Tektronix 370B Programmable Curve Tracer

Key advantages: digital storage (flicker free display), precise cursor measurement (minimum resolution of 100pA), GPIB remote control, pulse mode (reducing device power consumption).

Tektronix 370B Programmable Curve Tracer

Basic Information and Quality Assurance Policy

Product positioning and applicable scenarios

Core function: Measure the static/dynamic characteristics of semiconductor devices and support the drawing of voltage current (V-I) characteristic curves for bipolar transistors, field-effect transistors (FETs), diodes, thyristors (SCR), and other devices.

Key advantages: digital storage (flicker free display), precise cursor measurement (minimum resolution of 100pA), GPIB remote control, pulse mode (reducing device power consumption).

Safety regulations and system installation

1. Core security requirements

Interlocking system: The test adapter must be equipped with a protective cover. When there is no cover, the collector power supply will be automatically disabled, and the red Warning light will turn off (the light will turn on when there is a cover, indicating dangerous voltage).

Live operation taboos: Do not plug or unplug when connecting the probe/test line to the voltage source, and do not remove the protective cover for measurement.

Power safety: Before replacing the power supply, it is necessary to cut off the power and confirm that the LINE VOLTAGE SELECTOR (115V/230V) matches the local power supply. The fuse specifications cannot be mixed (4A for 115V and 2A for 230V).

2. System installation process

(1) Power configuration

Confirm the LINE VOLTAGE SELECTOR on the Rear panel: select 115V/230V for NOMINAL and HIGH-LOW for RANGE (e.g. 115V HIGH corresponds to 107-132V).

Check fuses: Open the Rear panel fuse holder. For 115V models, use a 125V/4A fast melting fuse (159-0259-00), and for 230V models, use a 250V/2A fast melting fuse (159-0260-00).

Connect the power cord: Select the corresponding plug according to the region (such as standard plug for North America or A1 option plug for Europe).

(2) GPIB settings

Rear panel GPIB Terminator and Address switch: Set the address (0-31, 31 is offline) and select the termination symbol (EOI/LF).

Cable connection: Use standard GPIB cables (such as 012-0991-00, 2m) to connect the controller to 370B, with a maximum of 15 devices in the system.

Address verification: Press and hold the FAST/SHIFT+LOCAL keys, and the CRT will display the GPIB address and termination symbol.

(3) Test adapter installation

Standard adapters: A1001 (blank), A1002 (serial), A1005 (axial lead), align with A1006-A1010 interface during installation, and do not forcefully install double width adapters to the right interface.

Core Function Operation Guide

1. Key controls on the front-end panel

(1) Collector Supply Control

Key parameters of control item function description

MAX PEAK VOLTS selects peak voltage range 16V/80V/400V/2000V (4th gear)

MAX PEAK POWER selects maximum peak power of 0.08W/0.4W/2W/10W/50W/220W (6th gear)

Polarity selects 7 output polarities and modes:+LEAKAGE (measuring emitter current, sensitivity x 1000),+DC, AC, etc

VARIABLE regulates the output ratio from 0.0% to 100.0% (with a step size of 0.1%)

LOOPING COMPENSATION Compensation parasitic capacitance maximum compensation 100pF

(2) Step Generator Control

Key parameters of control item function description

OUTPUT MODE Select output type: current (50nA-200mA/step), voltage (50mV-2V/step)

NUMBER OF STEPS: Select the number of steps from 0 to 10 (only output offset when 0 steps)

PULSE selects the pulse modes SHORT (80 μ s), LONG (300 μ s), OFF

OFFSET adjustment offset ± 10 x step amplitude (step size 1%)

Inverted output polarity is only valid in EMITTER COMMON mode

(3) Digital Storage and Display Control

Storage mode:

NON STORE: Real time simulation display (no storage);

STORE: Digital storage (1024 points/axis, resolution 10 bits);

VIEW: Call the storage curve (16 IC memories/64 floppy disks).

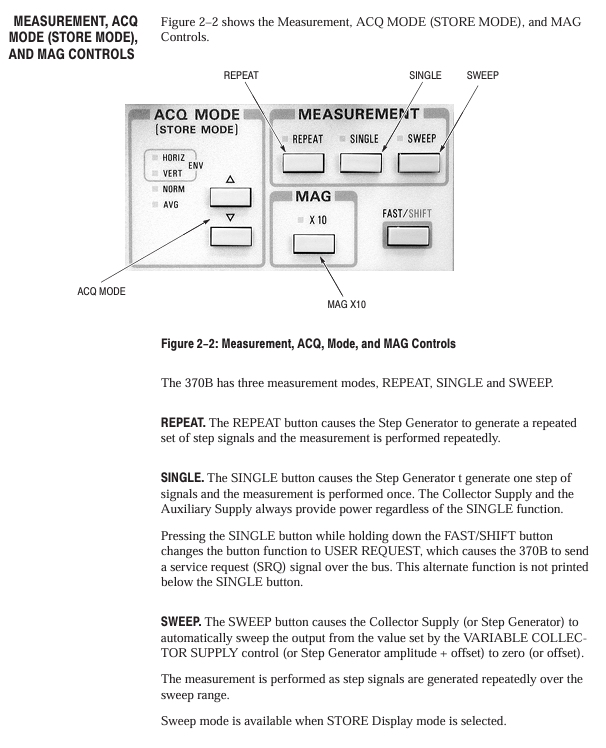

Collection mode:

AVG: 16 times average (noise reduction);

ENV: Vertical/Horizontal Envelope (Thermal Drift);

Norm: Conventional collection.

Cursor measurement:

DOT: Single point measurement (reading voltage/current);

F LINE: Functional line measurement (on resistance, intercept voltage);

WINDOW: Window measurement (hFE, gm).

2. Basic measurement process (taking diode forward characteristics as an example)

Install adapter: Insert the A1005 axial lead adapter into the right interface, insert the diode (anode connected to collector, cathode connected to emitter), and close the protective cover.

Configure collector power supply:

Choose 16V for MAX PEAK VOLTS, 0.4W for MAX PEAK POWER, and+DC for POLYTY.

Configure stepper generator:

Select CURRENT for OUTPUT MODE, 1mA/step for STEP AMPLITUDE, and 5 for NUMBER OF STEPS.

Start measurement:

Press MEASURE → REPEAT, adjust the VARIABLE collector power supply to 100%, and the CRT displays a positive V-I curve.

Cursor measurement:

Press CURSOR → DOT, move the cursor to the conductive area, and the CRT displays the forward voltage (such as 0.7V) and current (such as 5mA).

Typical measurement applications

1. Bipolar transistor (NPN type)

Measurement parameters: IC-VCE curve hFE、VCE (sat)、ICE0;

Key settings:

Configuration: CONFIG → BASE STEP GEN (emitter common ground);

Collector power supply: MAX PEAK VOLTS=80V, POLYITY=+DC;

Stepper generator: CURRENT mode, 50 μ A/step, 10 steps;

Measurement method: Use the WINDOW cursor to select adjacent curves, and the CRT will automatically display hFE (such as 250).

2. Field effect transistor (N-channel enhanced type)

Measurement parameters: ID-VDS curve gm、IDSS;

Key settings:

Configuration: CONFIG → BASE STEP GEN;

Collector power supply: MAX PEAK VOLTS=40V, POLYITY=+DC;

Step generator: VOLTAGE mode, 500mV/step, 8 steps;

Measurement method: Fit the ID-VGS curve with the f LINE cursor, and the slope is gm (e.g. 40mS).

3. Zener diode

Measurement parameters: reverse breakdown voltage (Vz), leakage current (IR);

Key settings:

Collector power supply: MAX PEAK VOLTS=400V, POLYITY=- DC;

Vertical sensitivity: 10 μ A/div (for IR measurement), 1mA/div (for breakdown current measurement);

Measurement method: The DOT cursor is positioned at the breakdown inflection point, and the CRT displays Vz (such as 12V).

GPIB remote control

1. Command format and examples

Basic format: keywords (abbreviations must include uppercase parts)+parameters, multiple commands separated by semicolons;

Example 1: Set collector power polarity: CSPOL PDC (PDC=+DC);

Example 2: Read the status of the stepper generator: STPgen? Return STPGEN NUMBER: 5, PULSE: OFF, OFFSET: 0.00, INVERT: OFF, MULT: OFF, CURRENT: 1.0E-3.

2. Data transmission process (waveform data)

Sending preamble query: WFMpre? Return waveform parameters (such as sampling point 1024, X-axis unit V);

Sending curve data query: CURVE? Return binary data (2-byte count+4096 byte coordinates+1-byte checksum);

Receiving data: The controller parses the data and converts it into a V-I curve (X=voltage, Y=current).

3. Common status codes

Suggestions for handling the meaning of status bytes (decimal)

65 power on completed normally, measurement can begin

97 command errors (such as syntax errors) check the command format, refer to Table 4-6

98 Execution error (such as parameter out of range) Confirm that the parameter is within the allowable range (such as AUX voltage ± 40V)

192 Device Specific Events (such as Full Floppy Disk) Replace Floppy Disk or Delete Old Data

Maintenance and troubleshooting

1. Self inspection process

Power on self-test: automatically detects ROM/RAM/buttons after powering on, displays SELETEST PASS as normal, flashes 0/1 indicates ROM error;

Detailed self-test: Press and hold FAST/SHIFT during startup, sequentially check the LED, display quality, and buttons, and press FAST/SHIFT to exit.

2. Common faults and solutions

Possible causes and solutions for the fault phenomenon

Collector power supply disabled (COL. Disabled) protection cover not closed, over temperature closed protection cover/waiting for cooling (COL. RECORDED prompt for recovery)

FD Read Error: The floppy disk is damaged and not formatted. Replace the floppy disk or perform formatting (FAST/SHIFT+SAVE → SAVE)

Insufficient cursor display intensity, mode error adjustment READOUT/CURSOR intensity, confirm in STORE/VIEW mode

3. Cleaning and maintenance

External cleaning: Use neutral cleaner and dust-free cloth to wipe the panel, and use ethanol to wipe the CRT;

Internal cleaning: Only qualified personnel are allowed to operate, use low-pressure compressed air (9psi) to blow off dust, and prohibit the use of high-pressure air (to prevent ESD);

Calibration cycle: It is recommended to calibrate once a year, referring to the performance verification process in Appendix A.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands