Small products, big use! This chemical fiber "supporting role" is not a "walk-on"

Small products have great uses. Oil additives, masterbatch, these several small products seem to belong to the "supporting role", but in fact, they are related to the high-quality development of the "protagonist" chemical fiber products.

The "Guidance on the high-quality development of chemical fiber Industry" issued this year mentioned "improving the level of innovation and development of the industrial chain", "strengthen the key raw materials technology research, enhance the security and stability of the industrial chain"; In the mention of "promoting the high-end development of new fiber materials", it is proposed that "the research and development of key materials, auxiliary materials and flame retardants, modifiers, masterbatches, catalysts, oils, sizing agents and other products is the focus."

On November 16, the Annual meeting of chemical fiber Additives and masterbatch and industrial chain technical exchange Seminar, sponsored by China Chemical Fiber Industry Association and hosted by Chemical Fiber Additives Branch and co-organized by Zhejiang Chuanhua Chemicals Co., LTD., was held online. China Chemical Fiber Industry Association President Chen Xinwei, former vice president He Yanli, Vice president and Secretary-General Guan Xiaorui, Donghua University researcher Wang Huaping, China Chemical Fiber Industry Association oil additives Branch president, Zhejiang Chuanhua Chemicals Co., LTD. General Manager Pan Yi, Suzhou Baolidi Material Technology Co., LTD. Chairman Xu Yiming attended the meeting.

The meeting discussed the value, development status and demand direction of chemical fiber oil additives and masterbatches in fibers, the application of polyester, nylon, high-performance fibers and other subcategories, the problems still faced by "domestic" products in actual use, and how to improve the market competitiveness of localization "supporting roles".

Chen Xinwei, president of China Chemical Fiber Industry Association, pointed out: "Chemical fiber oil additives and masterbatches, as important raw materials, are important elements of innovation in the chemical fiber industry, and play a positive role in promoting the high-quality development of China's chemical fiber industry."

The level of localization of oil additives is not the same

The chemical fiber oil agent is used to adjust the friction characteristics of the fiber in the process of chemical fiber spinning, prevent or eliminate electrostatic accumulation, give the fiber smooth, soft and other characteristics, improve the fiber holding force, protect the fiber strength, reduce the spinning break rate, so that the chemical fiber smoothly through the spinning, stretching and other processes. At the same time, the quality of chemical fiber oil is directly related to the quality of the dyeing process.

Chen Xinwei introduced: "In recent years, the process of localization of chemical fiber oil additives continues to accelerate, polyester staple fiber, polyester DTY oil basically achieve self-sufficient supply, polyester POY, FDY and nylon oil to achieve domestic breakthrough, carbon fiber, arylon and other high-performance fiber oil additives development and application progress."

The total annual demand for chemical fiber oil agent in China is about 800,000 tons. In the polyester industry, the annual amount of DTY oil is about 550,000 tons, the amount of POY oil is about 100,000 tons to 110,000 tons, the amount of FDY oil is about 110,000 tons to 130,000 tons, and the amount of polyester staple fiber oil is about 50,000 tons.

"The pre-spinning agent used in the polyester industry is mainly imported, and the domestic oil agent still needs to be strengthened in the development of medium and high-end oil agents." New Fengming Group R & D manager Cui Li introduced.

In the nylon industry, Hengshen Group R & D department engineer Zheng Yulei introduced that the current total amount of nylon 6 oil is about 82,000 tons, of which DTY nylon 6 has the largest annual demand for oil, about 40,000 tons.

"China's nylon 6 oil agent started late. For the oils used in FDY and HOY products with higher requirements, Chinese oil suppliers still need to strengthen research and development." Zheng Yulei said.

In the spandex industry, Xie Yueting, chief engineer of Xinxiang Chemical Fiber Co., LTD., introduced that the oiling rate of 40D spandex is about 4.5%-5%, and the annual demand for spandex oil is about 43,400 tons in 2021, when China's 868,000 tons of spandex production is calculated, of which the market share of domestic oil is about 70%.

Zhejiang Chuanhua Chemical Co., Ltd. is a leading enterprise in the production of domestic oil, its polyester, nylon DTY oil in the domestic market share of more than 40%, in the global market share of more than 30%. For example, its research and development of conventional FDY oil agent TF-7611, TF-7616 and other products, in large polyester enterprises have achieved the undifferentiated replacement of imported products.

Lu Shuhui, engineer of Chuanhua Chemical Research and Development Center, said that at present, the market share of domestic DTY oil has reached nearly 90%, but the market share of domestic FDY oil is less than 20%, and the market share of domestic POY oil is less than 10%, and the former spinning oil needed by China's chemical fiber industry still relies heavily on imports.

Especially in the high-performance fiber industry of strategic materials related to national defense, the role of treatment agents, including oil additives and sizing agents, is very important.

"The treatment agent is a molecule that accumulates on the surface of the fiber, like a 'cosmetic' for the fiber." Zheng Guo, professor of Tianjin University of Technology, introduced that the interface treatment technology of high-performance fiber is very important, although the amount of treatment agent used in the production is very small, but the fiber spinning forming, smooth drafting, high temperature treatment, improve the fiber quality and performance are crucial。

At present, the amount of treatment agent required for high-performance fiber in China is about 9,000 tons per year.

Color masterbatches and functional masterbatches differ in performance

Masterbatch is the core raw material for chemical fiber to achieve the coloring and functional modification of the stock solution.

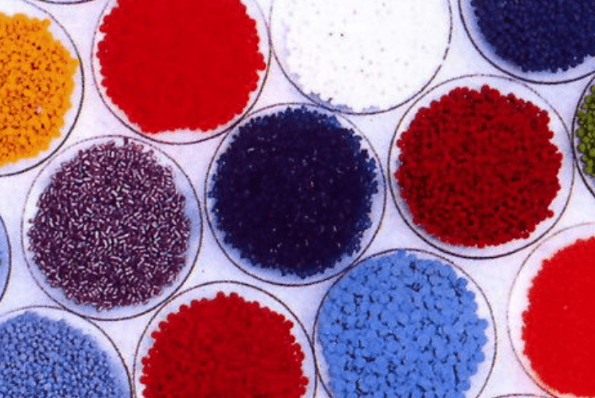

Chen Xinwei introduced that with the technological progress of dye industry, electronic color matching technology and masterbatch carrier, China's fiber masterbatch industry has achieved rapid development, the total demand of about 200,000 tons per year, has black masterbatch, dull masterbatch, color masterbatch and functional masterbatch, as well as outdoor supplies, automotive interior with high sun resistance masterbatch and other rich and diverse products. Among them, the masterbatch of automobile interior fabric breaks the foreign monopoly and realizes the localization replacement; Some color masterbatches and functional masterbatches meet the requirements of military fiber production and application.

By category, China's color masterbatch industry has developed rapidly in recent years, and the production enterprises are mainly distributed in Jiangsu, Zhejiang, Fujian and Guangdong.

Suzhou Baolidi Material Technology Co., Ltd. is a leading enterprise in the masterbatch industry in China, specializing in liquid coloring and functional modification of chemical fiber masterbatches, with an annual capacity of 60,000 tons of masterbatches, mainly covering polyester and nylon 6 two series and 10 series products.

Polaroid's products are mainly black and white and color masterbatches. Xie Wei, director of research and development of the company, said that the stock solution coloring technology can reduce the post-dyeing and finishing process, reduce the emission of waste gas and wastewater, greatly save the "post-pollution" phenomenon of the production water of textile enterprises and chemical dyes, green environmental protection, and the market demand has increased year by year in recent years. In particular, it will play a positive role in the process of implementing the goal of "carbon peak" and "carbon neutrality" in the country.

Due to the trend of green development, the market demand of color masterbatch has increased rapidly in recent years.

"The new Fengming Group mainly uses a lot of black masterbatch." Cui Li introduced that the company's annual consumption of black masterbatch is tens of thousands of tons, some of which are produced by themselves and the other part is purchased externally.

The development of functional masterbatch in our country has also made a certain breakthrough. For example, Polaridi's functional masterbatches include antibacterial, flame retardant, anti-static, luminous and other types, and in the past two years, it has also developed light-colored heating masterbatches, anti-counterfeiting tracking masterbatches, aerogel masterbatches and other innovative products.

Xie Wei introduced that the company's light-colored heating masterbatch has a good light-heat conversion efficiency, which can convert light energy into heat energy, and has been used in some mountaineering clothing and winter textiles; The anti-counterfeiting tracking masterbatch is used in the recycled fiber industry and can be traced to the manufacturer of the recycled fiber.

However, there is still a big gap between China's functional masterbatch and foreign countries, and the functional research of masterbatch mainly focuses on flame retardant masterbatch, antistatic masterbatch, toughening masterbatch and other aspects, and the functionality is still not rich and diversified.Ji Peng, associate researcher of Textile Science and Technology Innovation Center of Donghua University, pointed out that the design, preparation and application of fiber masterbatch involve complex technology, strict quality control, long research and development cycle, and high preparation cost, which has always been the high point of the international fiber market competition.

"China is in urgent need of collaborative research on key functional material preparation technology, masterbatch efficient preparation technology, spinnability quality control, and fiber application." Ji Peng said.

"Domestic goods" urgently need to supplement the weak board

At this stage, with the scale and industrial chain advantages of leading chemical fiber enterprises becoming more obvious, the demand for oil agents is growing, and the production technology and innovation ability of oil agents are also put forward higher requirements, especially the demand for oil stability is more prominent.

"The spinning speed of melt direct spinning of large polyester enterprises is very fast, and the spinning speed of some varieties reaches 5000 meters/minute, and the spinning speed of POY products is usually 3000 meters/minute." In the case of such a high spinning speed, the oil loading time is very short, generally only 0.01ms-0.02ms. In such a short time, how to ensure that the oil is evenly dispersed on the surface of the fiber is very demanding, but also to ensure that the fiber has a low coefficient of friction." Cui Li introduced, "In particular, whether the oil of POY products is uniform will also affect the elastic wire. For example, the hot box temperature of the elastic wire reaches 180 degrees Celsius, and the hot box temperature of some special elastic wire is even as high as 200 degrees Celsius, which puts higher requirements on POY oil agents."

However, whether it is polyester or nylon enterprises, the general feeling in the process of using domestic oil and imported oil is that "the stability of domestic oil needs to be improved."

The function and quality of masterbatch also need to be improved, and the functional masterbatch required by some differential fibers is missing, and it is necessary to strengthen targeted research in the field of segmentation. In addition, relevant standards need to be improved.

In the next step, how to strengthen the advantages of the industry at the same time, to further supplement the weaknesses, strong and weak items?

Pan Yi said: First, it is necessary to build an interactive platform between oil additive production enterprises and chemical fiber production enterprises; Second, we should continue to further promote the research work of the oil additives industry, and form a stable communication channel and information notification mechanism in the industry; Third, explore the cooperation mechanism between the oil Additives branch and the National Advanced Functional Materials Innovation Center; Fourth, we should continue to improve the technical standards of the oil industry, promote the sound development of the industry, and focus on promoting the industry standards of polyester, nylon FDY and POY; Fifth, we should strengthen the industry self-discipline, regulate the industry behavior, avoid disorderly competition, jointly promote the healthy development of China's oil additives industry, and enhance the market competitiveness of China's oil additives.

Chen Xinwei suggested: First, the independent innovation ability of enterprises still needs to be enhanced, and it is necessary to further strengthen the basic application theory research, achieve technological breakthroughs and realize industrial application, and ensure the stability and security of the industry; Second, the product structure still needs to be optimized, the special oil for the localization of high-end fiber products has not been completely solved, and high-grade and high-quality masterbatch manufacturers are still fewer; The third is to strengthen the effective collaborative innovation and development of the upstream and downstream of the industrial chain, and relevant enterprises should take the initiative to carry out joint research and development with chemical fiber enterprises and raw materials enterprises. Fourth, the level of green development still needs to be improved, the green, environmental protection and performance of raw materials need to be further enhanced, and the recycling technology also needs to be further studied.

"Sufficient supply and stable quality of chemical fiber oil additives and masterbatches are the prerequisite for safe selection by the chemical fiber industry." Only by solving these problems can we provide more possibilities for the chemical fiber industry to further improve quality and develop functional fibers." Chen Xinwei said.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands