Woodward 723PLUS Digital Controller

Woodward 723PLUS Digital Controller

Describe

This manual introduces the hardware related content of the Woodward 723PLUS digital controller (models 9906-619, 9906-620, 9906-700), including general information, installation, control setpoint input, use of Servlink and Watch Window, product support and service options, etc. The controller is suitable for various application scenarios that require speed control.

General information

Application scenarios: It can adapt to various applications through programming. The hardware includes two speed inputs, supports two magneto electric sensors (MPUs) or proximity switches (such as for torsional filtering), as well as four analog inputs, three analog outputs, eight discrete inputs, and three discrete outputs, which can be used in load sharing systems. Its two LON channels can support related control functions.

Control options: Different models have different power input voltage requirements, and discrete input voltage provides switch command signals for control. There are also various other control options, such as proximity switch input suitable for low-frequency speed signals, 0-1mA output of instrument drivers, etc. The controller can be used in conjunction with proximity switches or magneto electric sensors with minimum frequency requirements.

Attachments: including handheld programmer (9907-205), SPM-A synchronizer, power output sensor, active power sensor, etc.

install

Scope: This includes general installation instructions for the 723PLUS controller, including power requirements, environmental precautions, location considerations, as well as unboxing, electrical connections, and installation inspection procedures.

Unpacking: Before handling the controller, it is necessary to read the relevant content on electrostatic discharge protection. When unpacking, be careful and check whether the controller is damaged. If there is any damage, immediately notify the shipper.

Power requirements: High voltage models require a 90-150Vdc voltage source, while low voltage models require an 18-40Vdc voltage source. To prevent damage to the controller, the input voltage range must not be exceeded. If battery power is used, an AC generator or other battery charging equipment must be equipped.

Location considerations: When selecting the installation location, factors such as ventilation, maintenance space, liquid and condensation prevention, electromagnetic interference prevention, and vibration prevention should be taken into account. The controller should not be installed on the prime mover, and the operating temperature range is -40 to+70 ° C (-40 to+158 ° F).

Specific installation requirements for marine use: The certification requirements for marine use types may change over time. In order to meet these requirements, all wiring, except for the part near the control connection terminal, must be inside metal conduits, and the control must be installed on a grounded metal mounting plate. It is also possible to meet attenuation requirements at specific installation locations or methods without additional special measures, but consultation with the shipyard is required.

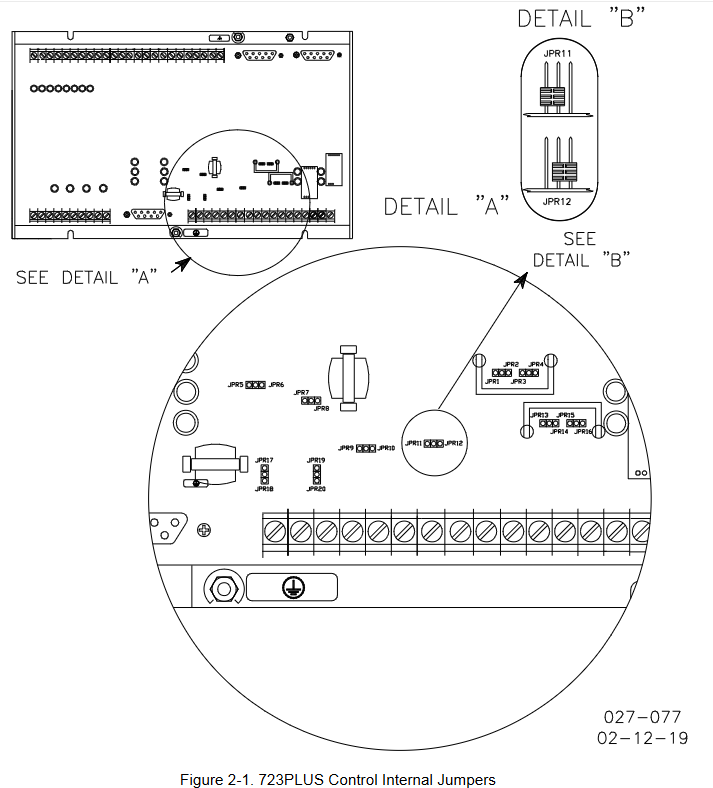

Internal jumpers: The 723PLUS controller has ten two position internal jumpers located at the top of the printed circuit board. If you need to change the jumpers, you need to read the electrostatic discharge protection content first, power off and wait before operating. Different jumpers have different default settings and functions.

Electrical connection: External wiring connection and shielding requirements should refer to relevant software manuals. All shielded cables must be twisted pair, signal lines should be shielded, and shielding layer connections should follow specific requirements. It also provides detailed instructions on the connection methods and precautions for power supply, analog output, actuator output, speed signal input, load sharing line input, discrete input, analog input, etc.

Installation inspection program: After installation, visual inspection (checking linkage devices, wiring, terminals, speed sensors, etc.) and grounding inspection are required to ensure that the resistance between each terminal of the controller and the chassis meets the requirements.

Serial port communication: The 723PLUS has two serial ports for communication, which can be configured into multiple types through software. When writing applications, it can be configured as a Modbus communication port and supports relevant protocols.

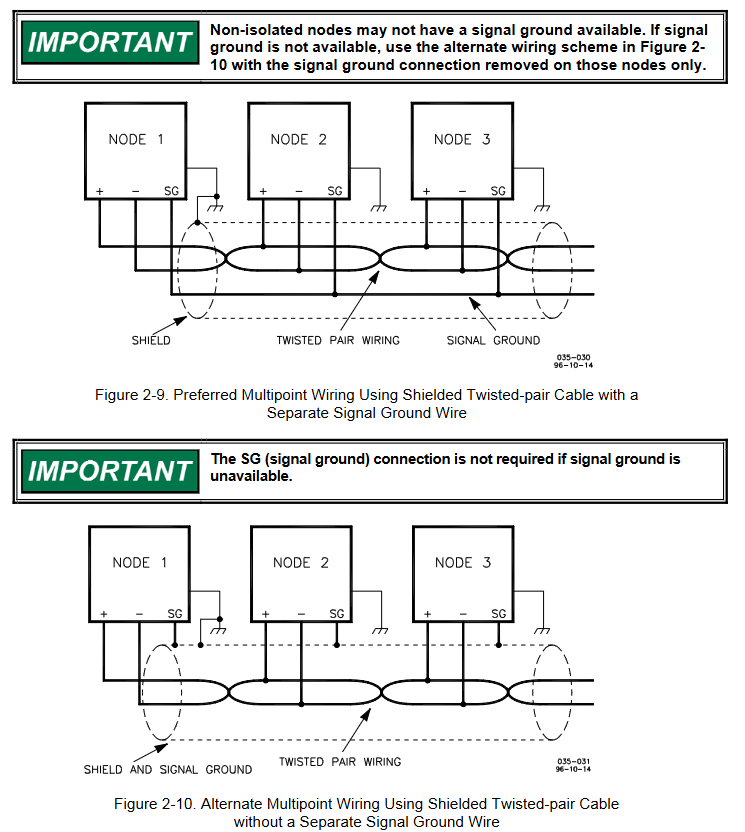

Terminal matching and grounding shielding: Different communication types (RS-422, RS-485) have different terminal matching requirements. RS-422 and RS-485 specifications require grounding wires when there are no other grounding paths between units. There are preferred and alternative wiring methods, and shielding and grounding must be handled correctly.

Control set point input

Overview: Due to differences in installation, system, and component tolerances, the 723PLUS controller must be adjusted for each system to achieve optimal performance. Setpoint inputs can be made through a handheld programmer or PC (using Watch Window software tools and Servlink software).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands