ A/bit, with an error of ± 0.25% at room temperature and ± 0.7% over the entire temperature range. The update rate is approximately 100 ms.

Front panel LED:

OK LED: Indicates that the module is operating normally.

TX/RX LED: Indicates that the module is communicating with other modules in the 3500 rack.

Bypass LED: Indicates that the module is in bypass mode.

3. Signal conditioning and accuracy

Threshold: The automatic threshold is applicable to any input above 0.0167 Hz (1 event/rev at 1 rpm), triggering a minimum signal amplitude of 1 V peak to peak; The manual threshold can be selected within the range of+9.5 Vdc to -23.5 Vdc, with a minimum trigger signal amplitude of 500 mV peak to peak.

Lag: Users can choose within the range of 0.2 to 2.5 volts.

Accuracy:

Speed accuracy: ± 0.1 rpm when<100 rpm; ± 1 rpm between 100 and 10000 rpm; ± 0.01% true shaft speed between 10000 and 99999 rpm.

Speed/minute accuracy: ± 20 rpm/min.

4. Alarm parameters

Alarm setting value: Each channel can set alarm level 1 (set value) for the measured value, which can be adjusted within the range of 0 to 100% of the full range of each measured value through software configuration.

Alarm delay: Alarm 1 has a delay of 1 to 60 seconds (1-second interval); Alarm 2 has a delay of 1 to 60 seconds (0.1 second interval).

Physical and installation parameters

Physical parameters

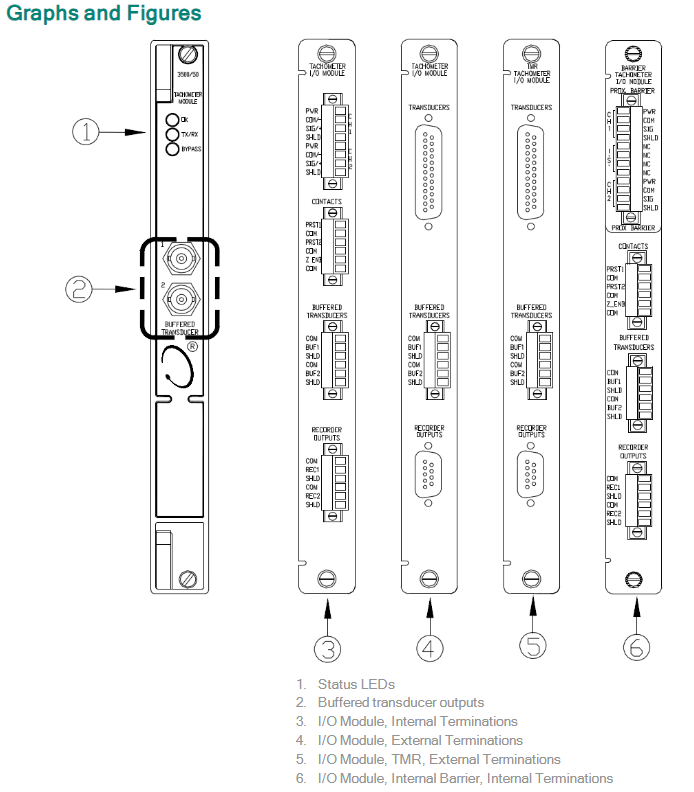

1. Monitoring module (motherboard)

Dimensions (height x width x depth): 241.3 mm x 24.4 mm x 241.8 mm (9.50 in x 0.96 in x 9.52 in)

Weight: 0.82 kg (1.8 lb)

2. I/O module

Barrier free I/O module

Weight: 0.20 kg (0.44 lb)

I/O module with internal barrier

Dimensions (height x width x depth): 241.3 mm x 24.4 mm x 163.1 mm (9.50 in x 0.96 in x 6.42 in)

Weight: 0.46 kg (1.01 lb)

Installation parameters

1. Rack space requirements

Monitoring module: occupying 1 full height front-end slot

I/O module: occupies 1 full height backend slot

2. Wiring and accessories

External terminal block (ET block)

To be used in conjunction with I/O modules with external terminals, terminal blocks and cables need to be ordered separately.

Supports European connectors and terminal block connectors, with specific models including 125808-05 (tachometer ET block, European connector), 128015-05 (tachometer ET block, terminal block connector), etc.

cable

Tachometer signal to ET block cable (135101-AAAA-BB): Available in lengths of 5 feet (1.5 meters), 7 feet (2.1 meters), 10 feet (3.0 meters), etc., supporting assembled or unassembled states.

Recorder output to ET block cable (129529-AAAA-BB): The length specification is the same as the above cable, and it also supports assembly or non assembly.

Installation restrictions

External terminal blocks cannot be used in conjunction with I/O modules with internal terminals.

I/O modules with TMR (Triple Modular Redundancy) require the use of bus type external terminal blocks.

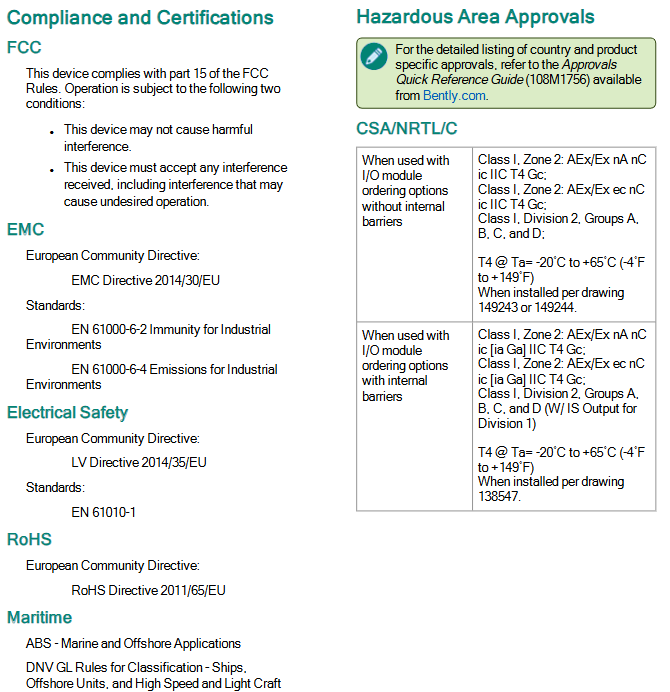

Environment and Compliance

Hazardous Area Certification: Supports CSA/NRTL/C, ATEX/IECEx and other certifications, suitable for Class I, Zone 2 or Division 2 hazardous environments (depending on whether the I/O module is equipped with internal barriers).

Electromagnetic compatibility (EMC): Complies with EN 61000-6-2 (industrial environment immunity) and EN 61000-6-4 (industrial environment emission) standards.

Electrical safety: comply with LV Directive 2014/35/EU and EN 61010-1 standards.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands