ABB ACH 400 AC Drive

ABB ACH 400 AC Drive

Safety instructions and basic information

Safety Warning: It is emphasized that equipment installation must be operated by qualified electricians. There is dangerous voltage present, and after disconnecting the power supply, it is necessary to wait for at least 5 minutes before opening the cover. The equipment is not repairable on site, and in case of malfunction, the factory or authorized service center should be contacted for replacement. Also mentioned are precautions such as automatic restart, parallel power supply of control terminals, and high temperature of heat sinks.

Installation related

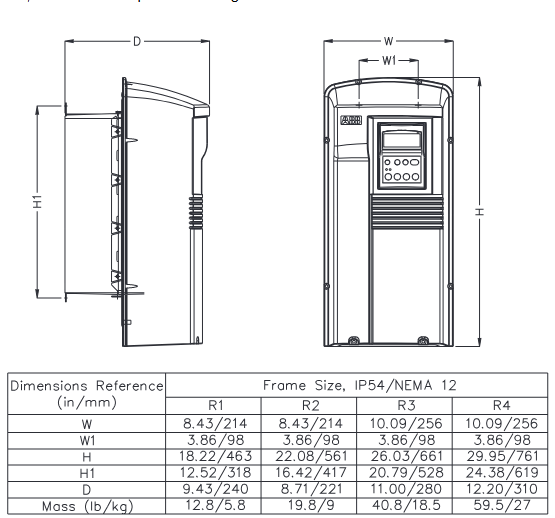

Preparation before installation: Tools such as screwdrivers and wire strippers should be prepared to record the power supply voltage, rated current, and other data on the motor nameplate. After unboxing, it includes a user manual, conduit box, warning stickers, and installation guide. The packaging box cover has a wall mounted template.

Installation environment: When using the station, the ambient temperature is 0-40 ° C (if the temperature reaches 50 ° C, the rated power and current need to be reduced to 90%), the installation altitude is 0-1000 meters (100% power), 1000-2000 meters (1% reduction per 100 meters), and the relative humidity is less than 95% (no condensation). It needs to be installed indoors in a controlled environment, with protection levels of IP21/NEMA Type 1 and IP54/NEMA Type 12, and IP54 protection against dust and light water spray. The storage and transportation temperature is -40-70 ° C.

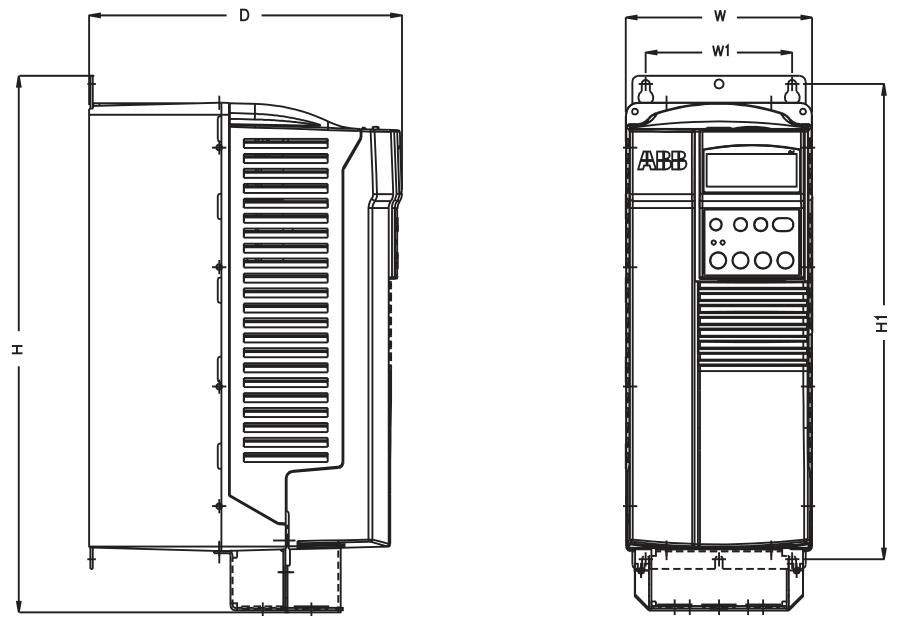

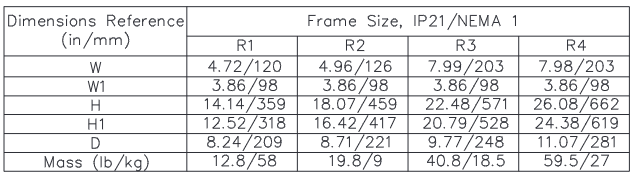

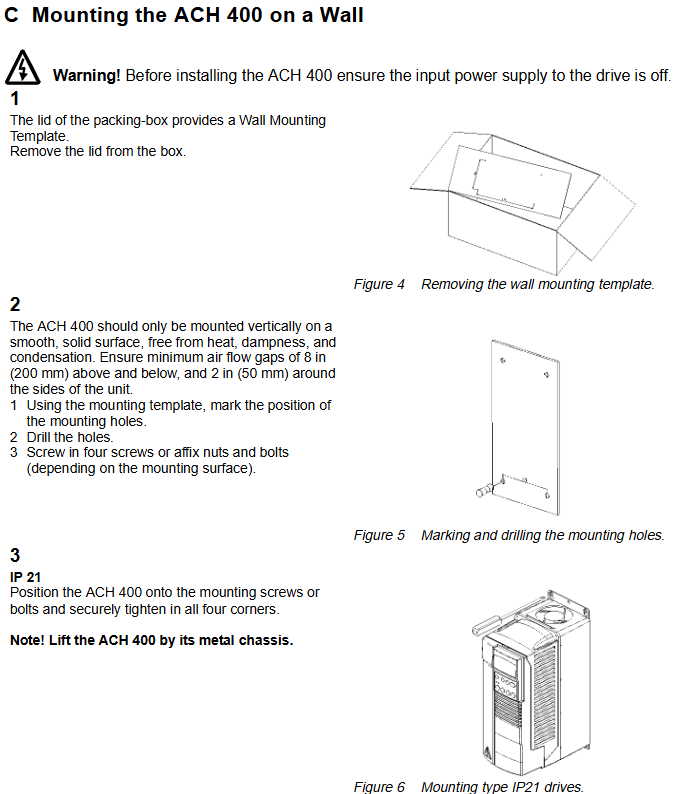

Size and Installation: Drivers with different protection levels and frame sizes have different sizes. The width, height, depth, and quality parameters of each frame size (R1-R4) for IP21/NEMA Type 1 and IP54/NEMA Type 12&4 are clearly defined. The installation needs to be vertically fixed on a smooth and sturdy surface, ensuring an air flow gap of 8 inches up and down, and 2 inches around. It should be fixed by drilling holes according to the template. For the IP54 model, the front cover and rubber plug need to be removed first.

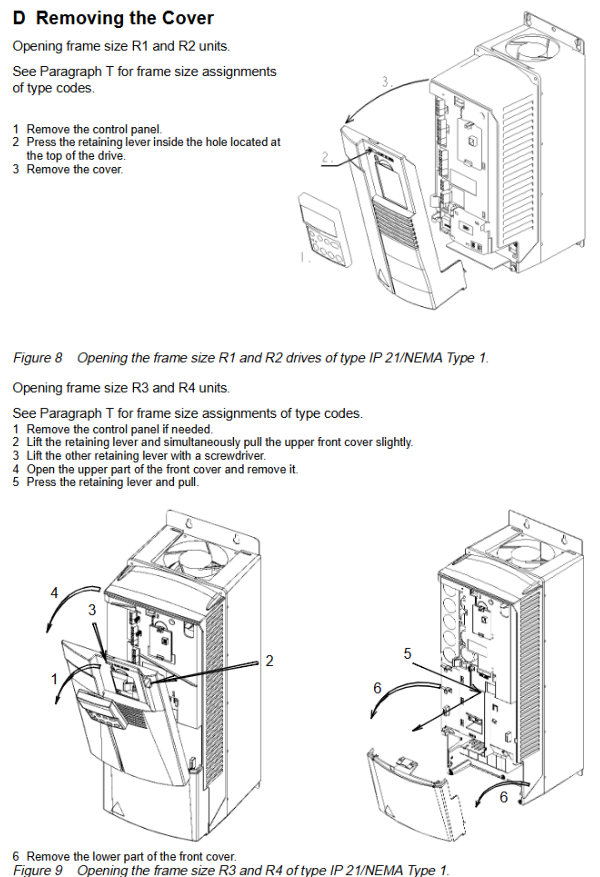

Dismantling and installation of cover plate: The steps for disassembling and installing cover plate are different for drivers with different frame sizes and protection levels. The IP21 and IP54 models of R1, R2, R3, and R4 have their own operating points.

Terminal interface and warning stickers: Terminal interfaces include power, control, communication, and jumper terminals, and warning stickers need to be pasted at designated locations.

Cable connection: Clearly define the connection requirements for each terminal (power input, motor output, DC bus, control wiring, etc.), follow local cable specifications and standards, separate different types of wiring, use shielded cables for control wiring, specific temperature levels for power cables, and mention relevant content on motor protection.

Technical parameters and protection functions

Technical parameters: The rated motor power (square torque and constant torque), input-output current, maximum output current, switching frequency, protection limits (overcurrent, overvoltage, etc.), maximum terminal diameter and screw torque, line fuse and other parameters for different frame sizes are listed in detail, with inputs of 208-240V and 380-480V.

Protection function: It has multiple protection functions such as overcurrent, overvoltage, undervoltage, overheating, output grounding fault, output short circuit, input phase loss, I/O terminal short circuit protection, motor overload protection, output overload protection, locked rotor protection, underload, etc. The LED indicator light will display the corresponding alarm and fault status.

Programming and Operations

Control Panel (ACS-PAN-B): It is an alphanumeric panel with backlit LCD, which can be connected and removed, supports parameter copying, has manual, automatic, stop and other control modes, displays output frequency and other information, and can adjust display contrast.

Menu structure and parameter settings: Contains multiple parameter groups, with basic parameters initially visible, and the full parameter set can be selected through the menu function. Setting parameter values requires entering the setting mode, where default values can be viewed.

Application macros: preset parameter sets, including HVAC Hand Auto, HVAC Floating Point, HVAC PID Control, HVAC PFC Control, etc. After selection, all parameters except for specific parameters will be set as default values. Different macros have different input and output signals and parameter values.

Diagnosis and fault handling

Alarm and fault codes: List the codes, messages, and descriptions of various alarms (such as operation failure, startup activation, etc.) and faults (such as overcurrent, DC overvoltage, etc.). Faults can be reset through the control panel, and some require power-off reset.

Diagnostic counters: Diagnostic counters related to Modbus communication, such as error messages, good messages, etc., can be used to debug fieldbus systems and can be reset through control panel or serial communication.

Communication function

Standard Serial Communication: Supports Modbus protocol and can be connected to external control systems. There are two serial communication channels, Channel 1 is a Modbus fieldbus connection and requires activation of relevant parameters.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor