Emerson PACSystems RX3i I/O Module

Emerson PACSystems RX3i I/O Module

Product positioning and core values

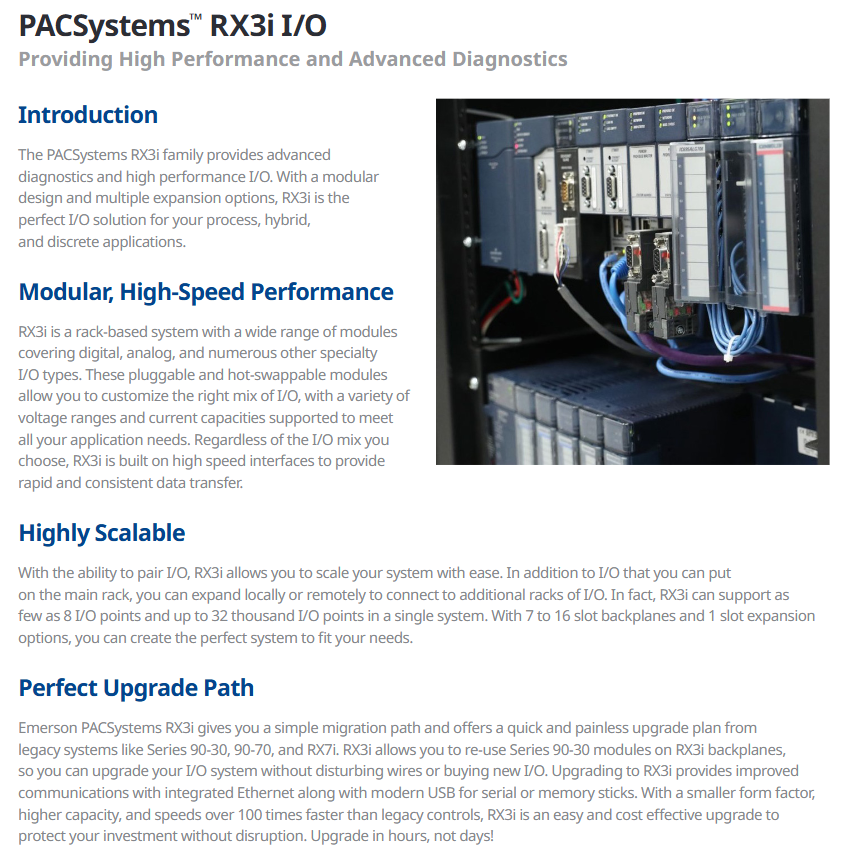

PACSystems RX3i I/O is a modular industrial grade input/output system launched by Emerson, designed specifically for process control, hybrid control, and discrete control scenarios. Its core advantages lie in high-performance data transmission, flexible scalability, and comprehensive diagnostic capabilities, which can adapt to automation needs from small and medium-sized equipment to large and complex production lines. At the same time, it provides a convenient legacy system upgrade path to protect users' existing investments.

Core Features and Advantages

1. Modular design and high-speed performance

Rich module types: covering digital quantities (voltage, relay output), analog quantities (voltage/current, RTD, thermocouple), and special I/O (high-speed counter, PWM pulse output, strain gauge acquisition, event sequence SoE input), supporting different voltage ranges (such as 24Vdc, 120Vac) and current capacities to meet diverse industrial signal processing needs;

Hot swappable function: All I/O modules support hot swappable, allowing for module replacement without the need to power off, reducing maintenance downtime;

High speed data transmission: Based on high-speed backplane interface, it ensures fast and stable transmission of I/O data, with response speed far exceeding traditional control systems, and is suitable for scenarios with high real-time requirements (such as motion control and precision process adjustment).

2. High scalability and flexible deployment

Customizable scale: A single system supports 8-32000 I/O points, providing various specifications of backplanes such as 7-slot, 12 slot, 16 slot, and 1-slot expansion units, which can be flexibly combined according to application scale;

Multi scenario expansion: Supports local expansion (main backplane overlay expansion backplane) and remote expansion (connected to remote I/O racks through Ethernet or serial bus), with a maximum of 448 I/O points supported by a single drop, suitable for decentralized device layout (such as multi area control in large factory areas);

Media compatibility: support copper cable, SM Fiber, and MM Fiber, and adapt to different transmission distance requirements (such as long-distance communication across buildings in the plant).

3. High availability and redundancy guarantee

Multi level redundancy:

Network redundancy: Supports Media Redundancy Protocol (MRP) and dual LAN architecture to avoid single network link failures;

System redundancy: compatible with PROFINET system redundancy (PNSR) and Ethernet global data (EGD), achieving bumpless switching over between controllers and I/O systems;

I/O redundancy: Key I/O channel redundancy can be configured through application code to further enhance system reliability;

Anti interference and environmental adaptability: Equipped with * * galvanic isolation * * (supporting both digital and analog input and output), strong anti electromagnetic interference capability; The default working temperature is 0-60 ℃, with optional -40~60 ℃ wide temperature version and normal coating (moisture-proof, dust-proof), suitable for harsh industrial environments.

4. Convenient maintenance and compatibility

Easy to connect design: All modules are equipped with pluggable terminal blocks, supporting solid/multi strand wires of 0.081~1.5mm ² (28~14AWG), providing both spring and box terminal types, supporting Terminal Block Quick Connect (TBQC) and forward fixation to ensure stable wiring;

Legacy system upgrade friendly: Series 90-30 modules can be directly reused on the RX3i backplane without rewiring or replacing I/O devices, and the upgrade process only takes a few hours (instead of the traditional solution of days); Simultaneously integrating Ethernet and USB interfaces to replace outdated serial interfaces, enhancing communication flexibility and speed (over 100 times faster than legacy systems).

Detailed explanation of technical specifications

1. Hardware and environmental parameters

Category specific parameters

Installation methods: Panel Mount, Rack Mount

Protection level IP20 (dustproof, preventing fingers from entering)

Working temperature standard: 0-60 ℃; Optional wide temperature range: -40~60 ℃

Isolation performance: All DI/DO/AI/AO channels support galvanic isolation to reduce ground current interference

Terminal specifications: Low density terminals support up to 12AWG wires, while high-density terminals support up to 14AWG wires

Certification standards UL, UL Hazardous Area Certification (Class I Division 2), CE, ATEX Zone 2; Some models support classification certification (ABS, BV, DNV GL)

2. Network and communication capabilities

Core network interfaces: PROFINET, Modbus/TCP, Ethernet Global Data (EGD), Control Memory Switching (CMX), PROFIBUS DP;

Gateway/Bridge Function: Supports serial communication Modbus/RTU、HART、GENIUS、DNP3 Serial/TCP、IEC-61850、IEC-104、 Reflective Memory, CANOpen, etc. can seamlessly integrate with devices from different manufacturers, such as instruments, frequency converters, and third-party PLCs;

Communication port: equipped with 2 RJ45 Ethernet ports and 2 SFP optical ports, supporting flexible switching between fiber and copper cables.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA