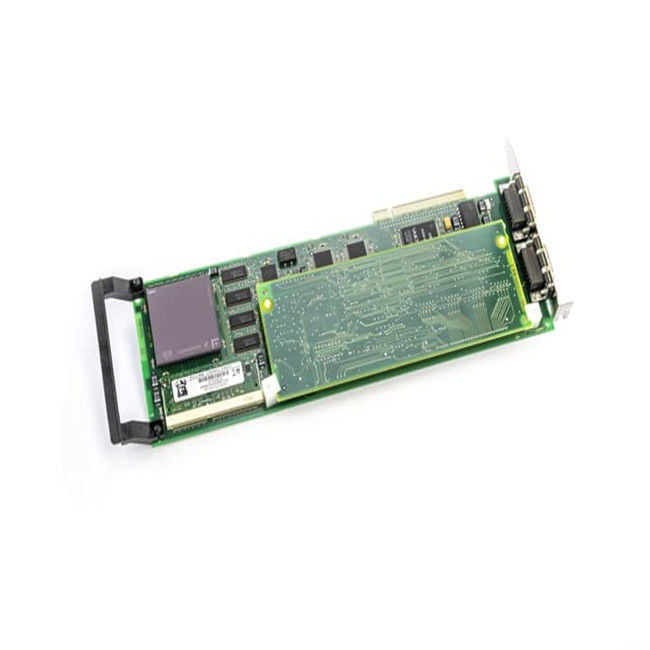

ABB 3BSE013064R1 PU516 Engineering Board -PCI

ABB 3BSE013064R1 PU516 Engineering Board -PCI

Brand Background

ABB, as a global leader in power and automation technology, has more than 100 years of technological precipitation and innovation accumulation. Since the merger of ASEA (Sweden) and BBC Brown Boveri (Switzerland) in 1988, ABB has always been driven by technological innovation, and has achieved pioneering results in three-phase power transmission systems, industrial robotics, high-voltage DC transmission and other fields, with operations in more than 100 countries around the world. With deep technical heritage and strict quality standards, ABB products in industrial automation, power systems and other fields set up the industry benchmark, providing efficient and reliable solutions for customers around the world.

Specification

Model No.: 3BSE013064R1 PU516 Engineering Board -PCI

Type: Engineering board, designed based on PCI bus architecture, for programming, configuration and debugging of industrial control systems.

Size: about 240mm×180mm×35mm, standard PCI board specification, suitable for most industrial control cabinets.

Interface: Equipped with PCI interface for system integration, supports RS-232/485 serial communication interface, Ethernet interface (10/100Mbps), convenient for data transmission and equipment interconnection; at the same time, there is a USB interface, which is convenient for programme download and system configuration.

Operating voltage: 24VDC ±10%, support redundant power input to ensure the stability of power supply.

Storage capacity: 8MB internal flash memory for storing programme and configuration data, 512KB RAM for running temporary data and system cache.

Operating temperature: -25℃~+60℃, adaptable to various industrial environments; relative humidity 5%~95% (non-condensing).

Certification: CE, UL, ISO 9001 and other international certifications, in line with industrial safety and quality standards.

Performance Advantages

Efficient programming and debugging: Designed for ABB control systems, it is deeply compatible with programming software such as Control Builder M. It supports various programming languages such as Ladder Diagram (LD), Function Block Diagram (FBD), etc., which enables engineers to quickly complete the programme development, downloading and on-line debugging, and significantly improves the project deployment efficiency.

Stable data interaction: With the high-speed data transmission capability of PCI bus, it can realise real-time data interaction with PLC, HMI and other devices to ensure fast and accurate transmission of control instructions and feedback information; the Ethernet interface supports Modbus TCP, Profinet and other industrial protocols, which is convenient for system integration and expansion.

High reliability design: industrial-grade components and anti-interference design, with short-circuit and over-voltage protection, stable operation in complex environments such as electromagnetic interference and vibration; on-board LED indicators show real-time operating status and fault information, which is convenient for quick positioning and maintenance.

Flexible scalability: supports multiple PU516 motherboards working in parallel, which can expand the system processing capacity; through the serial and Ethernet interfaces, it can be connected to remote I/O modules, sensors and other devices to meet the needs of industrial projects of different scales.

Notes

Installation Requirements: Install to standard PCI slot under power-off condition to ensure firm connection; avoid static damage during installation, and it is recommended to wear anti-static bracelet.

Environmental restrictions: Avoid use in high temperature, high humidity, strong corrosive gas environment; if applied in dusty environment, need to cooperate with dust-proof cabinet to prevent dust from entering the board to affect the performance.

Maintenance: Regularly check the connection cable and power status of the board; prohibit frequent hot plugging and unplugging of the device to prevent damage to the PCI interface; be sure to back up the original configuration before updating the programme to avoid data loss.

Similar Models

3BSE018166R1 PU517: The upgraded model of PU516, the storage capacity is increased to 16MB flash memory and 1MB RAM, which makes the processing speed faster; new dual Ethernet interfaces are added to support redundant network configurations, which is suitable for large-scale industrial projects with higher requirements for reliability and data transmission.

3BSE020150R1 PM630: Although it is not an engineering motherboard, it is also an ABB industrial control core module with integrated CPU, communication interface and I/O functions, suitable for small automation systems. Compared with the PU516, its programming environment and hardware architecture are different, suitable for scenarios that are sensitive to cost and space requirements.

Application Areas

Industrial automation production line: In automobile manufacturing, electronic assembly and other production lines, it is used for programming and controlling PLC system, achieving logical debugging of equipment, optimisation of process flow, and ensuring efficient and stable operation of the production line.

Process control system: in petrochemical, metallurgy, electric power and other industries, with the distributed control system (DCS), complete the temperature, pressure, flow and other parameters of real-time monitoring and control algorithms programming, to ensure that the production process is safe and efficient.

Intelligent building and energy management: Used in the program development of building automation system to achieve centralised control and energy optimisation of air-conditioning, lighting, lift and other equipment; in the energy management system, to improve the efficiency of energy use through data collection and analysis.

Mechanical equipment debugging: During the manufacturing process of machine tools, printing machines and other equipment, engineers use the PU516 to debug equipment functions and optimise parameters to ensure that mechanical equipment meets design requirements and performance indicators.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands