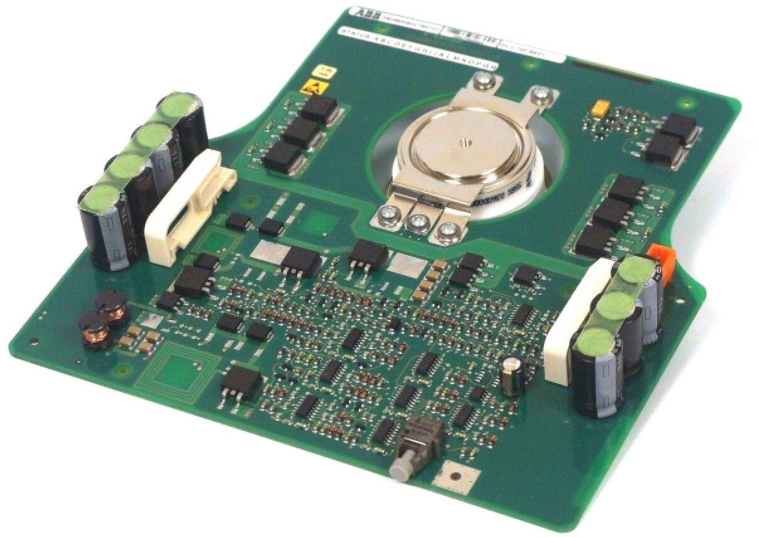

ABB 5SHX10H6004 Control Signal Processing Module

ABB 5SHX10H6004 Control Signal Processing Module

Product Overview

The ABB 5SHX10H6004 control signal processing module is a core component designed specifically for industrial automation and power system fields, mainly used for precise processing and conversion of various complex control signals. In industrial automation processes, sensors generate a large number of signals of different types and characteristics, such as analog signals, digital signals, etc. This module can quickly collect, filter, amplify, and convert these signals into standard signal formats that can be recognized and utilized by the control system, thereby ensuring the stable operation of the automation system. In the power system, it can be used to analyze and process signals related to the operation status of the power grid, assist in the monitoring and control of the power system, and ensure the reliability and safety of power supply.

Specification parameters

Input signal type: Supports analog signal input, with a typical voltage range of -10V to+10V and a current range of 4mA to 20mA. It is compatible with the output signals of various common sensors; Simultaneously supporting digital signal input, it can recognize standard TTL/CMOS level signals and adapt to signal output of different logic circuits.

Signal processing accuracy: For analog signal processing, it has an analog-to-digital conversion accuracy of 16 bits or even higher, ensuring that even small changes in the signal conversion process can be accurately captured, effectively reducing signal distortion; In terms of digital signal processing, it can achieve nanosecond level signal response and processing, meeting the stringent requirements for high-speed signal processing.

Processing speed: With a high-speed processor core, it can perform millions of signal processing operations per second, quickly analyze and convert input signals, and adapt to applications with high real-time requirements in industrial automation and power systems, such as fast speed control of motors, rapid detection and response of power system faults, etc.

Communication interface: equipped with multiple standard communication interfaces, such as RS-485 interface, supporting half duplex communication mode, with a communication distance of over kilometers, suitable for long-distance, multi node industrial field communication; The Ethernet interface supports TCP/IP protocol, which enables high-speed and stable data transmission, facilitates data interaction with the upper computer or other intelligent devices, and facilitates remote monitoring and system integration.

Working temperature range: Designed to adapt to a wide range of working environment temperatures, generally from -20 ℃ to 70 ℃, it can maintain stable working performance in common high and low temperature environments in industrial production, ensuring reliable operation in different regions and working conditions.

Power supply voltage: Supports 24V DC power supply, with good power adaptability, allowing the power supply voltage to fluctuate within a certain range (such as ± 10%) without affecting the normal operation of the module. At the same time, it has complete power filtering and overvoltage/overcurrent protection functions to ensure the safe operation of the module in complex power environments.

Core functions

Signal acquisition and conditioning: capable of simultaneously acquiring multiple analog and digital signals, filtering and processing the collected analog signals to remove noise interference, and amplifying the signals appropriately through amplifiers to achieve a suitable level range for analog-to-digital conversion; For digital signals, level matching and anti-interference processing are performed to ensure the integrity and accuracy of the signal.

Analog to Digital Conversion: Built in high-performance analog-to-digital converters (ADCs) and digital to analog converters (DACs). ADC can accurately convert analog signals into digital signals, facilitating subsequent digital signal processing and analysis; DAC can convert digital signals into analog signals for driving actuators that require analog control signals, such as motor speed controllers, valve controllers, etc., to achieve precise control of industrial equipment.

Signal analysis and processing: Using advanced digital signal processing algorithms to analyze the collected signals, such as spectral analysis, time-domain analysis, etc. Through spectrum analysis, harmonic components in the signal can be identified to determine whether there are abnormalities in the power system; Time domain analysis can be used to monitor the changing trends of equipment operation status, such as motor speed fluctuations, equipment vibration, etc., providing a basis for equipment fault diagnosis and preventive maintenance.

Communication and data transmission: Through its rich communication interfaces, the processed signal data is packaged and sent to the upper computer or other devices according to specific communication protocols, while also receiving control instructions from the upper computer, achieving remote control and data exchange. In industrial automation production lines, it can work in conjunction with programmable logic controllers (PLCs), distributed control systems (DCS), etc. to build a complete automation control system.

Precautions

Installation environment: It should be installed in a dry, well ventilated, non corrosive gas and dust free place, avoiding direct sunlight. The ambient temperature should be maintained within the operating temperature range specified by the product to prevent module performance from being affected by high or low temperatures. At the same time, it is necessary to stay away from strong electromagnetic interference sources, such as large motors, transformers, etc., to avoid interfering with signal transmission and processing.

Electrical connection: When making electrical connections, it is necessary to strictly follow the requirements of the product manual. Ensure that the specifications of the input and output signal lines and power lines are appropriate, the connections are secure, and avoid issues such as looseness, short circuits, or open circuits. Special attention should be paid to the correctness of the power polarity to prevent damage to the module due to power connection. At the same time, it is necessary to ensure good grounding, and the grounding resistance should meet the requirements of relevant standards to improve the anti-interference ability and safety of the system.

Parameter setting: Before being put into use, professional technicians need to correctly set various parameters of the module according to actual application needs, such as sampling frequency, signal range, communication baud rate, etc. Improper parameter settings may lead to signal processing abnormalities, communication failures, and other issues. After setting up, carefully check the parameters to ensure accuracy.

Maintenance: Regularly inspect and maintain the module to check for any damage to the appearance of the equipment and aging of the connecting cables. Regularly clean the dust on the surface of the module to prevent the accumulation of dust from affecting heat dissipation and electrical performance. At the same time, regular performance testing and calibration of modules should be conducted based on usage to ensure that they are always in optimal working condition. For some vulnerable parts, such as filter capacitors, communication interface chips, etc., they should be replaced regularly according to their service life.

Fault handling: When a module generates a fault alarm, the relevant equipment should be immediately stopped and the cause of the fault should be analyzed by referring to the product manual based on the fault indicator light or fault code. Do not forcefully restart the module until the fault has been resolved, in order to avoid more serious damage. For some simple faults, such as loose cables, incorrect parameter settings, etc., they can be self checked and resolved; For complex faults, it is recommended to promptly contact ABB's professional technical support personnel for maintenance and handling.

Model Supplement

ABB CH-3185 3BHL000986P1006

ABB 500MBA01 1MRB150003R0002 1MRB200053/L

ABB 500MBA02 1MRB150003R000/B

ABB 500MBA02 1MRB150003R0003 1MRB200053/M

ABB 3BHE022294R0103 GFD233A103

ABB 3BHE023784R1023 PP D113 B01-10-150000

ABB 3BHE004573R0145 UFC760BE145

ABB 3BSE076940R1 PM862K01 AC 800M

ABB PPD113 B03-23-100110 3BHE023584R2334

ABB XFD213A 3BHE028122R0001

ABB AO845A-eA

ABB D2D146-AA28-28

ABB DSMB-02C

ABB CTB810,HN800

ABB PNI800 Base MB805

ABB DSAO120

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands