ABB DCS series thyristor power converter

ABB DCS series thyristor power converter

Product core positioning and application scenarios

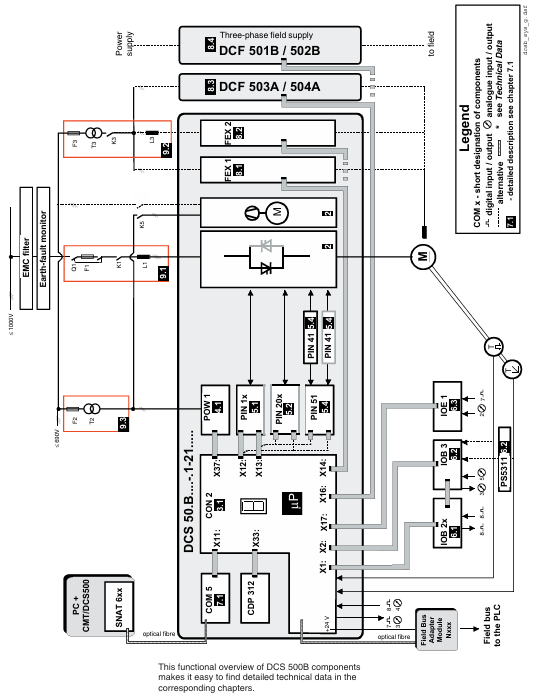

The ABB DCS series thyristor power converter is an industrial grade power conversion equipment designed specifically for DC drive systems. Its core function is to accurately convert three-phase AC power into adjustable DC power, providing stable armature and excitation power for DC motors. At the same time, it integrates complete control, protection, and communication functions to achieve precise control of motor speed and torque. Its typical applications cover medium and high voltage industrial scenarios, including:

General industrial drive: medium and high-power DC motor control in metallurgy (rolling mill), mining (hoist), papermaking (coiler), chemical (pump/fan) and other fields;

Special scenario adaptation: Supports MultiDrive, CraneDrive, 12 pulse series/parallel topology, which can meet high power (up to 5200A output current, power above 10MW) and high reliability requirements;

Upgrade and Renovation: Compatible with old DC drive systems, providing modular design for easy upgrading of existing equipment and reducing renovation costs.

Product series and core categories

The DCS series is divided into multiple sub models based on power level and functional complexity, covering different application requirements. The core classifications are as follows:

Product Model Power/Current Range Core Features Applicable Scenarios

DCS 400 10-500 kW (corresponding to motor power), integrated excitation output (up to 20A), compact design, built-in IGBT excitation module, supports quick debugging (guided configuration+application macro), compact structure for standard industrial scenarios (such as small pumps and fans), equipment with high installation space requirements

DCS 500B 10-5000 kW, Output current 25-5200A based on SDCS-CON-2 control board, supports 300+programmable function blocks, compatible with HART signals, optional 12 pulse configuration for high-power universal drives (such as compressors and rolling mill auxiliary drives), suitable for scenarios requiring flexible programming

DCS 600 10-5000 kW, Upgrade SDCS-AMC-DC control communication board with an output current of 25-5200A, supporting DDCS bus (4Mbps) and PROFIBUS-DPV1, suitable for high demand industrial scenarios with multiple drives and PLC integration (such as cranes and large fans), requiring multi device collaborative control systems

DCF 500B/600 excitation dedicated, maximum output current 520A based on DCS 500B/600 hardware, supports three-phase excitation mode, requires DCF505/506 overvoltage protection unit for DC motor excitation power supply, suitable for large synchronous motors and DC motor excitation control

DCA/DCE series 10-18000 kW (DCA 600) integrated complete control cabinet (including circuit breakers, contactors, auxiliary transformers), pre programmed industry applications (metallurgy, mining) complex system solutions (such as whole production line transmission, large mining equipment)

Core hardware and technical specifications

(1) Power module and electrical parameters

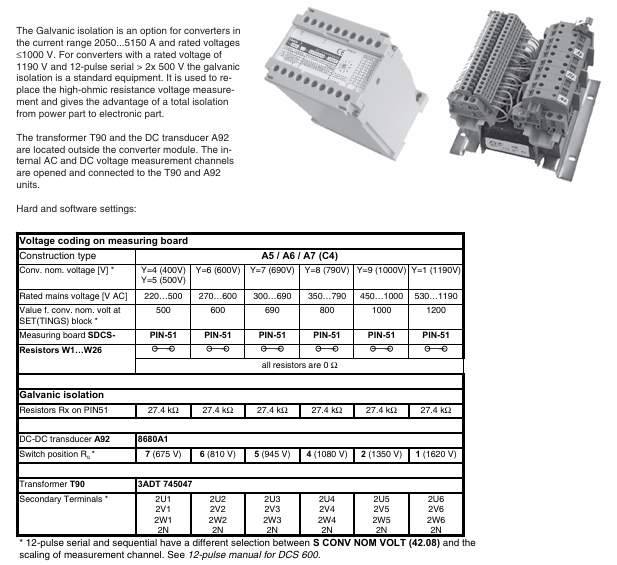

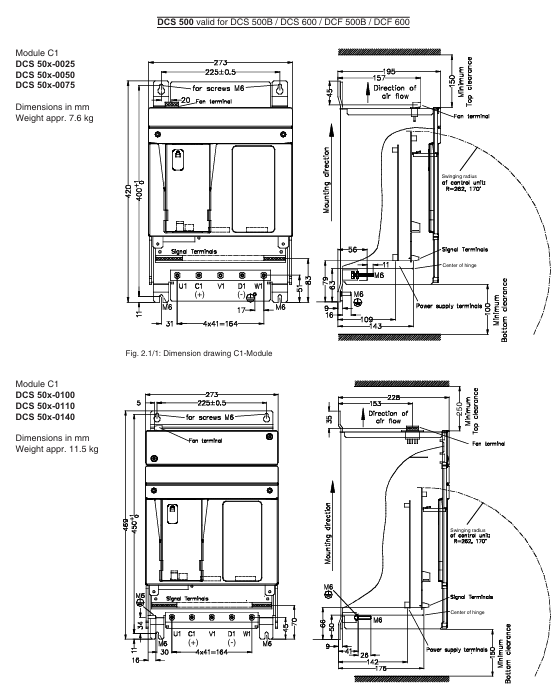

The DCS series power modules are divided into C1/C2/A5/A6/A7 sizes according to current levels, covering different output current requirements. The core parameters are as follows:

Module size, output current range, voltage level, cooling method, key configuration

C1 25-140A 400-1000V DC forced air cooling (with built-in fan) single/double bridge thyristor topology, supporting 2-quadrant (2-Q)/4-quadrant (4-Q) operation

C2 200-1000A 400-1000V DC forced air cooling with multiple parallel thyristors, supporting 12 pulse series connection, suitable for medium power motors

A5 900-2000A 400-1000V DC forced air/water cooling (optional) modular thyristor group, supporting galvanic isolation, suitable for high-voltage motors

A6/A7 2050-5200A 400-1000V DC water-cooled (standard) multi bridge parallel connection, supports redundant design, suitable for high-power scenarios (such as motors above 10MW)

Key electrical performance

Current accuracy: ± 0.5% full range (at rated current), current imbalance compensation range of 4% -30%;

Voltage range: Input AC 400-690V (50/60Hz), output DC 0-1000V (depending on the model);

Power loss: including current dependent loss (thyristor, fuse), voltage dependent loss (buffer circuit), fixed loss (electronic components, fan), typical value 10-17250W (depending on current level);

Overvoltage/over-current protection: Built in MOV (metal oxide varistor), RC buffer circuit, over-current trip time can be set (10ms-2000ms), ground fault detection supports 50:0.025A/1A/5A CT.

(2) Control and Interface Module

The DCS series core control relies on dedicated circuit boards to achieve signal acquisition, logic control, and communication interaction. The key modules are as follows:

Module Name Core Function Technical Features

SDCS-CON-2 (control board) core logic control, including 80186EM processor, ASIC circuit supporting RS485 (2 channels, used for excitation control and panel communication), DDCS bus (4Mbps), built-in watchdog, monitoring 6 voltage channels (+5V/+15V/-15V/+24V/+48V1/+48V2)

SDCS-POW-1 (power board) provides multi-level DC voltage (+5V/+15V/-15V/+24V/+48V) switch power supply design, input AC 115/230V (± 10%), power consumption 120VA, supports encoder power selection (5V/12V/24V)

SDCS-PIN series (power interface board) thyristor triggering, current/voltage measurement, hardware coding PIN-1x (C1 module), PIN-20x (C2 module), PIN-41/51 (A5/A6/A7 module), supports current transformer signal acquisition, zero current detection

SDCS-IOB series (I/O board) expands digital/analog I/O IOB-2 (8-channel isolated digital I/O), IOB-3 (5-channel analog input+3-channel analog output, supports encoder isolated input), compatible with PT100/PTC temperature sensors

SDCS-COM-5/AMC-DC (communication board) external communication extension COM-5 supports HDLC (1.5Mbps) and DDCS (4Mbps); AMC-DC supports PROFIBUS-DPV1, fiber optic communication (10Mbps), and is compatible with multi drive collaboration

Core functions and technological advantages

(1) Precise control and adjustment

Excitation control:

Built in excitation module (SDCS-FEX-1/2, output 6-16A) or external excitation unit (DCF503A/504A, output 50A), supports separate/parallel excitation motors, and is compatible with weak magnetic speed regulation;

Excitation current closed-loop control, with an accuracy of ± 1%, supports excitation fault detection (such as demagnetization protection), and is equipped with DCF505/506 overvoltage protection to prevent excitation winding overvoltage damage.

Speed and torque control:

Support PID speed regulation (proportional gain, programmable integration time), speed accuracy ± 0.1% (with encoder feedback);

Torque and current limiting functions to prevent motor overload and adapt to load fluctuation scenarios (such as crane lifting).

Multi quadrant operation:

The 4-quadrant module (such as DCS 500B-4Q) supports motor forward and reverse rotation, power generation braking, and is suitable for scenarios that require energy feedback (such as elevators, lowering loads).

(2) Comprehensive protection mechanism

Protection type, specific functions, technical details

Thermal overload protection is based on dynamic calculation of motor thermal capacity (TCU), considering negative sequence current bias (additional rotor heating) and RTD temperature bias (stator/bearing temperature correction), supporting 15 standard overload curves and custom FlexCurve ™

Electrical fault protection short circuit, grounding, undervoltage/overvoltage, phase sequence reversal short circuit tripping time 10ms-2000ms, grounding fault detection sensitivity 0.25-25A, phase sequence reversal protection response time ≤ 100ms

Mechanical fault protection for locked rotor, bearing high temperature, and anti rotation detection. The locked rotor protection is based on current threshold (2-10 × FLC), RTD monitors bearing temperature (-40-200 ℃), and anti rotation detection (option B) is suitable for underground pumps to prevent damage caused by reverse restart

Disable thyristor triggering when the system protection watchdog, power monitoring, and EMC protection watchdog are triggered; Power undervoltage (such as+5V below 4.55V) triggers hardware reset; Supports EN 61000-6-2/4 EMC standard, optional NF3/NF1 series EMC filters

(3) Data Collection and Communication

Status monitoring:

Real time collection of parameters such as current, voltage, power, temperature (RTD), speed, etc., with an accuracy of ± 1% - ± 2%;

Event records (512 records, including reasons for tripping, current/voltage waveforms), startup data recorder (recording 30 second startup process), supporting fault tracing.

Communication ability:

Supports Modbus RTU/TCP, PROFIBUS-DPV1, DeviceNet, DDCS fiber optic bus, and can be connected to PLC (such as ABB AC800M) and SCADA systems;

Multi drive communication (DDCS bus, 4Mbps) supports master-slave control (such as multi motor synchronization), and fiber optic communication distance can reach 200 meters (HCS fiber optic cable).

Installation and Accessories

(1) Installation configuration

Module installation: C1/C2 modules are installed using DIN rails or 19 inch racks, while A5/A6/A7 modules require independent cabinet installation (supporting water-cooled pipe connections);

Wiring requirements: Power cables (copper bars/cables) with a cross-sectional area of 2.5-100mm ² (depending on current level), control cables need to be shielded (EMI resistant), encoder cables support differential signals (up to 150 meters long);

Environmental adaptation: Working temperature 0-50 ℃ (air-cooled), 0-40 ℃ (water-cooled), relative humidity 95% (non condensing), protection level IP20 (module)/IP54 (control cabinet).

(2) Key accessories

Accessory type, model/specification, and purpose

EMC filters NF3 series (three-phase, 25-2500A) and NF1 series (single-phase, 8-55A) suppress conducted interference, meet the EN 50081 standard, and are suitable for public grid access

The ND series of incoming reactors (ND01-ND16, inductance 50-512 μ H) reduces grid harmonics, improves power factor (cos π≥ 0.9), and protects thyristors

Residual current detection for current transformers PWS 10004 (1500A) and PWS 33001 (3300A), compatible with ground fault protection

Cooling accessories fan (CN52B2, W2E143), water-cooled radiator to ensure module heat dissipation, A7 module water-cooled flow rate ≥ 5L/min (Δ T ≤ 30 ℃)

Programming tool DriveWindow software, CDP312 panel parameter configuration, fault diagnosis, real-time monitoring, supports offline programming and online debugging

Model selection and ordering information

(1) Model coding rules

Taking "DCS 500B-0250-51-4Q" as an example, the key parameter meanings are:

500B ": Basic model;

0250 ": Output current 250A;

51 ": Voltage level 500V DC;

4Q ": Running in 4 quadrants.

(2) Core selection criteria

Motor parameters: Select the module based on the rated power of the DC motor, armature voltage/current, and excitation voltage/current (e.g. 100kW/440V motor compatible with DCS 500B-0250-51);

Application requirements: Select 4-quadrant module for energy feedback, DCS 600+AMC-DC communication board for multi motor synchronization, and water-cooled module for high temperature environment;

Power grid conditions: The public power grid needs to be equipped with EMC filters, and if the power grid harmonics are severe, line reactors need to be added.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA