EMERSON CSI 2130 Machinery Health ™ Analyzer

EMERSON CSI 2130 Machinery Health ™ Analyzer

Overview

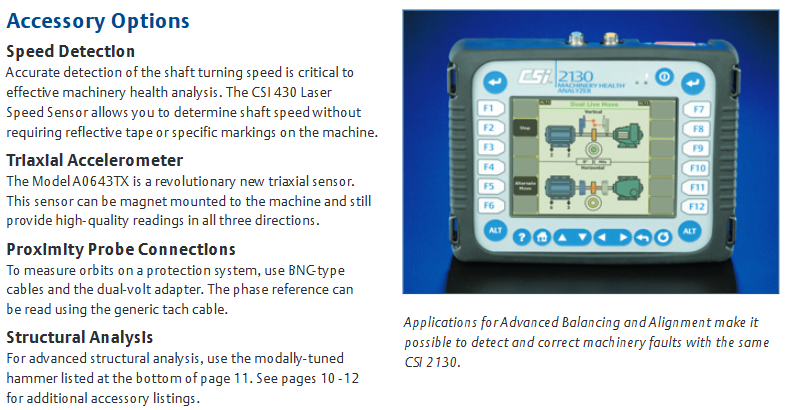

The CSI 2130 Machinery Health Analyzer is a device that integrates data collection, vibration analysis, alignment, and balancing functions, designed specifically to meet the efficient work needs of maintenance departments with reduced personnel and budget. It is easy to operate, can quickly and accurately identify potential equipment failures and identify the root cause, and can also upload data to AMS Suite to provide a unified view of the health status of factory equipment, helping to improve factory availability and reliability.

Core advantages

Efficient data collection: Compared with the previous generation product CSI 2120, the data collection time is reduced by up to 60%. The dual channel option can additionally reduce measurement time by 20% -45% through patented data collection technology, enabling monitoring of more machines and improving work efficiency.

Portable and durable

Equipped with a large color backlit VGA display screen, suitable for various environments.

Small in size and lightweight (4.5 lbs), making it easy to carry over long distances.

Featuring IP 65 protection level and optional security certification, suitable for use in industrial environments.

Easy to operate: With minimal training, it can effectively operate and convert data into actionable equipment health information, such as automatically distinguishing between unbalance and bearing faults, allowing users to immediately focus on critical machine issues.

Embedded intelligence: Even novice users can perform complex diagnostic tests through simple operations, fully utilizing the device's role on site.

Key functions

Fault detection capability

Using patented PeakVue ® Processing technology can detect stress waves, detect signs of bearing and gear wear at the earliest, provide indications of fault severity, and convert them into reliable trends to determine the optimal maintenance time.

With an excellent frequency range, the patented low-speed technology (SST) can accurately measure low-speed equipment signals, up to 80000 Hz, suitable for high-speed mechanical diagnosis.

On site analysis tools: including waveform autocorrelation, fault frequency superposition, narrowband parameter trend analysis, 14 predefined analysis experts, four quadrant plotting, etc., to assist in in-depth analysis of equipment problems.

Variable speed analysis: During the routine data collection process, all diagnostic tools can be automatically adjusted to adapt to changes in equipment speed and accurately assess potential issues on site.

Predicting catastrophic failures: By collecting signals from online monitoring systems, generating track maps to identify issues such as misalignment and shaft friction, trend data can help detect structural failures.

Monitoring fault points: With the help of line power supply, it can be used as a temporary online monitor to monitor the health status of equipment for a long time, automatically obtaining and storing data.

Capture machine shutdown status: For transient event analysis, a series of vibration snapshots can be collected during equipment startup, shutdown, or process changes, which can be viewed separately or in a waterfall chart.

Linking vibration and process variables: Using dual channel functionality, process information is input as a voltage signal into one channel, while vibration is monitored in the other channel to identify machine problems.

Multi functional configuration

Modular design: It can be configured according to current requirements, and can easily expand functions as requirements change, protecting initial investment. It can be used as a single channel or dual channel analyzer, dedicated field balancer, or laser alignment calculator, and can also add modules for transient and structural analysis.

Advanced cross channel analysis: Standard data collection is a good foundation for identifying equipment failures, and cross channel analysis helps identify the root cause of the failure. Dual channel devices can display tracks, optional advanced cross channel applications can expand functionality, ODS/modal applications make structural analysis simpler, and cross channel data can be analyzed or exported in relevant software.

Advanced transient analysis: expands the functionality of single channel or dual channel devices, allowing for long-term recording of raw vibration signals for post-processing and analysis. It is suitable for diagnosis of turbomachinery, start-up and shutdown, or machines with short repetitive work cycles. The data can be checked on the device or in related software.

On site balancing: Advanced balancing applications make devices powerful on-site balancers, with a graphical user interface guiding operations, basic and advanced modes, special features such as vector averaging and balance monitoring, and the ability to print or store job documents.

Laser alignment: Advanced laser alignment applications provide a graphical driven user interface and wireless operation, with built-in dual inclinometers to automatically determine axis position, real-time movement options, and job documentation available in relevant software.

Motor current analysis: with MotorView in AMS Machinery Manager ® Module coordination, using standard current clamps or patented magnetic flux monitoring, for non-invasive analysis of the rotor and stator condition of induction motors.

Specification parameters

Physical data: The color display screen is a 5.75 "x 4.25" transflexible LCD screen with backlight and a resolution of 640 x 480 pixels; The keyboard has large easy to press keys, 12 soft function keys, and context sensitive help keys; The dimensions are 8 "high x 1.88" deep x 10.25 "wide; Weight 4.5 lbs.

Operating conditions: Sealed casing, IP-65 protection level; The working temperature ranges from 15 to 113 º F (-10 to 50 ° C).

Power supply: Nickel hydrogen battery, 4.5 ampere hours, 7.2 V; typically used for 8 hours (longer when backlight is turned off), data can be saved when battery voltage is low; Equipped with an "intelligent charger" that can discharge, quickly charge, trickle charge, and also serve as a continuous power source; Charging time is 3 hours.

Quality assurance: NIST traceable calibration; There is a safety rating version approved for use in Class I, Zone II, Groups A, B, C, and D. The performance specifications of the safety rating version are the same as those of the standard model.

Safety certification: CSI 21302Q has obtained multiple safety certifications such as FM, CSA, ATEX, etc.

Analysis and routing specifications

Analysis experts: including various interactive data acquisition settings such as high-frequency, high-resolution, and bearing/gear fault analysis.

Data analysis speed: 400 lines/1000 Hz spectrum is 0.14 seconds/average; The 1600 line/1000 Hz spectrum is 0.5 seconds/average.

Analytical ability: noise floor PeakVue、 Demodulation SST、 There are corresponding performance indicators for dual channel, cross channel, and dynamic analysis; The signal range, frequency range, low-frequency response, resolution, average, average quantity, integration, triggering, anti aliasing and other parameters are also clearly defined.

Amplitude units: metric or imperial, acceleration, velocity, displacement, or user programmable.

Frequency units: Hz, CPM, Orders.

Scaling: Both the X and Y axes are linear or logarithmic.

Window: Hanning or Uniform.

Cursors: single cursor, harmonic cursor, moving harmonic cursor, edge band cursor.

Memory: 512 MB internal storage, equipped with a secure digital memory card slot, with almost unlimited memory.

Signal input: including power input, non power input, input impedance, tachometer, pseudotachometer, three-axis, output and other parameters.

Balance specifications

Basic mode: Provides pre configured tasks for balancing single and double planes, and a full calculator mode.

Advanced mode: up to 4 planes, up to 8 sensor inputs, up to 6 different speeds, automatic unit conversion, automatic weight distribution, trial weight estimation.

Special function: Vector averaging eliminates background vibration; The balance monitor automatically detects secondary mechanical faults; The graphical user interface provides data stability indicators, displays real-time imbalance vectors, and eliminates weight placement confusion.

Align specifications

Basic modes: automatic scanning (including partial scanning), manual 4-point, soft foot detection, thermal growth compensation, real-time machine movement, Jackshaft application, recording annotations and observation results, storing and calling jobs.

Advanced mode: Quick specification alignment checker, manual scanning, two-way mode (uncoupled axis), vertical machine alignment, C-plane alignment, straightness measurement, enhanced soft foot detection, data averaging, custom machine configuration, custom tolerance values, additional real-time movement options, uploading jobs to software.

Communication: Standard measurement via cable, no cable measurement, optional RF (where allowed).

Special features: thermal growth compensation, real-time machine movement, Jackshaft application, recording annotations and observation results.

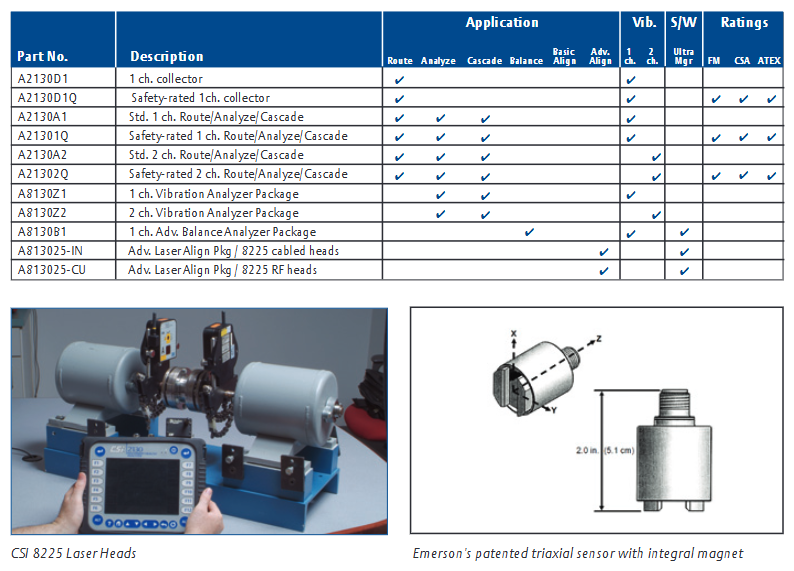

Accessories Options

Including speed detection (such as CSI 430 laser speed sensor), three-axis accelerometer, proximity probe connection, structural analysis tool, power supply, cable, housing, screen protector, various sensors, adapters, current clamps, battery packs and other accessories, can be selected according to needs.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands