Honeywell Enhanced Micro TDC 3000 Control System

Full Analysis of Honeywell Enhanced Micro TDC 3000 8-Node Control System Technology

Introduction

In the history of distributed control systems (DCS), the Honeywell TDC 3000 series is undoubtedly a milestone. The enhanced Micro TDC 3000 8-node system (model MT11-520) released in 1995 is the most compact yet fully functional member of this classic family. It compresses the core capabilities of TDC 3000X, including Universal Station (US), Application Module (AM), Network Interface Module (NIM), History Module (HM), and Advanced Process Manager (APM), into two standard cabinets (towers) and achieves inter node communication through a high-speed twisted pair local control network (TPLCN). This article is based on the official 8-Node Enhanced Micro TDC 3000 User's Manual, which fully restores the technical details of this legendary system from six dimensions: hardware composition, communication protocol, installation and wiring, system implementation, operation and maintenance, and spare parts support.

System Overview and Model Differences

The enhanced Micro TDC 3000 offers two basic models:

MX-DTAB01K2: Includes K2LCN processor, 1 Universal Station (US), 1 Advanced Process Manager (APM), 4 MW Memory Application Module (AM), 875 MB Hard Disk History Module (HM).

MX-DTAC01K2: Except for upgrading AM memory to 8 MW, everything else remains the same as before.

In the early days, "version B" was equipped with two US nodes, but after the R500 software version, "version A" became the only basic configuration, and the second US became an optional node. All nodes are equipped with K2LCN processor boards, and the US comes standard with 6 MW of memory and supports "Universal Personality", which can be switched between the operator and engineer interfaces with just one click. The system no longer supports UXS or AXM expansion, but can be connected to standard LCN networks through the LCN upgrade kit.

Hardware architecture: Twin tower four node and Multinode module

The electronic core of the entire system is installed in two cabinets (towers) with similar appearances. Tower 1 (right side) accommodates nodes 1-4, including US, AM, NIM, and optional third/fourth US; Tower 2 (left side) accommodates nodes 5-8, including HM, second US, redundant NIM, and optional computer gateway (CG) or enhanced PLC gateway (EPLCG). Each tower is equipped with a Multinode module, which adopts a 3/3/2/2 backplane layout and can accommodate up to 4 nodes. Each node consists of two circuit boards: K2LCN processor board and corresponding peripheral/personality board.

In terms of peripheral devices:

Display: Available in 20 inch or 21 inch color CRT, supports IDEK MF-5221 (analog knob), IDEK MF-8221 (digital buttons), and HITACHI HM-4821-D (CE certified) models.

Keyboard: Flat membrane operator keyboard with built-in three tone speakers and 16 user programmable keys on the left side; The engineer keyboard adopts a PC-AT layout and supports hot plugging during system operation.

Pointing device: Infrared touch screen or trackball (optional), sharing the J1 interface on the EPDGP I/O card.

Storage: US standard dual 150 MB Bernoulli cartridge drives (compatible with 35 MB media); HM has a built-in 875MB 5.25-inch SCSI hard drive (WREN III or subsequent 512 MB models).

Printer: ASPI-41 dot matrix printer, connected to US via Centronics interface.

Communication Network: TPLCN and LCN Upgrade

The nodes inside and between towers are interconnected through TPLCN (twisted pair local control network). This network is based on the RS-485 electrical standard, with a transmission rate of 5 Mbps. It uses the same token passing protocol as the standard LCN, but eliminates coaxial cables and transceivers to accommodate short distance cabinet layouts. The TPLCN cable uses Honeywell's specialized shielded twisted pair cable (part number 51304505-100, standard 1.5 meters; optional 10 meters), connected through the tower's TP485 card (slots 1 and 9).

When integrating Micro TDC 3000 into larger standard LCN systems, the LCN upgrade kit can be used. The kit includes LCN cabinets, 5/7 slot empty chassis, fans/power supplies, coaxial cables, and WDA modules. At this point, except for the US node, all other nodes need to be migrated to independent modules in the LCN cabinet. The HM hard drive is moved into the WDA, and the TPLCN is replaced by a coaxial LCN. After the upgrade, the system can seamlessly collaborate with other LCN devices such as computing modules, historical modules, etc.

Installation and Wiring: From Site Preparation to EMC Compliance

Environmental requirements: The system is designed for Class C (office) environments, with an operating temperature of 0-45 ° C, a storage temperature of -10-70 ° C, a relative humidity of 10-80%, no condensation, vibration tolerance of 5-22Hz 0.254mm displacement, and 22-500Hz 0.25g. Tower dimensions: height 72cm, width 32cm, depth 58cm, with a single tower weight of approximately 45kg; APM cabinet (double-sided channel) height 210cm, width 80cm, depth 80cm, weight 200kg.

Power supply: Supports 120/240 Vac (+10%/-15%), frequency 47-63 Hz. Tower 1 is fully loaded (1 US+AM+NM+driver) with a typical current of 1.65A and power consumption of about 102W; Tower 2 (HM only) has a typical current of 1.15A and power consumption of about 56W. Each tower requires an independent NEMA 5-15R socket, and international models are equipped with CEE-7 plugs. Surge current limit is 15A@120V .

Wiring points:

All signal cables (video, keyboard, printer, TPLCN, UCN) are connected from the transition panel at the back of the tower, using dedicated cable clamps and shielded crimping.

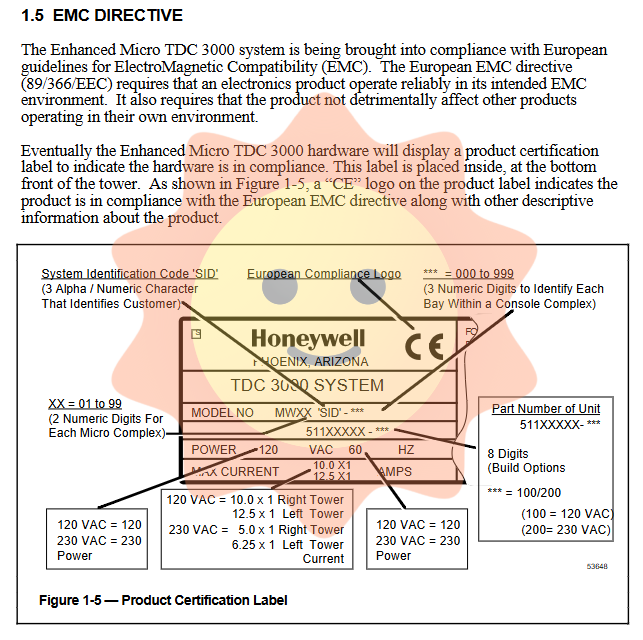

EMC Directive Version: EMC compliant hardware is mandatory for equipment exported to the European Union after 1996. The main differences include: the installation of conductive panels (such as EPDGC, CLIA, TP-485-3) on the I/O board, the use of braided/aluminum foil double shielding for cables, 360 ° conductive wrapping for connector housings, and grounding at both ends of all shielding layers.

UCN process wiring: APM is connected to NIM through UCN (Universal Control Network). The UCN trunk line uses RG-6 coaxial cable, and the branch cable (up to 5 meters long) is introduced into the NIM modulation and demodulation card through the F-type joint on the tower bottom transition panel. The fixed address of the primary NIM is 1, the redundant NIM address is 2, and the address of the PMM module in APM is set to 3 (or 4 when redundant).

System Implementation: Network Configuration, Module Loading, and Data Point Construction

The implementation process of the enhanced Micro TDC 3000 is highly centralized, with most of the preset files already stored in HM volumes.

Network Configuration File (NCF): When the system leaves the factory, NCF.CF is pre-set in the&ASY volume, defining 10 units, area AREA01, node numbers (US: 1,2,8; NIM: 3,4-4; AM: 5; HM: 6; CG: 7), and system parameters (clock source, alarm strategy, volume space, etc.). Users can add CG or EPLCG nodes through online reconfiguration.

Module loading:

US guidance: If HM has automatically guided and>appears on the screen after tower 1 is powered on, press LOAD N and enter UNP to load the universal personality; If HM is not ready, it is necessary to manually load operator personality and NCF/area/button files using&C2 and&C8 cartridge disks.

AM: Select AM node 05 through the system status screen, perform manual loading, select DEFAULT (NET) for both program and data sources, and the status will change to OK after loading.

NIM: Using the same method, select node 03 and automatically restore the preset NIM parameters (network number $NM01N01 $, node allocation THISNIM, loading range NIMandPM) from HM after loading.

APM: Select node 03 on the UCN status screen, execute GRAM LOAD and STORE DATA, and load box point data and I/O configuration from the default source. The I/O card slots 1-4 of the standard double-sided non redundant cabinet are fixed as HLAI, AO, DI, DO, while slots 5-40 are empty.

Optional gateway: CG or EPLCG needs to be loaded from&C8 using empty checkpoints and manually configured with protocol parameters.

Data points: The system has pre-set 1 AM PID point (AM-REG) and 15 APM points (including analog input/output, digital composite, logic, timer, numerical, etc.). The complete parameters are shown in Appendix A. If the cabinet I/O type or slot does not match the preset, the data entity generator (DEB) can be used to modify or create new points.

Custom Features:

Screen editing: The PICS volume already includes sample screens such as KEYLOCK. Users can use Picture Editor to create process flow diagrams, compile them, and store them in the&D01 area.

Free Format Reports: Define the format for printing reports using the Free Format Logs tool.

Button configuration: The blank keys on the left side of the operator keyboard and the PF keys on the engineer keyboard can both be redefined through the BUTTON01 file. The preset file already includes commonly used calls (group display, details, trends, alarm summary, etc.), see Appendix B for details.

CL program: Both the application module and APM support Honeywell Control Language (CL). CL/AM programs need to be loaded into AM through compilers and linkers; CL/APM programs are loaded directly into APM as sequence points.

Regional database: Region AREA01 has been configured with parameters such as 8-point group display, unit trend, system status correlation screen, alarm logs, journals, etc. To install the regional library, you need to specify the path NET>&D01>AREA01 in BUILDER COMMANDS and execute INSTALL ARE.

Operation Guide: Personalized Switching, Keyboard Access, and Monitor Calibration

Personalized loading: Universal personalization allows for the simultaneous use of operational and engineering functions. You can switch between two types of interfaces by pressing CTRL/HELP on the engineer keyboard. If only operational functions are required, the operator's personality can be loaded.

Access level: Due to the lack of a physical key switch in the Micro TDC 3000, the system uses password protected display (SCHEM KEYLOCK) to simulate level three permissions. The default factory password is TDC3000 SUPV (supervisory level) and TDC3000 ENGR (engineer level). Press HELP on the system status screen to bring up the KEYLOCK screen, and enter the password to increase permissions. The password can be modified through the screen editor.

Display adjustment:

IDEK MF-5221 (old model): The analog knob is located below the screen and can adjust brightness, contrast, raster rotation, pillow distortion, vertical/horizontal dimensions, and center.

IDEK MF-8221 (New): The digital buttons are hidden in the sliding drawer, providing energy-saving functions such as automatic size positioning, automatic contrast sensing, and automatic shutdown sensing. It supports color temperature selection (WB1 9300K, WB2 6500K) and user color tone storage.

HITACHI HM-4821-D (CE certified): adopts menu style digital adjustment, supports three adjustable levels of moir é suppression and color temperature, RGB independent gain adjustment, and has complete power management indicators.

The touch screen components can be interchanged between different displays by simply replacing the corresponding borders and fixing buttons.

Maintenance and troubleshooting

Anti static measures: All circuit boards must be plugged and unplugged after power failure, and the operator must wear a grounding wristband. The board can only be held at the edges and must be stored in a conductive bag.

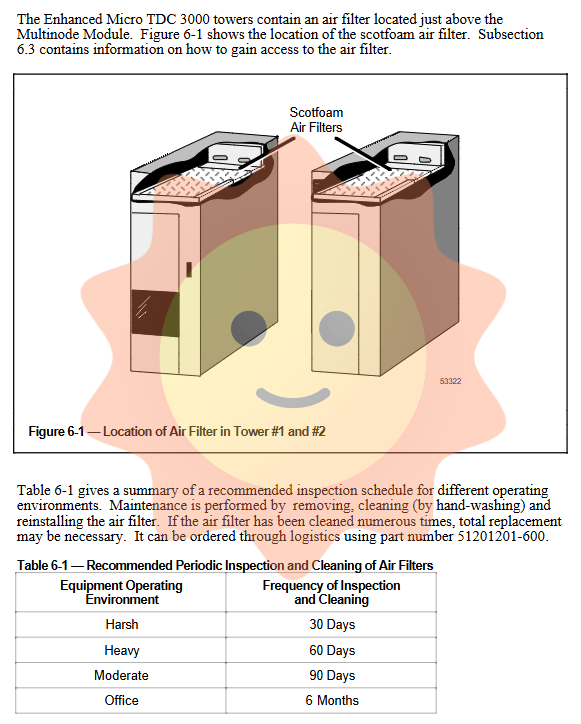

Air filter screen: a washable foam filter screen (part number 51201201 ‑ 600) is set above the multi node module of each tower. It is recommended to clean the harsh environment once a month and the office environment every six months. When cleaning, it is necessary to cut off the main power supply of the tower (unplug the power cord), remove the drive bracket, take out the filter screen, wash it by hand with neutral detergent, air dry it, and reset it.

Fault diagnosis:

Front panel LED: Each node processor board is equipped with a red/green LED and two digital tubes. During power on self-test, the red LED briefly lights up, and after success, the green LED stays on, and the digital display shows the address of this node (1-8). If the red light stays on, record the fault code.

Power/Fan Indication: The power module inside the tower has POWER OK (green), ERROR (red), and FAN ALARM (red) indicator lights. Under normal conditions, only POWER OK lights up.

Hard drive failure: The bottom hard drive power supply of Tower 2 comes with a circuit breaker. If HM does not work, check if the switch trips.

Hardware Verification Testing System (HVTS): HVTS is a set of diagnostic firmware that can be loaded from a cartridge disk and is used to verify subsystems such as LCN, keyboard, video, hard drive, memory, CLI, and system clock. Execute the CON command to output a node configuration list, and execute the REV command to view hardware/firmware versions.

ORU: Section 6.5 of the manual lists nearly 70 types of spare parts, including:

Display and touch screen (51196075-100, etc.)

Keyboard (51401577-100 operator, 51400975-100 engineer)

Hard drive (51196680-100 512 MB)

Circuit board (K2LCN 51401551-XXX, TP485 51304776-100/-200/-300/-400)

CLI interface board (80360206-00151196701-100)

Power supply, fan components, cable components, etc.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands