DeltaV ™ Flex Connect Solutions for Foxboro ™ I/A Series 100 I/O

DeltaV ™ Flex Connect Solutions for Foxboro ™ I/A Series 100 I/O

Core positioning and value

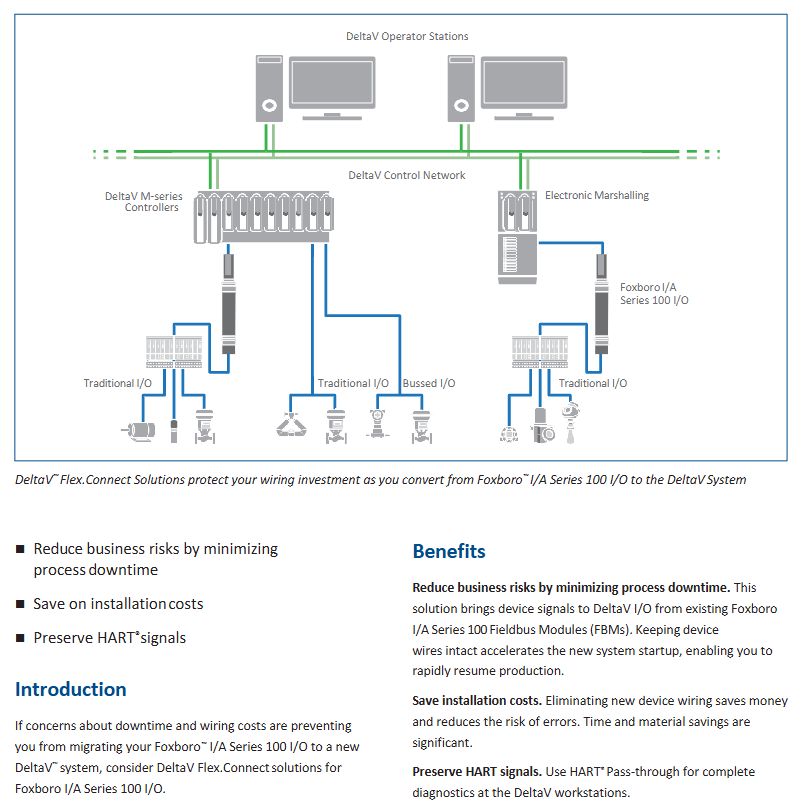

The FlexConnect solution is a modular and scalable connection solution for Foxboro I/A Series 100 I/O systems. Its core value lies in breaking the limitations of traditional I/O systems' fixed cabinet installation. Through remote/distributed connection capabilities, flexible topology configuration, and high reliability design, it adapts to the complex installation environment and diverse equipment access requirements of industrial sites (such as chemical, petroleum, power, etc.), simplifies wiring, reduces installation costs, and improves the overall maintainability and fault resistance of the system.

System architecture and core components

The FlexConnect solution adopts a layered architecture of "main controller remote I/O unit field device", with core components including remote I/O modules, communication links, terminal components, and supporting accessories. The functions and collaborative relationships of each part are as follows:

(1) Core components and functions

Component type, key model/specification, core function

The remote I/O module supports Foxboro I/A Series 100 I/O signal types (such as analog input/output, digital input/output, HART communication, etc.) 1. Local acquisition/output of field device signals (such as 4-20mA, discrete signals);

2. Implement signal isolation and anti-interference processing;

3. Bidirectional transmission of data with the main controller through a communication link.

The communication link supports redundant/non redundant Ethernet and dedicated industrial bus to ensure high-speed and stable data transmission between the main controller and remote I/O modules;

2. Redundant link design avoids communication interruptions caused by single point failures.

Terminal Assembly (TA) is a specialized terminal module that adapts to different signal types. 1. It provides physical wiring interfaces between field devices and remote I/O modules;

2. Support cable fixation and anti loosening design, suitable for different wire diameters (such as 0.2-4mm ² wires).

Power module 24V DC redundant power supply 1. Provides stable power supply for remote I/O modules and terminal components;

2. Redundant design ensures seamless switching in case of power interruption, ensuring the continuous operation of the module.

The protective casing meets the IP rating (such as IP65/IP67). 1. It protects remote I/O modules and terminal components from on-site dust, water vapor, and corrosive gases;

2. Suitable for installation in outdoor or harsh industrial environments.

(2) Topology configuration flexibility

Distributed deployment: Remote I/O units can be installed near field devices (such as equipment side or field cabinets), significantly reducing the length of cables from field devices to I/O modules (traditional solutions require cables to be pulled to the central cabinet, while FlexConnect can reduce wiring by more than 50%).

Multiple topology support: Supports various communication topologies such as star, bus, and ring, and can be flexibly selected according to the distribution density and distance of on-site devices (such as ring topology is suitable for long-distance and multi node scenarios, improving communication redundancy).

Mixed signal access: A single remote I/O unit can simultaneously access multiple types of signals such as analog, digital, and HART, without the need for separate cabinets for different signals, simplifying the system architecture.

Core functions and technical features

(1) High reliability and fault redundancy

Communication redundancy: Supports dual Ethernet links or redundant industrial buses. In the event of a main link failure, the backup link can automatically switch within milliseconds (<100ms) without data loss, ensuring process control continuity.

Power redundancy: The remote I/O unit adopts dual 24V DC power input. When a single power supply fails, the other power supply seamlessly takes over to avoid signal interruption caused by module power failure.

Module level isolation:

Galvanic isolation is implemented between each I/O channel and between channels and module logic circuits (with an isolation voltage of up to 600V AC/1 minute) to prevent module damage caused by on-site signal interference or grounding loops.

The analog channel supports independent current limitation (such as a maximum of 25mA) to avoid the impact of load short circuits on the module.

Fault diagnosis and alarm:

The module has built-in real-time diagnostic function, which can monitor channel faults, communication abnormalities, power supply voltage fluctuations and other issues, and upload alarm information to the main controller through the communication link.

Support local LED indicator light alarms (such as normal power supply, communication status, channel failure), making it easy for on-site maintenance personnel to quickly locate problems.

(2) HART communication compatibility and support for smart devices

HART protocol integration: All analog I/O modules support the HART protocol (compatible with HART 5/6/7 versions) and can overlay digital communication on 4-20mA analog signals to achieve:

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA