Schneider Electric Foxboro ™ DCS FBM201/b/c/d analog input module

Schneider Electric Foxboro ™ DCS FBM201/b/c/d analog input module

Product core positioning and application scenarios

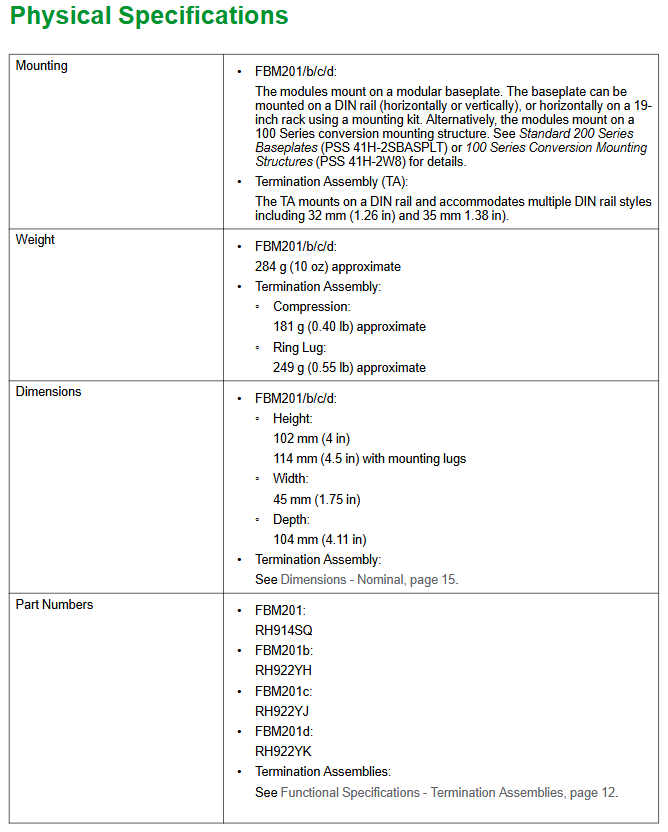

FBM201/b/c/d is Schneider Electric EcoStruxure Foxboro ™ The core function of the analog input module in distributed control systems (DCS) is to accurately convert the analog signals (current, voltage, millivolt level signals) output by industrial field sensors (such as pressure, temperature, flow sensors) into digital signals, which are transmitted to DCS controllers (such as Field Control Processor, FCP) to achieve real-time acquisition and monitoring of process parameters. Its typical application scenarios cover process industries such as petrochemicals, power, water treatment, and manufacturing, and are suitable for industrial control scenarios that require high accuracy of analog signals and complex environmental conditions (such as Harsh level harsh environments).

Product Model and Core Classification

The FBM201 series includes 4 sub models, with the core difference being the supported analog input signal range, which can be flexibly selected according to the type of sensor on site:

Model input signal range key adaptive sensor

FBM201 0-20 mA DC (compatible with 4-20 mA industrial standard signal) 4-20 mA two-wire/four wire transmitter (such as pressure transmitter, liquid level transmitter)

FBM201b 0-100 mV DC millivolt level signal sensor (such as strain gauges, thermocouple signal conditioning output)

FBM201c 0-5 V DC 0-5 V voltage output sensor (such as some temperature sensors, concentration sensors)

FBM201d 0-10V DC 0-10V voltage output sensor (such as high-precision flow sensor, displacement sensor)

Core technical specifications and performance parameters

(1) Input channel and signal conversion

Category specific parameter description

Number of channels: 8 independent channels. Each channel can be separately connected to different types of sensors (matching corresponding module models), and the channels do not interfere with each other

Isolation design between channels and between channels and ground: Galvanically isolated. The isolation voltage reaches 600 VAC (1-minute withstand), effectively suppressing electromagnetic interference (EMI) in industrial sites and preventing signal crosstalk and grounding loop problems

The signal conversion is independent for each channel. The sigma delta (∑ - Δ) A/D converter has a fast conversion rate and can update the analog input reading once every 25 ms; Support software configuration integration cycle, filter out process noise and electromagnetic noise, and improve data stability

Measurement accuracy ± 0.03% range (including linear error), temperature coefficient ± 50 ppm/℃. High precision conversion ensures the reliability of collected data. A low temperature coefficient means that accuracy degradation is small when the ambient temperature changes (such as -20-70 ℃ in industrial sites)

Input impedance - FBM201 (current input): 61.5 Ω (nominal)

-FBM201b/c/d (voltage/millivolt input): 10 M Ω current input impedance low, matching 4-20 mA transmitter load requirements; High voltage input impedance to avoid attenuation of sensor output signals

(2) Electrical and environmental adaptability

Power requirements:

Input voltage: 24 VDC redundant power supply (+5%/-10% fluctuation tolerance), supporting dual independent power supplies to ensure uninterrupted operation of the module;

Power consumption: 7 W (nominal), heat dissipation 3 W (maximum), low-power design reduces control cabinet heat dissipation pressure.

Environmental specifications:

Working temperature: -20-70 ℃ (-4-158 ° F), storage temperature -30-85 ℃;

Humidity: 5% -95% (without condensation);

Vibration and impact: 0.75 g (5-500 Hz), in compliance with industrial grade anti vibration standards;

Environmental level: Meets the requirements of ISA S71.04 Class G3 (Harsh, harsh environment), and can withstand complex industrial site conditions such as dust, humidity fluctuations, and sudden temperature changes.

Anti interference capability:

Common mode rejection ratio (CMRR):>100 dB (50/60 Hz);

Differential Mode Rejection Ratio (NMRR):>95 dB (50/60 Hz);

Compliant with EN 61326-1:2013 Class A electromagnetic compatibility (EMC) standard, with strong resistance to electromagnetic radiation and conducted interference.

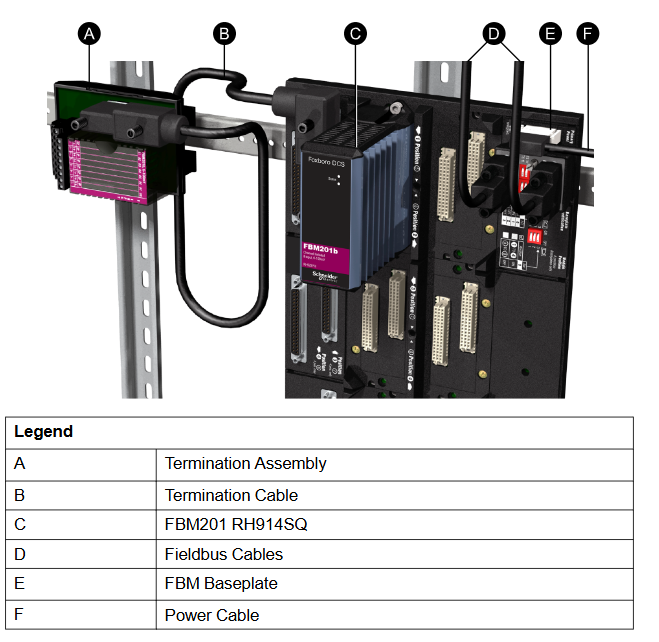

Hardware design and installation configuration

(1) Hardware structure characteristics

Physical protection: Adopting extruded aluminum alloy shell with high mechanical strength, it can protect internal circuits from physical impact and dust intrusion;

Hot swappable design: supports online removal/replacement (Hot Swap), without disconnecting on-site wiring, power or communication cables, reducing system downtime and improving maintenance convenience;

Status indication: The front of the module is integrated with LED indicator lights, which can intuitively display the power status, communication status, and channel fault status (such as overcurrent and signal abnormality), making it easy to quickly troubleshoot problems;

Redundant communication: Communicate with DCS controller (FCP/FCM) through a 2 Mbps redundant fieldbus, supporting A/B dual path switching. If one path fails, it will automatically switch to the other, ensuring uninterrupted data transmission.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA