Foxboro Evo ™ FBM218 module

Foxboro Evo ™ FBM218 module

Core functions and features

(1) Output channel and signal support

Channel configuration: It has 8 isolated output channels, and each channel can flexibly choose two output modes: one is a standard 4-20mA analog output signal, and the other is to superimpose a digital HART frequency shift keying (FSK) signal on the 4-20mA analog output signal, which can be compatible with both standard 4-20mA devices and HART devices.

Communication capability: Each output channel is equipped with a dedicated FSK modem, which can achieve bidirectional digital communication with HART field devices, support HART universal commands, and ensure the connection between field devices and Foxboro Evo ™ Stable integration of the system; The system can receive 2 digital messages per second from each field device, and also supports HART universal, regular operation, and device specific instructions (excluding burst communication mode), which need to be implemented through an intelligent field device configurator (IFDC).

(2) Redundancy Design and Reliability

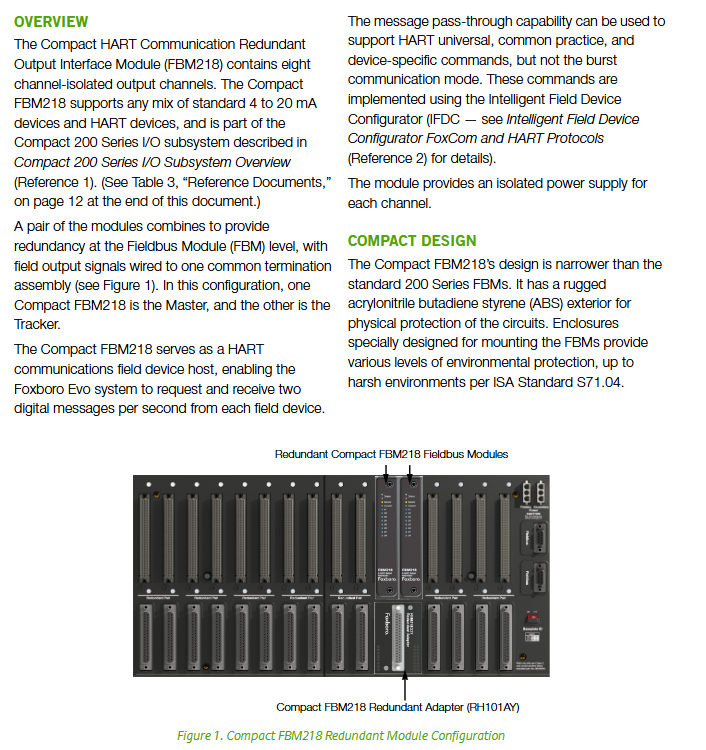

Module redundancy: Adopting module to module redundancy design, redundancy is achieved at the fieldbus module (FBM) level, requiring the use of redundant adapters (RH101AY). In the redundant configuration, one module serves as the "Master" and the other as the "Tracker", sharing a common terminal component (TA), greatly improving subsystem availability.

Fault response: if a module fault is detected, the output of the fault module will immediately drop to 0mA, and the corresponding channel of the normal module will be automatically connected to provide the correct current for the output current circuit to avoid on-site signal interruption; Supports multiple output safety configurable options, including fail safe actions (hold/fallback), analog output fail safe fallback data (set by channel, requiring 0mA output), fieldbus fail safe enable and delay time, and 0mA output setting can also reduce the risk of "high fault current".

Maintenance convenience: when replacing any module, it is not necessary to disconnect the field equipment terminal wiring, power supply or communication cable, nor will it affect the field signal of another module; The module is installed on the Compact 200 series substrate and only requires two screws for fixation, making disassembly and replacement operations easy.

(3) Electrical protection and isolation

Isolation performance: Galvanic isolation (including photoelectric isolation and transformer isolation) is achieved between all output channels, channels and ground, and channels and module logic, and can withstand 600V AC voltage (1 minute) without damage (note: not designed for long-term connection to this voltage level).

Power and load protection: Each channel is equipped with an independent isolated power supply, with an output current design limit of about 25mA. Even if the output field-effect transistor is short circuited, the maximum current is only 100mA. During normal operation, the module outputs a constant current to a load of 0-750 Ω to ensure equipment safety.

Design and Installation

(1) Compact and durable design

Appearance and Material: The module width is narrower than the standard 200 series FBM, and it adopts a sturdy acrylonitrile butadiene styrene (ABS) material shell to effectively protect the internal circuit; Compatible with a dedicated casing that can meet the G3 level (harsh) environmental protection requirements defined in ISA standard S71.04.

Size and Weight: The module has a height of 130mm (5.12 inches), a width of 25mm (0.98 inches), a depth of 150mm (including substrate connectors, 5.9 inches), and a weight of approximately 185g (6.5 ounces). Its compact size makes it easy to install in limited space scenarios.

(2) Installation configuration

Module installation: It needs to be installed on a Compact 200 series 16 slot horizontal substrate, which can be installed on a horizontal DIN rail or a 19 inch rack through an installation kit; Redundant modules need to be installed adjacent to the substrate, and the first module should be located in an odd numbered slot (such as slot 3 and 4), connected to the same terminal component through a redundant adapter.

Terminal Assembly (TA): TA is installed on DIN rails and compatible with various DIN rail specifications such as 32mm (1.26 inches) and 35mm (1.38 inches); We offer two types of wiring: compression type and ring type. Compression type supports solid/multi strand wires of 0.2-4mm ² (24-12 AWG), while ring type supports connectors of # 6 specification (0.5-4mm ²/22-12 AWG); TA material is polyamide (PA), with weights of approximately 181g (compression type) and 249g (ring wiring type), respectively.

Cable requirements: Terminal cables support polyurethane or low smoke halogen-free (LSZH) materials, with a maximum length of 30m (98 feet); The module end is a 37 pin D-type miniature connector, and the TA end is a 25 pin D-type miniature connector. The specific model needs to refer to Table 2 (such as the 0.5m polyurethane cable model RH100BY).

Technical specifications

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA