Siemens 6AV6642-0DA01-1AX1 SIMATIC OP177B Industrial Human Machine Interface (HMI)

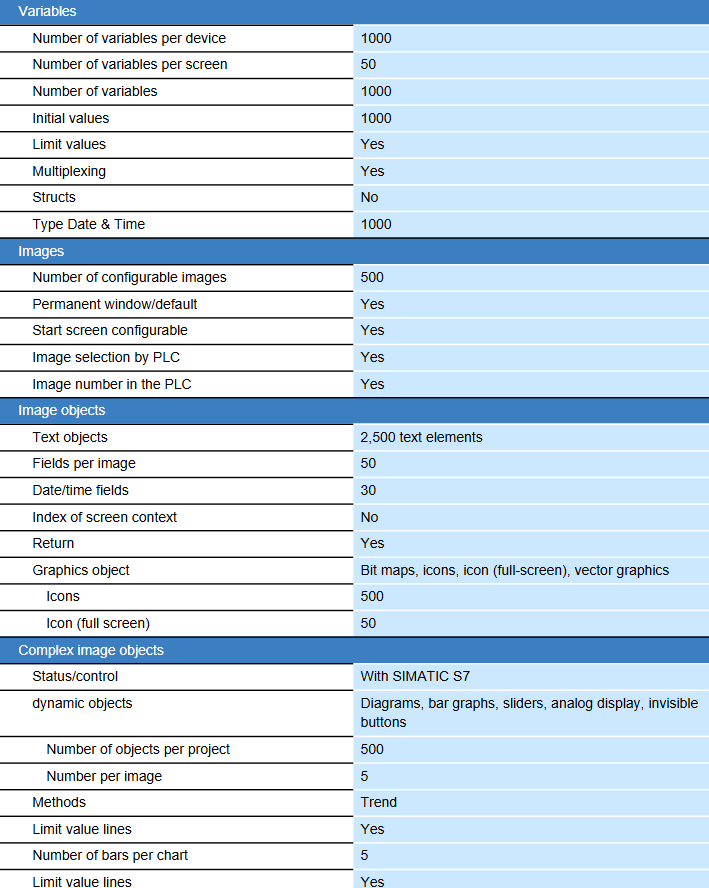

Object elements: Each project supports up to 500 objects, each screen supports 5 dynamic objects (such as trend chart, bar chart, slider, analog display, hidden button), supports 2500 text elements, 30 date/time fields, 500 icons (including 50 full screen icons);

Variable management: A single device supports 1000 variables, each screen supports 50 variables, supports initial and limit value settings, supports variable multiplexing, but does not support structural variables;

Process value display: Supports displaying process values in numerical, textual, and graphical formats (such as bar charts and trend charts), with a maximum of 5 data bars per trend chart and support for displaying limit lines.

(2) Alarm and Log

Alarm management: supports 2000 bit messages and 50 analog messages, up to 32 alarm categories, and supports 99 confirmation groups;

Log function: with alarm buffer and confirmation mechanism, supporting alarm log printing (including color printing and hard copy), supporting shift report generation (handover report);

Message configuration: Each message has a maximum length of 80 characters, supports displaying 8 process values in association, and supports system messages (HMI self status) and PLC messages (controller fault/status).

(3) Formula management

Formula capacity: Supports up to 100 formulas, with each formula containing 200 data records and each data record containing 200 entries;

Storage Expansion: Basic recipe storage of 32 KB (integrated with Flash), expandable storage capacity through MMC/SD card, suitable for multi product production scenarios (such as quick switching of process parameters for different specifications of products).

(4) Security and Permissions

User management: supports 50 user groups, 32 user permission levels, and can assign operational permissions according to roles (such as operators can only monitor, administrators can modify parameters);

Password function: Supports password import/export, records up to 1000 password error attempts, and enhances system security.

Environmental adaptability and certification

1. Environmental parameters

Working temperature: not clearly indicated, refer to storage/transportation temperature (-20 ℃~+60 ℃), suitable for most industrial workshop environments (extreme high/low temperatures should be avoided);

Relative humidity: maximum 90% (non condensing, to avoid circuit faults caused by moisture);

Transportation/storage temperature: -20 ℃~+60 ℃, meeting the needs of logistics transportation and warehouse storage.

2. Compliance certification

This product has passed multiple international industrial certifications and is suitable for applications in multiple regions around the world

Safety certification: CE, UL, CSA, cULus;

Hazardous environment certification: FM Class I Div. 2, EX Zone 2/22 (can be used in non explosion proof areas such as chemical, oil and gas hazardous areas);

Classification certification: GL, ABS, BV, DNV, LRS (some models support, can be used for ship automation systems);

Electromagnetic compatibility: Complies with industrial EMC standards, has strong anti-interference ability, and is suitable for complex electromagnetic environments (such as workshops with dense motors).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA