Bently 990 vibration transmitter

Bently 990 vibration transmitter

Product Overview

Core functions and applications

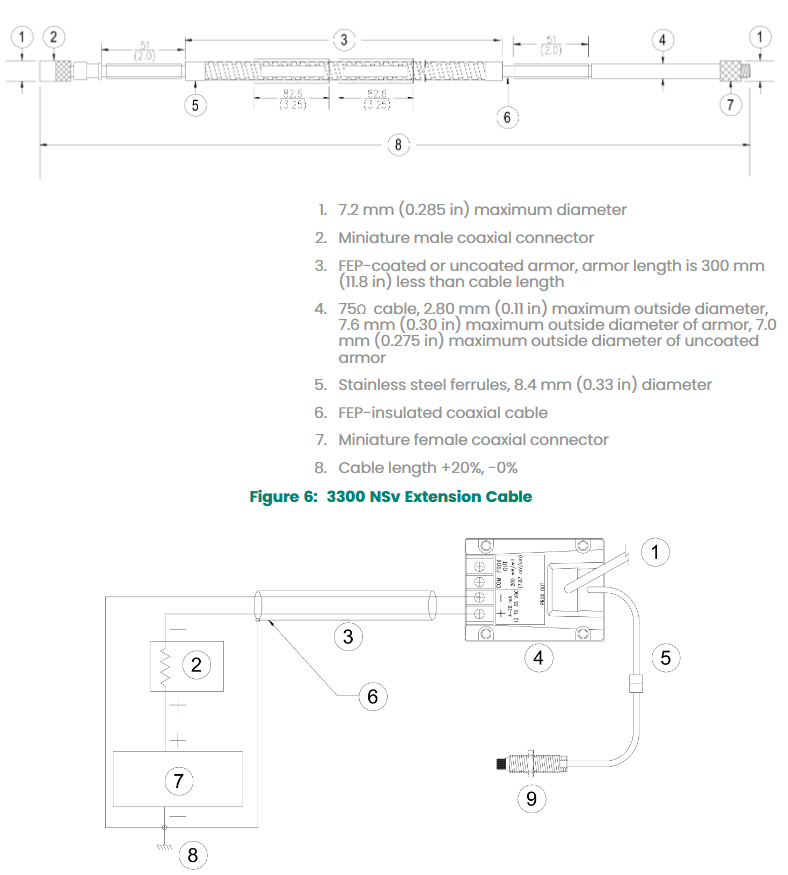

The 990 vibration transmitter is mainly aimed at original equipment manufacturers (OEMs) of centrifugal air compressors, small pumps, motors, or fans. It is used to convert vibration signals into 4-20 mA standard signals and input them into mechanical control systems. It receives input from 3300 NSv proximity probes and supporting extension cables (supporting 5-meter and 7-meter system lengths), processes the signal into engineering units of peak to peak vibration amplitude, and outputs a proportional 4-20 mA signal for mechanical protection alarm and logic control.

Main features

Integrated Proximitor sensor, no external unit required.

Provide non isolated "PROX OUT" and "COM" terminals and coaxial connectors to output dynamic vibration and gap voltage signals for diagnosis (requiring signal isolation with 990/991 test adapters).

Equipped with non interactive zero and range potentiometers, supporting circuit adjustment; The test input pin can quickly verify the circuit signal output through a function generator.

Equipped with a "Not OK/Signal Defeat" circuit to prevent high output or false alarms caused by probe failure or loose connections.

Supports DIN rail installation or through board installation (including standard accessories), suitable for high humidity (up to 100% condensation) environments.

Technical specifications

1. Electrical parameters

Startup suppression: After the power is turned on, the signal output remains in the<3.6 mA (NOT OK) state for 2-3 seconds, indicating that the device is not ready.

Proximitor sensor output: compatible with non grounded portable testing equipment; When using grounded AC power supply equipment, signal isolation must be achieved through the 122115-01 test adapter.

Output impedance: Prox Out is 10 k Ω, calibrated load is 10 M Ω.

Prox Out linear range: 1.4 mm (55 miles), starting at a distance of approximately 0.25 mm (10 miles) from the target surface.

Prox Out incremental scaling factor: 7.87 mV/µ m (200 mV/mil) ± 6.5% (typical value, including interchangeability error), worst-case scenario ± 10%; Typical noise level is 50 mV/pp.

Temperature stability: Within the range of 0 ° C to+70 ° C (+32 ° F to+158 ° F), the incremental scaling factor remains within ± 10% of 7.87 mV/µ m.

Frequency response: 5 Hz to 6000 Hz+0/-3 dB.

Minimum target size: 9.5 mm (0.375 inches) diameter.

Lead length: The maximum cable distance for the Proximitor sensor output (BNC connector) is 3 meters (10 feet).

Power supply: 28 V for hazardous areas (Zone 2 or Div 2).

2. Environmental and mechanical parameters

Temperature range:

Transmitter operating temperature: -35 ° C to+85 ° C (-31 ° F to+185 ° F); Storage temperature: -52 ° C to+100 ° C (-62 ° F to+212 ° F).

Probe operating and storage temperature: -52 ° C to+177 ° C (-62 ° F to+351 ° F).

Relative humidity: 100% condensing (non submerged, coaxial connectors need to be protected).

Mechanical characteristics:

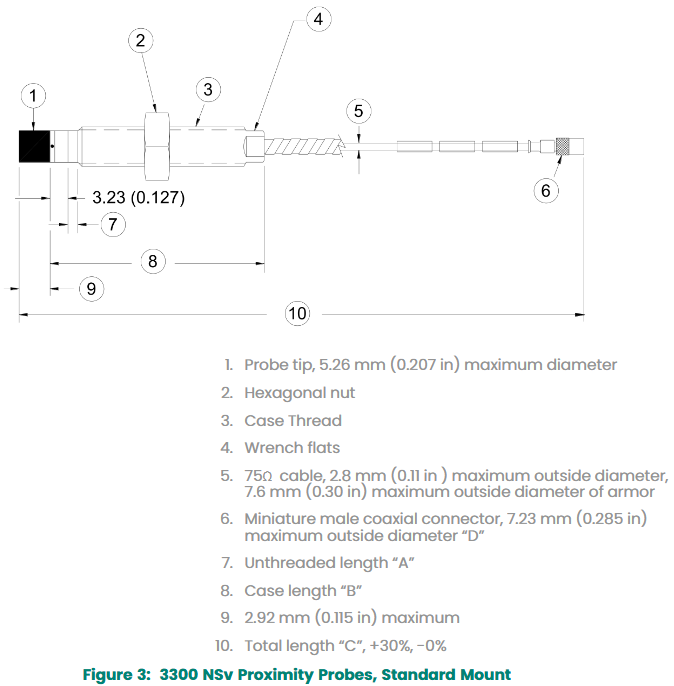

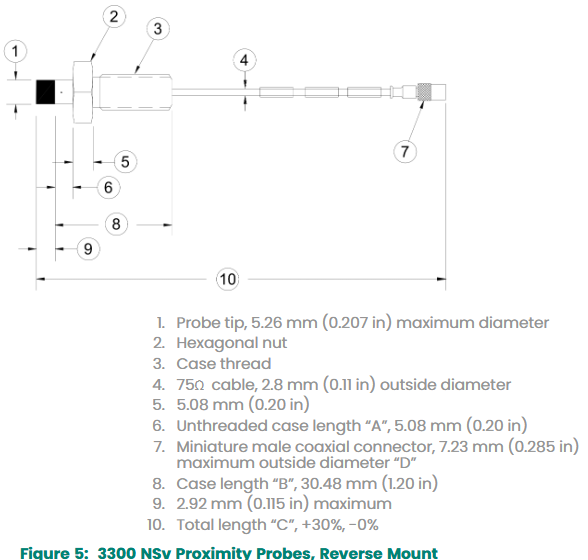

Probe tip material: Polyphenylene sulfide (PPS); Shell material: AISI 303 or 304 stainless steel.

Probe cable: 75 Ω coaxial cable, FEP insulated; Optional armor (AISI 302 stainless steel with FEP outer sheath).

Tensile strength: The maximum tensile strength from the probe housing to the lead is 222 N (50 lbf).

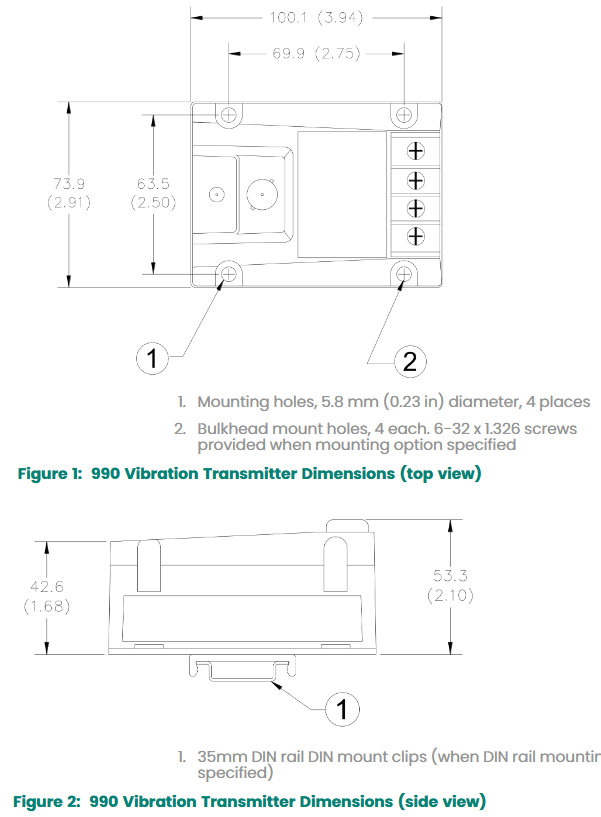

Transmitter weight: 0.43 kg (0.9 lbm); Total system weight: Typical value 0.82 kg (1.8 lbm).

Compliance and Certification

1、 Basic compliance certification

FCC certification

The device complies with Part 15 of FCC regulations and must meet two conditions for operation:

Shall not cause harmful interference;

We must accept any interference received, including interference that may cause unexpected operations.

Electromagnetic Compatibility (EMC)

Compliant with EMC Directive 2014/30/EU;

Following standards:

EN 61000-6-2 (Immunity to industrial environments);

EN 61000-6-4 (Emission limits for industrial environments).

RoHS Directive

Compliant with RoHS Directive 2011/65/EU, restricting the use of specific hazardous substances (such as lead, mercury, etc.) in electronic and electrical equipment to meet environmental requirements.

Maritime certification

Compliant with ABS 2009 Steel Ship Rules (1-1-4/7.7, 4-8-3/1.11.1, 4-9-7/13), suitable for ship and offshore platform scenarios.

EPR label for Indian batteries

Certified by GE Oil&Gas India Private Limited, EPR certificate number: 1.1595372902047E+20, in compliance with relevant regulations on electronic waste management in India.

Hazardous Area Certification

1. ATEX certification

Compliant with ATEX Directive 2014/34/EU, the specific levels are as follows:

II 1 G Ex ia IIC T4 Ga: Suitable for Zone 0/1 hazardous areas, with an ambient temperature range of -35 ° C to+85 ° C.

II 3 G Ex nA IIC T4 Gc: Suitable for Zone 2 hazardous areas with an ambient temperature range of -35 ° C to+85 ° C.

2. IECEx certification

Consistent with ATEX certification level, suitable for international explosive environments, certification mark is:

Ex ia IIC T4 Ga(Zone 0/1);

Ex nA IIC T4 Gc(Zone 2)。

3. cNRTLus certification

Suitable for hazardous areas in North America, specific level:

Class I, Div 2, Groups A、B、C、D, Temperature rating T5@Ta +85 ° C (Type 4), to be installed according to drawing 128838.

Key parameters and precautions for certification

Entity parameters (hazardous area)

Terminal/connector Ui (voltage) Ii/Io (current) Pi/Po (power) Ci/Co (capacitor) Li/Lo (inductor)

Power terminal (E1-E2) 28 V 120 mA 0.84 W 20 nF 10 μ H

Proximitor terminals (E3-E4, J2) 28 V 6 mA 0.17 W 80 nF 1 H

Probe connector (J3) 28 V 100 mA 0.8 W 27.3 nF 5.3 mH

INSTALLATION REQUIREMENTS

When used in hazardous areas, cables (type A or B) that comply with EN 60079-25 standards must be used to ensure electrical connections meet explosion-proof requirements.

Grounding and shielding must strictly follow the manual specifications to avoid interference or safety hazards.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands