ABB Distributed Control System (DCS)

Function: Control, automate, and coordinate almost all aspects of production to help optimize productivity, ensure quality, and improve sustainability. It can remotely realize the automation operation of industrial equipment such as motors, valves, pumps, etc., ensuring their safe and efficient operation. It is widely used in industries such as chemical and mining, such as safe conversion of raw materials in the chemical industry, mining, transportation, and other links.

ABB Distributed Control System (DCS)

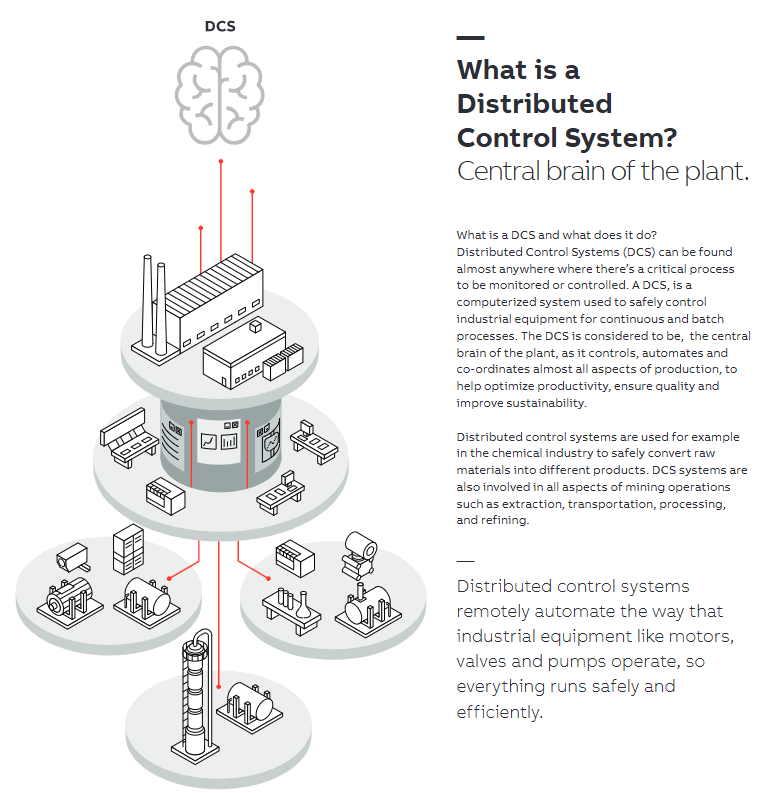

Definition and functions of DCS

Definition: Distributed Control System (DCS) is a computerized system used for safe control of industrial equipment in continuous and batch processes, and is considered the "central brain" of a factory.

Function: Control, automate, and coordinate almost all aspects of production to help optimize productivity, ensure quality, and improve sustainability. It can remotely realize the automation operation of industrial equipment such as motors, valves, pumps, etc., ensuring their safe and efficient operation. It is widely used in industries such as chemical and mining, such as safe conversion of raw materials in the chemical industry, mining, transportation, and other links.

The core capabilities of ABB distributed control system

Safe and reliable: Ensure high production availability and output while protecting personnel safety and the environment.

Efficient and high-yield: As the core of factory level digitization, it improves asset utilization, process efficiency, and product quality.

Precise and sustainable: By strictly controlling factory energy and raw material consumption, the environmental impact is significantly reduced.

Process factory challenges addressed by DCS

Utilizing industrial grade computers known as process controllers to achieve remote automation control of industrial equipment. These controllers are functionally and physically distributed, used to supervise and control various parts of the process (referred to as units).

Analog and digital input/output modules, as well as fieldbus technology, transmit information between process controllers and various field devices. On site devices such as transmitters, actuators, and drivers are used to measure and control the temperature, liquid level, pressure, and flow rate of various materials used in industrial processes.

Safety specifications are generally applicable to control system handling. Instructions and warnings related to a specific subject or operation of the product.

The following norms must be strictly observed:

must strictly comply with the technical specifications and typical applications of the product system

Personnel training: Only trained personnel shall install, operate, maintain or repair the product system. must

Provide guidance and explanation of the situation in danger areas to these personnel.

Unauthorized changes: Changes or structural changes to the product system may not be made.

Maintenance responsibility: Must ensure that the product system is used only under appropriate conditions and in full fitness for use.

Working environment: The user must meet the specified environmental conditions:

Safety regulation

The following safety provisions of EN 50110-1 shall be fully complied with when handling product systems (maintenance) :

1 Disconnect completely.

2 Secure to prevent reconnection.

3 Verify that the installation is complete.

4 Ground and short-circuit the device.

Warning: Only qualified maintenance personnel can remove and insert the module. In order to ensure the personal safety of the operator, before each pulling out or inserting, you must

Disconnect the power supply and ensure that there is no voltage on all terminals at the back, and the product is effectively grounded with the ground screw at the back.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands