About half of China's new ship orders use new and clean energy

Keep up with the green and low-carbon trend

Research and development breakthrough orders increased

Since this year, aiming at low-carbon clean fuel power, the shipbuilding industry has frequently joined hands with shipping companies, and green ships have made new progress.

In the field of LNG fuel, in the first half of the year, Hudong Zhonghua delivered a total of 9 large LNG carriers, and the amount of new orders exceeded 20 billion yuan. China's share of the global market for large LNG carriers has increased to 35%.

In terms of power batteries, on July 26, the world's largest 700 TEU pure electric container ship built by Yangzhou COsco Shipping Heavy Industry was launched out of dock, with a endurance of 380 kilometers, which can achieve full electric navigation;

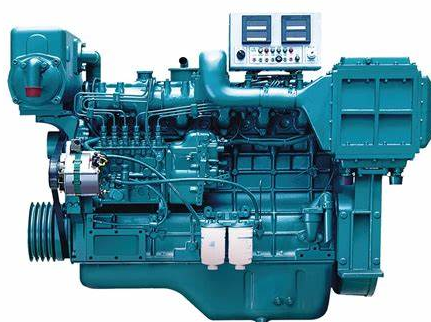

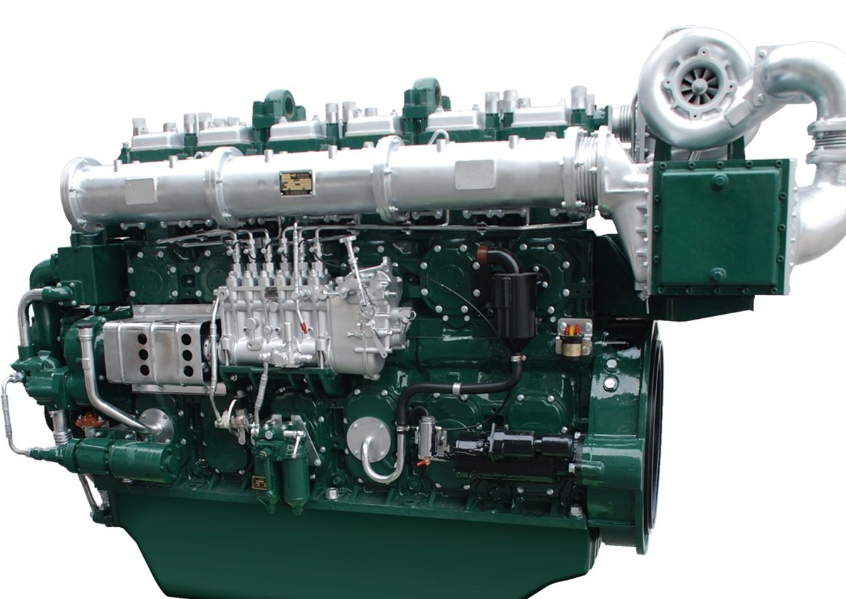

Methanol fuel direction, in July, the domestic methanol fuel engine independently developed by Hechai Heavy Industry Company of China Shipbuilding Group was successfully ignited for the first time, and it is expected that the first domestic methanol dual-fuel low-speed machine product will be launched in 2025.

Behind the different technological paths is the same concept of green development. "Green ships, that is, ships that use advanced technologies or new and clean energy to reduce pollution and greenhouse gas emissions." The relevant person in charge of the water transport Bureau of the Ministry of Transport introduced that the main characteristics of green ships are environment-friendly, and the pollutants produced by ships are less or can be effectively disposed of; The second is energy-saving and efficient, the ship's energy efficiency level is higher, and the operation is more energy-saving; The third is advanced technology, usually using technical means or clean energy to enhance the green level of ships.

As the world's first shipbuilding country, in recent years, China's shipbuilding industry closely follows the trend of green and low-carbon development, new energy and clean energy ships have developed rapidly, and the proportion of green ships has steadily increased.

Looking at the growth trend, the current delivery of new ships in China, the use of new energy clean energy ships accounted for 15.6%, and the proportion of new orders reached about 50%. With the implementation of various international emission reduction measures, the proportion of the two will continue to expand.

Looking at specific fields, LNG powered ships have been widely used, and methanol-powered ships have entered the application stage of real ships; Lithium battery powered ships are in the initial stage of development. In addition, in the past three years, the proportion of hydrodynamic energy-saving devices has reached 68.8%, and the key technical equipment has been independently controllable.

Promote energy conservation and emission reduction in maritime transport

Promote the upgrading of ships

Why are shipbuilding and shipping companies turning their attention to green power?

On the one hand, the greening of ships will strongly promote the emission reduction of shipping.

"At present, more than 80 percent of global trade is completed by sea, and green and low-carbon has become an inevitable trend in the development of the ship shipping industry." The relevant person in charge of the Maritime Bureau of the Ministry of Transport said that in July this year, the International Maritime Organization adopted a new greenhouse gas emission reduction strategy for ships, putting forward the vision of realizing net zero greenhouse gas emissions from international shipping by 2050. The use of green alternative fuels is an important path to achieve emission reduction.

On the other hand, the greening of ships will also effectively promote the upgrading of passenger and freight ships.

"As an important carrier for passengers and freight, the development of green ships has played a key role in accelerating the elimination and transformation of old ships, promoting the construction of green supporting facilities in ports, and promoting the upgrading of water transport facilities standards." The person in charge of the water transport bureau of the Ministry of Transport said.

Take the "Three Gorges Hydrogen Boat 1", which completed its maiden voyage not long ago, as an example, the ship is a steel-aluminum composite structure, with a passenger quota of 80 people, mainly using hydrogen fuel cell power system, rated output power of 500 kW, the maximum speed of 28 km/h, the cruising speed of 20 km/h, and the cruising range of up to 200 km. It is estimated that compared with traditional oil-powered ships, the "Three Gorges Hydrogen Boat 1" is expected to replace 103.16 tons of fuel oil per year and reduce carbon dioxide emissions by 343.67 tons.

"Three Gorges Hydrogen Boat 1" energy supply station is located in the Three Gorges project downstream Yangjiwan dock "China Three Gorges green electric green hydrogen demonstration station", which is the first inland dock type hydrogen hydrogenation integrated station, the use of Three Gorges power station issued by the clean electric energy electrolytic water hydrogen production, hydrogen through compression, storage, refueling and other links, directly supply hydrogen energy ships.

"Water transport itself has the comparative advantages of large transport capacity, less pollution, low energy consumption, green and low-carbon aspects. As the main transport equipment in the water transport industry, the improvement of its green level will further highlight this advantage." The person in charge of the water transport bureau of the Ministry of Transport said.

Up to now, more than 460 LNG-powered vessels have been developed in inland rivers across the country. Shanghai, Jiangsu, Hubei and other provinces and cities have introduced relevant policies to encourage the development of electric ships. Cosco Shipping Group and other enterprises are actively carrying out the pilot of electric container ships in the power exchange mode, and methanol, hydrogen fuel cell and other power ships are also in the pilot development.

The improvement of the docking shore power system has enabled more ships to use green energy. In the first half of the year, the use of shore power in ports and water service areas in 11 provinces and cities of the Yangtze River Economic Belt exceeded 50 million KWH. Since 2021, nearly 13,000 ships have been renovated, including cruise ships, commercial vehicle ro-ro ships and container ships, which have achieved full coverage of electric facilities.

"As a major shipping country in the world, China should seize the key window period from 2020 to 2030 to accelerate the breakthrough of the core technology of green ships, accelerate the development of maritime power, and lay a good foundation for the industrialization of green ships." The person in charge of the Maritime Bureau of the Ministry of Transport said.

Support the development of relevant technologies

Build a green transportation system

Benefiting from the increasingly perfect legal system and the continuous progress of construction technology, China's green ships have entered the rapid development channel in recent years. However, overall, the current scale of green ships is still small, and there is still a long way to go to fully market-oriented, large-scale and industrialization.

"The high cost of construction and operation is one reason." The person in charge of the water transport Bureau of the Ministry of Transport said that from the research situation, the construction cost of green ships is much higher than that of fuel oil ships. For example, LNG-powered ships cost nearly 40% more than new diesel-powered ships of the same tonnage. And affected by market fluctuations, LNG prices are higher than fuel oil, to a certain extent, dampened the enthusiasm of shipowners.

"Some green ship technologies are not mature in general." The relevant person in charge of the Maritime Administration of the Ministry of Transport said that some green ship technologies are not mature on the whole, such as ammonia fuel ships with good application prospects, but ammonia fuel engines are still in the research and development test period. In addition, global shipping needs coordinated development, long service life of ships and other factors, the choice and replacement of green fuel still need a long time.

However, whether it is to promote the high-quality development of the water transport industry or accelerate the construction of a green transportation system, green and low-carbon has become an inevitable trend in the development of the ship shipping industry.

"In the next step, we should speed up the improvement of technical standards for the development of green ships, carry out demonstration applications and commercial promotion, and actively strive for relevant fiscal and tax preferential policies to support and guide shipping enterprises to accelerate the construction and transformation of green ships." The relevant person in charge of the Maritime Bureau of the Ministry of Transport said that at the same time, increase the key technology and equipment research of green ships, improve the relevant service supporting facilities, and provide efficient and convenient operation services for green ships, so as to better seize the international competitive advantage of green ships and accelerate the development of China's maritime power.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands