ABB ACS 100 series frequency converter

ABB ACS 100 series frequency converter

Safety instructions and basic information

Safety Warning: It is emphasized that only qualified electricians can install equipment. There is dangerous voltage present, and after disconnecting the power supply, it is necessary to wait for at least 5 minutes before opening the cover. The equipment is not repairable on site, and in case of malfunction, the supplier should be contacted for replacement. It also mentioned precautions such as automatic restart, parallel power supply of control terminals, parameter modification affecting device functionality, and high temperature of heat sinks.

Installation related

Installation environment: When using the station, install at an altitude of 0-1000 meters (100% power) and 1000-2000 meters (power and current decrease by 1% for every 100 meters); The ambient temperature is 0-40 ° C (0-30 ° C at 16kHz switching frequency), and the power and current need to be reduced to 80% (4kHz switching frequency) at a maximum of 50 ° C; Relative humidity<95% (no condensation), avoid conductive dust, etc., and the installation site should be clean and dry. The storage and transportation temperature is -40-70 ° C.

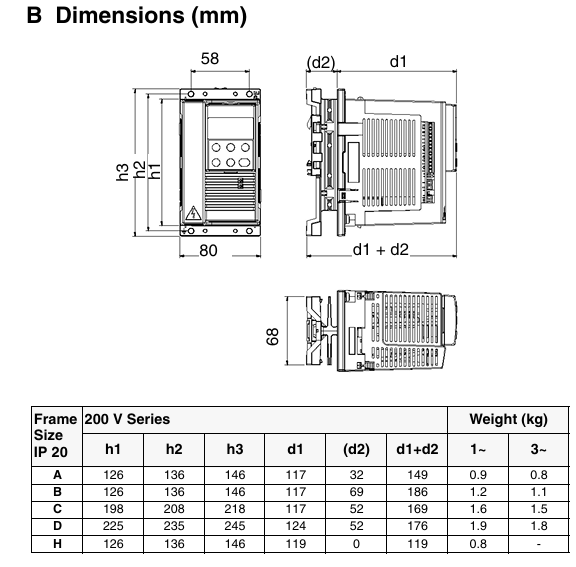

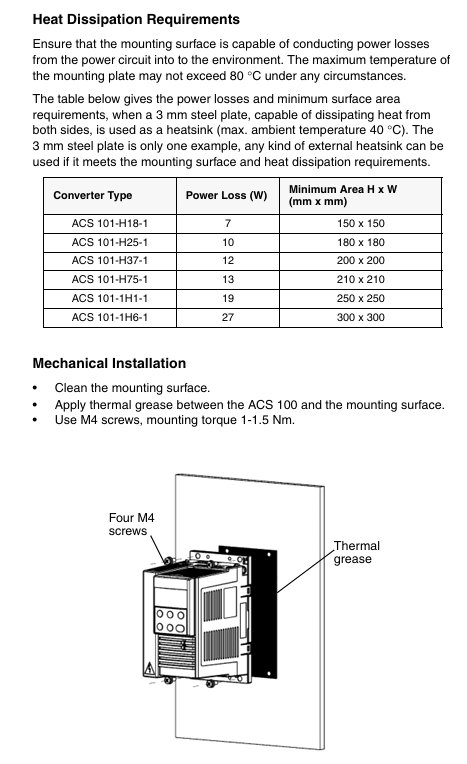

Size and installation: Frequency converters with different frame sizes (A, B, C, D, H) have different size parameters, including height, width, depth, and weight. The installation methods include wall mounting (using M4 screws), DIN rail (35mm), flange installation, etc. The frame H (without heat sink) needs to be installed on a specific metal surface and meet the heat dissipation requirements. During installation, a certain space should be ensured to facilitate heat dissipation.

Removal and installation of cover plate: Press the four snap buttons at the top and bottom corners to remove the cover plate. Before installation, reset the cover plate and then turn on the power.

Cable connection: Clearly define the connection requirements for power input, motor output, DC bus, protective grounding and other terminals. Motor cables need to be shielded and routed separately from control and power cables to avoid electromagnetic interference. Follow local cable cross-section standards, and control and power terminals have different wire diameters and torque requirements.

Terminal interface and warning stickers: Terminal interfaces include power, control, communication, and other terminals, and warning stickers in the corresponding language should be pasted at designated locations.

Technical parameters and protection functions

Technical parameters: divided into standard series and non heat sink series. Different power inverters have detailed parameters in terms of input voltage, continuous output current, maximum output current, switching frequency, protection limits (overcurrent, overvoltage, etc.), maximum length of motor cables, terminal wire diameter, fuses, power loss, etc.

Protection function: It has overcurrent, overvoltage, undervoltage, overheating, output ground fault, output short circuit, input phase loss, power loss tolerance (500ms), I/O terminal short circuit protection, long-term overcurrent limit trip (110%), short-term current limit (150%), motor overload protection, etc. The LED indicator light will display the corresponding alarm and fault status.

Programming and Operations

Control Panel (ACS 100-PAN): Can be connected and removed at any time, supports parameter copying to other ACS 100 of the same software version, has local (LOC) and remote (REM) control modes, can display output frequency, current, etc., and can be started/stopped, direction switching, parameter setting and other operations through buttons.

Configuration switch (S1): Used to configure the I/O configuration of motor rated frequency, acceleration/deceleration ramp time, and digital input. Position 0 is the default, and if using the control panel, it needs to be set to 0. Its position is read when the power is turned on.

Parameter settings: Contains multiple parameter groups, involving actual values and states, motor values and limits, drive control, input/output, monitoring, etc. Some parameter modifications are limited by startup status and configuration switch positions, and can be viewed and set through the control panel.

Menu function: It can restore factory default settings, copy parameters between the panel and the drive, etc. It needs to be operated when the drive is stopped and the local control, configuration switch is set to 0, and parameter lock is released.

Diagnosis and fault handling

Alarm and fault codes: List the codes and descriptions of various alarms (such as parameter upload/download failure, operation not allowed during startup activation, etc.) and faults (such as overcurrent, DC overvoltage, etc.). Alarm and fault information can be cleared through the control panel buttons, and some faults require power-off reset.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands