Endress+Hauser Prosonic T FMU30 Ultrasonic Liquid Level Measuring Instrument

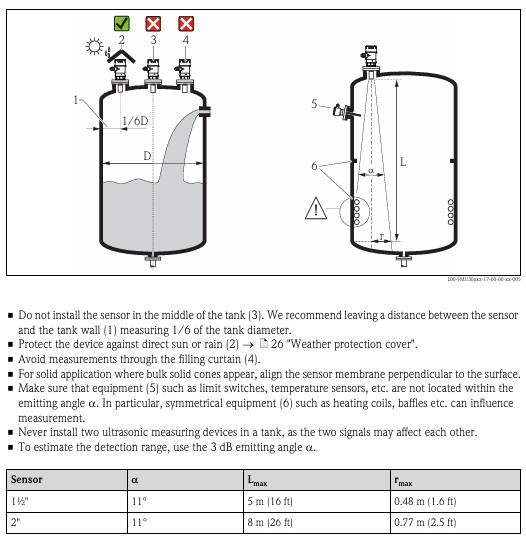

Narrow axis installation: PE or PVC waveguide pipes with a diameter of ≥ 100mm should be used, and regular cleaning should be carried out to avoid contamination affecting the measurement.

Flow measurement (open channel/weir): Installed on the inflow side, near the maximum water level H max (with a blind zone reserved), the sensor diaphragm is parallel to the water surface and centrally installed above the channel/weir.

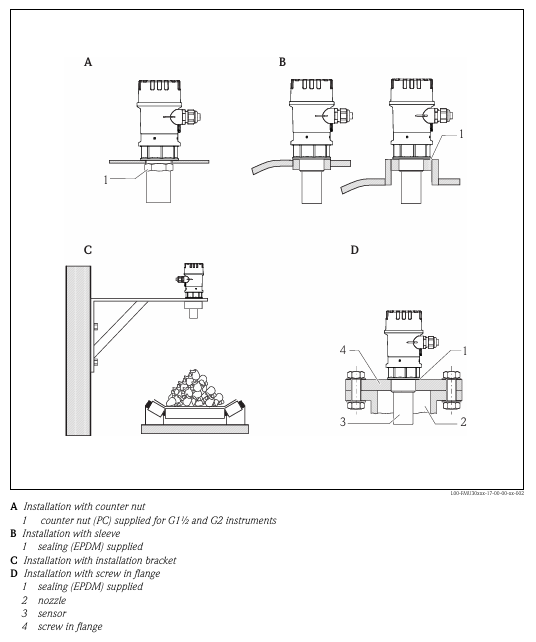

Nozzle installation: If the blind spot requirements cannot be met, a smooth and edgeless nozzle should be used, with a nozzle diameter that matches the maximum length (such as a DN50 nozzle with a maximum length of 80mm and a DN100 nozzle with a maximum length of 300mm).

Operation mode and functional configuration

1. Local operation

Display and buttons: 4-line pure text LCD display screen (supporting 7 languages: German, English, Spanish, French, Italian, Japanese, Dutch), equipped with navigation and confirmation keys, allowing for intuitive viewing of measured values, envelope curves (for fault diagnosis), and alarm information.

Hardware lock: After long pressing the lock button, you need to enter the unlock parameter (100) to operate again to prevent accidental touch.

2. Remote operation

Connect to a PC via Commubox FXA291 (communication box) and ToF Adapter FXA291 (time-of-flight adapter), and use FieldCare software (Endress+Hauser's FDT asset management tool) to achieve remote configuration. The supported functions include envelope curve signal analysis and linearization table editing (import/export).

Equipment data upload/download, measurement point document recording.

Compatible with Ethernet, HART, PROFIBUS PA and other protocols, supporting third-party FDT standard devices.

Certification qualifications and compliance

Certification type specific standards/certification content

CE certification meets the requirements of EU directives, passes relevant tests, and bears the CE mark

Explosion-proof certification ATEX II 1/2G Ex ia IIC T5 Ga/Gb、IECEx Ex ia IIC T5 Ga/Gb、CSA C/US Class I Div.1 Gr.A-D、NEPSI Zone 0/1 Ex ia IIC T5 Ga/Gb

Environmental and safety standards comply with DIN EN 60529 (protection level), EN 61326 (EMC), NAMUR NE43 (alarm signal), EN 61298-2 (measurement accuracy), etc

Ordering Information and Accessories

1. Ordering Code Rules

It is necessary to specify a combination of 7 dimensions of parameters to generate a complete order number, with key parameters including:

010 (certification type): such as AA (non hazardous area), BB (ATEX explosion-proof), IB (CSA explosion-proof).

020 (display and operation): such as G (no local display), H (with envelope curve display+button).

040 (sensor specifications): such as AA (1.5-inch sensor), AB (2-inch sensor).

050 (process connection): such as GGF (G 1.5 "thread, PP material), RHF (NPT 2" thread, PP material).

2. Standard accessories and optional accessories

Standard supply scope: transmitter body, brief instruction manual (KA01054F), CD-ROM document, explosion-proof version including safety instructions, PC material for nuts (GGF/GHF version), EPDM sealing ring.

Optional accessories: Installation bracket (316Ti or galvanized steel material), threaded flange (PP/PVDF/316L material, suitable for different DN specifications), cantilever bracket+installation frame/wall frame, rain cover (PBT material, suitable for -50 ° C to+150 ° C), Commubox FXA291 and ToF Adapter FXA291.

Maintenance and Safety Tips

Daily maintenance: Regularly clean the sensor membrane to avoid contamination affecting ultrasonic transmission; During narrow axis installation, it is necessary to regularly clean the waveguide.

Safety precautions: Explosion proof versions must strictly follow the corresponding safety instructions (such as XA01054F, XA01080F), and installation and maintenance must be carried out by professional personnel; Avoid contact between the sensor and high vapor pressure media (such as ethanol and acetone), and consult the manufacturer for compatibility if necessary.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

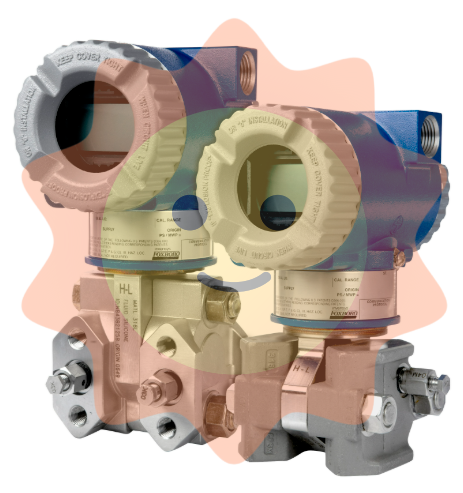

- YOKOGAWA

- TRICONEX

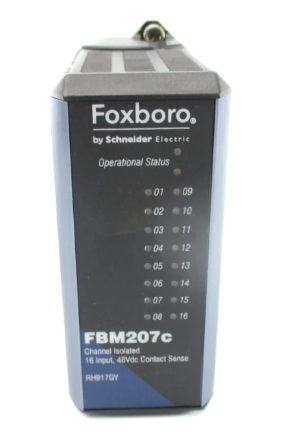

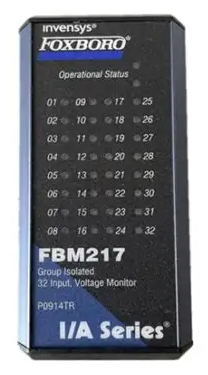

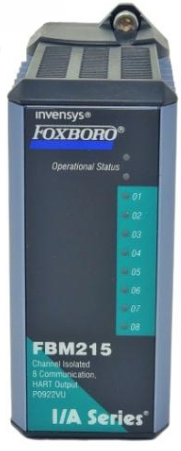

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com