Honeywell Fixed Gas and Flame Detection Product Features

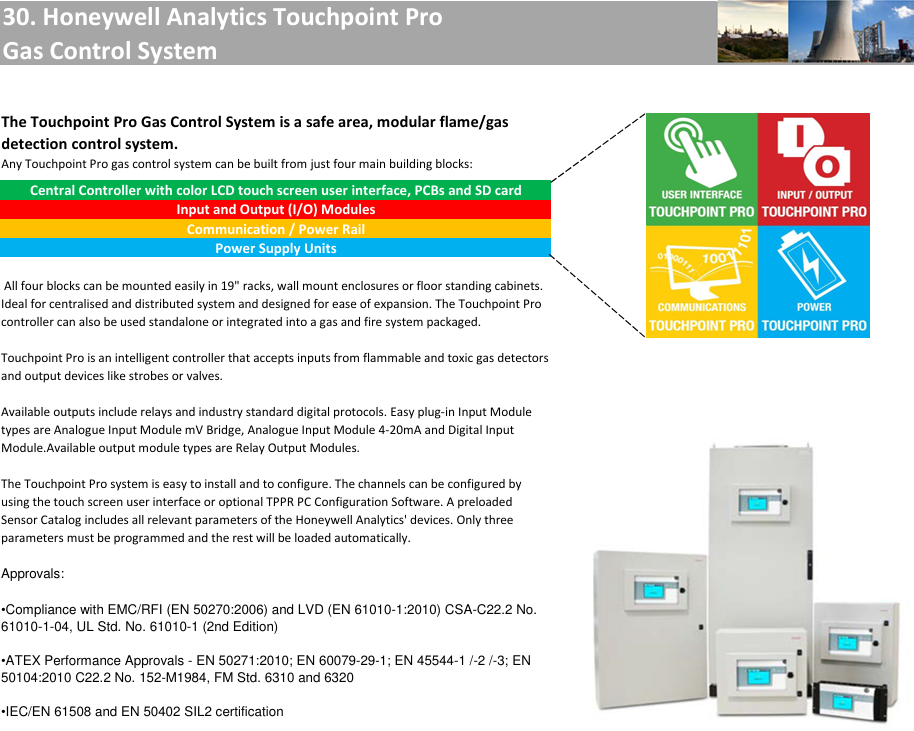

HA series (HA20/40/71/72): HA20/40 supports 2-4 inputs, HA71/72 supports 16-64 inputs, provides relay output and Modbus communication, suitable for small and medium-sized monitoring systems.

Accessories and Calibration Equipment

Calibration kit: specialized calibration tools for different products (such as XNXTOXKit, XCDCOMBKit), including flow meters, tubing, pressure reducing valves, etc., to ensure calibration accuracy.

Installation accessories: pipe supports, sunshades, rain covers, junction boxes, etc., suitable for different installation environments (such as high temperature, humidity, explosion-proof areas).

Alarm device: Sound and light alarm (such as SpectraAlert series), supporting multiple light intensities and sound levels, suitable for sound and light warnings in hazardous areas.

Technical features and advantages

Detection performance: Using various principles such as electrochemistry, catalytic beads, infrared, etc., it covers combustible gases (0-100% LEL), toxic gases (ppm level), oxygen (0-25% Vol) and flames, with fast response time (T90 generally<60 seconds) and high accuracy (± 1.5% LEL or ± 3ppm).

Environmental adaptability: The shell material is mostly 316 stainless steel or epoxy coated aluminum alloy, with IP66/67 protection, a wide working temperature range (-40 ℃ to+150 ℃), vibration resistance, corrosion resistance, and suitable for harsh industrial environments.

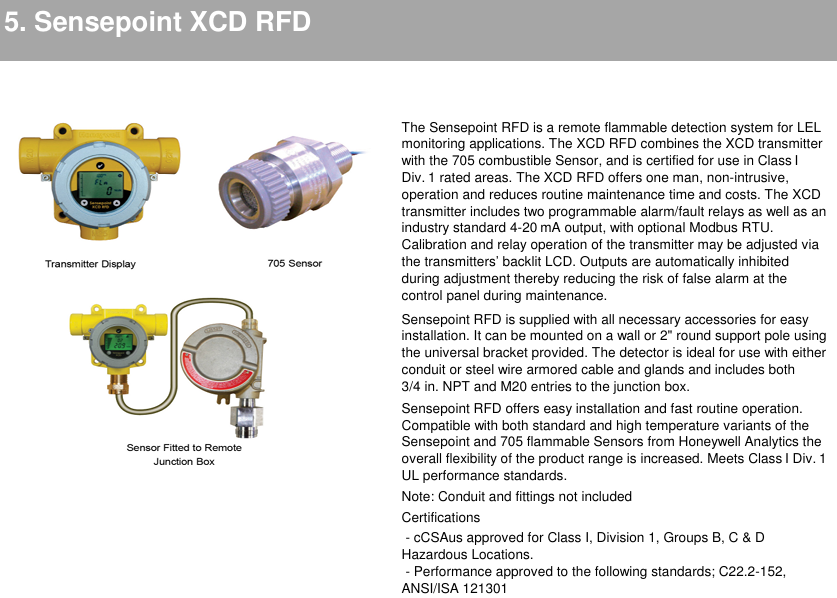

Usability: Non invasive operation (magnetic switch), Bluetooth configuration (some models), plug-in sensor replacement, reducing maintenance costs; Equipped with LCD display and status indicator lights for easy on-site inspection.

Communication and Integration: Supports 4-20mA, Modbus, HART, Foundation Fieldbus, etc., seamlessly integrates with PLC and DCS systems, and enables remote monitoring and data traceability.

Complete certification: Passed major global certifications such as UL, CSA, ATEX, IECEx, CCCF, etc., to meet safety regulations in different regions.

Application scenarios

Petrochemical industry: monitoring of combustible gas (methane, propane) and toxic gas (H ₂ S, Cl ₂) leaks in refineries and chemical plants.

Power industry: SF ₆ and H ₂ testing for gas turbine engine rooms and substations.

Manufacturing industry: VOCs detection in painting workshops and solvent vapor detection in spray painting rooms; Flame monitoring in the welding area of the automobile factory.

Storage and Logistics: Monitoring of toxic gases such as ammonia and chlorine in hazardous goods warehouses.

Semiconductor industry: Special gas (AsH ∝, PH ∝, NF ∝) leak detection.

Precautions

Regulations and standards: The product must comply with local safety regulations (such as NFPA, EN standards), and it is recommended to regularly check the latest regulatory requirements.

Calibration and maintenance: Regularly calibrate according to the manual (usually every 6 months), using certified calibration gases; High pollution environments require increased maintenance frequency.

Installation specifications: Installation in hazardous areas must comply with explosion-proof requirements, and sensor positions should avoid dead corners of airflow, high temperature sources, or vibration sources.

Data update: Product parameters and certifications may be updated. It is recommended to obtain the latest datasheet through the official website. This guide does not constitute a contractual basis.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands