Endress+Hauser Prosonic T FMU30 Ultrasonic Liquid Level Measuring Instrument

Endress+Hauser Prosonic T FMU30 Ultrasonic Liquid Level Measuring Instrument

Product core positioning and application scenarios

1. Product positioning

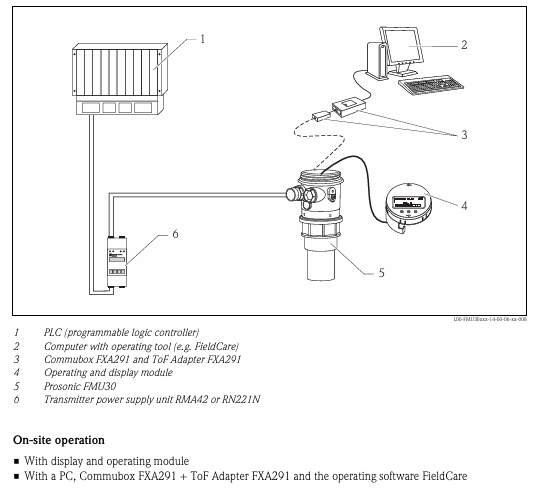

Prosonic T FMU30 is a compact ultrasonic level measurement transmitter that uses non-contact measurement method and is suitable for continuous level monitoring of liquids, paste materials, and coarse granular materials. It supports 4-20mA signal output for system integration.

2. Scope of application

Measurement objects: liquids (such as clean water, sewage, and oil), paste like materials (such as mud and paint), and coarse granular materials (such as gravel and coal).

Measurement range (varies depending on sensor size):

1.5-inch sensor: maximum 5m (16ft) in liquid, maximum 2m (6.6ft) in bulk material, blind spot 0.25m (0.8ft).

2-inch sensor: maximum 8m (26ft) in liquid, maximum 3.5m (11ft) in bulk material, blind spot 0.35m (1.1ft).

Measurement Principles and Core Technologies

1. Measurement principle (time-of-flight method)

The sensor emits ultrasonic pulses onto the surface of the material, which are reflected and received by the sensor.

The device measures the time difference t between pulse emission and reception, combined with the sound velocity c, and calculates the distance D from the sensor diaphragm to the material surface using the formula D=c ⋅ t/2.

Based on the user's preset empty tank distance E, calculate the actual liquid level L using the formula L=E-D.

Built in NTC temperature sensor can automatically compensate for the impact of temperature changes on sound velocity, ensuring measurement accuracy.

2. Key functions

Interference echo suppression: Filter the interference echoes generated by container edges, welds, internal equipment, etc., to avoid misjudging the liquid level.

Linearization function: Supports up to 32 linearization points, can convert measurement values into length, volume, or flow units (applicable for open channel/weir flow calculation), and pre stores a linearization table for horizontal cylindrical tank volume calculation.

Signal output: 4-20mA analog signal, customizable output during alarm (compliant with NAMUR NE43 standard), output damping can be freely set within 0-255s.

Technical parameters and performance indicators

1. Basic electrical parameters

Parameter specifications

Supply voltage 14-35V DC

Power consumption 51mW-800mW

Current consumption 3.6-22mA

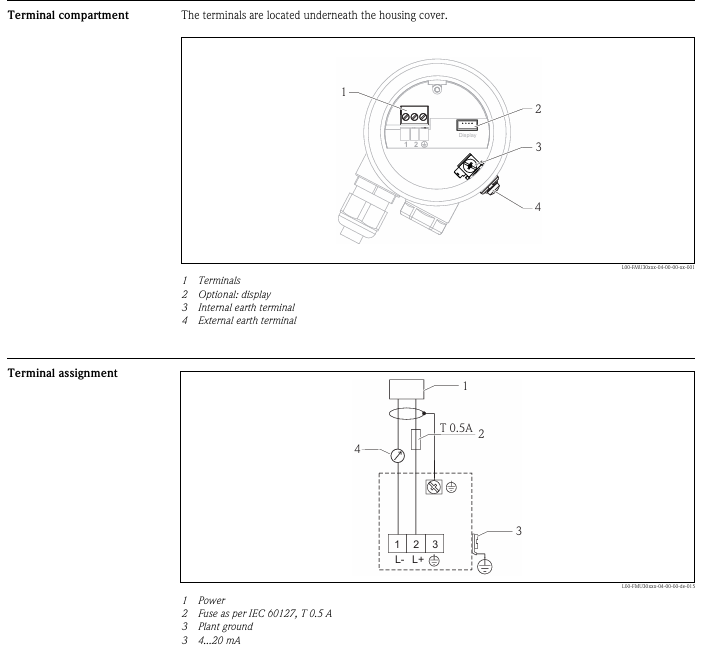

The cable interface has a cross-sectional area of 0.25-2.5mm ² (24-14 AWG), and the cable entry is G/2 "or 1/2" NPT. The recommended cable diameter is 6-10mm

The protective circuit is equipped with reverse polarity protection, radio frequency interference (RFI) protection, and overvoltage spike protection

2. Measurement performance

Resolution: 1mm (0.04in).

Maximum measurement error: ± 0.2% of the sensor's maximum range (in accordance with EN 61298-2 standard, under reference operating conditions).

Typical measurement error: better than ± 3mm (± 0.12in) or 0.2% of the measured distance (whichever is greater).

Response time: Minimum of 2 seconds (depending on parameter settings).

Pulse frequency: Maximum 0.5Hz (varies depending on device type and parameters).

3. Environmental and process adaptability

Category specifications

Operating temperature range: -20 ° C to+60 ° C (-4 ° F to+140 ° F, it is recommended to install a rain cover when using outdoors); Storage: -40 ° C to+80 ° C (-40 ° F to+176 ° F)

Protection level: IP66/IP68 when the shell is closed (24 hours at 1.83m underwater); IP20 when the shell is opened

Vibration resistance meets DIN EN 60068-2-64 standard, 20-2000Hz, 1 (m/s ²)/Hz, 3 × 100min

Electromagnetic compatibility (EMC) complies with EN 61326 standard, industrial environment anti-interference level, EMC impact<1% of full scale

Process temperature -20 ° C to+60 ° C (-4 ° F to+140 ° F)

Process pressure 0.7-3bar abs. (10.15-43.5psi abs.)

Mechanical structure and installation requirements

1. Mechanical specifications

Size and weight:

1.5-inch sensor: weighs approximately 0.75kg (1.65lbs), with process connections of G 1.5 "or NPT 1.5".

2-inch sensor: weighs approximately 0.8kg (1.76lbs), with process connections of G 2 "or NPT 2".

Material: The outer shell is PBT-FR (flame retardant polybutylene terephthalate), the sensor material contact part is PP (polypropylene), and the seal is EPDM (ethylene propylene diene monomer rubber), ensuring chemical compatibility and durability.

Installation specifications

(1) General requirements

Avoid installing in the center of the tank. It is recommended that the distance between the sensor and the tank wall be 1/6 of the tank diameter to prevent reflection interference from the tank wall.

To avoid the measurement path passing through the feeding curtain, the sensor membrane should be perpendicular to the material surface in the application of bulk materials (to avoid the influence of conical accumulation).

Equipment inside the tank (such as limit switches and temperature sensors) should avoid ultrasonic emission angles (11 °), and two ultrasonic measuring devices cannot be installed in the same tank to prevent signal interference.

(2) Special scenario installation

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands