Honeywell Expert LS I/O System

Honeywell Expert LS Series A I/O System: Complete I/O from Rack to Rail

In the field of process control, the reliability, flexibility, and environmental adaptability of I/O systems directly determine the success or failure of automation projects. The Series A I/O system in Honeywell's Expert LS platform is an ideal choice for small and medium-sized process control systems due to its modular architecture, rich signal types, multi network integration capabilities, and rigorous explosion-proof certification. This article is based on the "Expert LS I/O Specifications and Technical Data (EP03-110-400)" technical manual, and provides a systematic technical analysis of the Series A I/O system from five dimensions: system architecture, hardware modules, communication integration, hazardous area applications, and engineering planning.

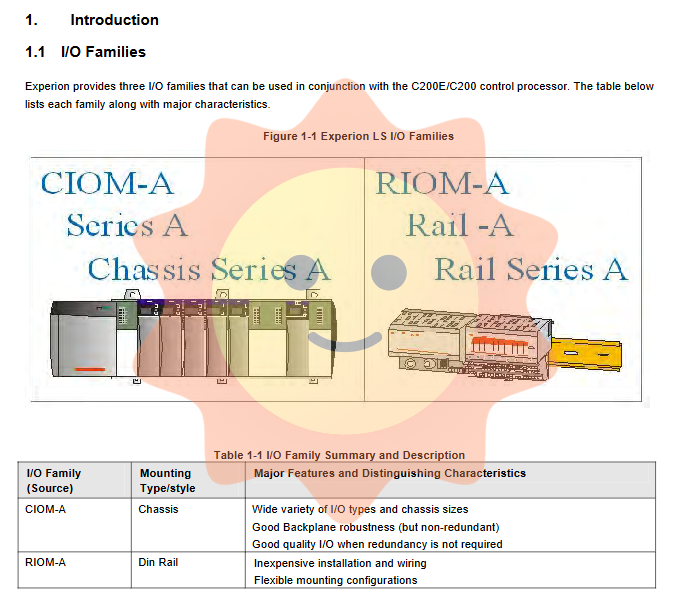

System Overview: CIOM-A and RIOM-A Dual Platform Collaboration

The Expert LS Series A I/O includes two product series, each targeting different physical deployment scenarios:

1. CIOM-A (Rack mounted I/O)

Installation method: Standard rack installation, available in slots 4, 7, 10, 13, and 17.

Core features: High density, high reliability, module adopts single width/double width size, powered and communicated through backplane.

Applicable scenarios: Control rooms or centralized cabinets with high requirements for redundancy and scalability.

Power supply: Dedicated non redundant or redundant power modules (TC-FPCxx2/TC-FPDxx2 and TC-RPCxx1/TC-RPDxx1), mounted on the left side of the rack and not occupying any slots.

Coating options: Model prefix TC (uncoated)/TK (three proof coating), the latter is suitable for corrosive environments of G2/G3 grade.

2. RIOM-A (Rail mounted I/O)

Installation method: DIN rail installation, expanding up to 8 I/O modules through the ControlNet gateway (TC-FCCN01 non redundant/TC-FCCR01 redundant).

Core features: Distributed deployment, simple wiring, flexible installation, support for horizontal/vertical installation and bus extension cables.

Applicable scenarios: on-site distributed I/O, device level control, and renovation projects.

Power supply: External 24VDC power supply (TC-FFPCX1) or power supply through terminal block.

The two platforms can coexist in the same I/O ControlNet network, and achieve seamless integration of centralized and distributed scheduling through C200E/C200 controllers.

CIOM-A Rack mounted I/O: Modular High Density Control Core

1. Rack and power system

Rack model: TC-FXX042/072/102/132/172 (numbers indicate number of slots), corresponding width of 263-738mm, weight of 0.75-2.2kg.

Power specifications:

Non redundant (TC-FPCxx2 AC/TC-FPDxx2 DC): Input 85-132/170-265VAC or 19.2-32VDC, total output power 70W@60 At ℃, the backplane outputs 1.2V/3.3V/5.1V/24V.

Redundancy (TC-RPCxx1/TC-RPDxx1): Dual power supply+rack adapter (TC-RPSCA2), total power 75W@60 ℃, equipped with current sharing, fault alarm, and LED indication.

Power calculation: The power consumption of each module is detailed in Table 7-1 of the manual, and it is necessary to ensure that each voltage bus does not exceed the limit (such as 5V bus limited to 10A).

2. Essentials of Standard I/O Module Specifications

Module model type Channel number Key parameters Terminal type

TC-IAH061 high-level analog input 6 ± 10V/4-20mA, 16 bit, isolated 20 pin TC-TBNH

TC-IXL062 thermocouple input 6 supports B, E, J, K, R, S, T, N, C, D, L, 16 bits, accuracy 0.1% 20 pin TC-TBNH

TC-IXR061 RTD input 6 Pt/Ni/Cu, 16 bits, 0.1% accuracy 20 pin TC-TBNH

TC-ORC081 relay output 8NO+8NC 2A@240VAC , 2A@30VDC , with a lifespan of 300000 cycles and 36 needles TC-TBCH

TC-ODK161 AC output 16 74-265VAC, 2A/point, zero crossing, isolated 36 pin TC-TBCH

TC-ODJ161 DC output 16 24VDC, 2A/point (derating), isolated 36 pin TC-TBCH

TC-HAI081 HART analog input 8 4-20mA/HART, 16 bit, point-to-point 36 pin TC-TBCH

TC-HAO081 HART analog output 8 4-20mA/HART, 15 bits, open circuit detection 20 pin TC-TBNH

3. Special function modules

High speed pulse input (TC-MDP081): 8-channel 0-100kHz counting, 2-channel digital output, 32-bit counter, used for flow and speed measurement.

Serial interface (TC-MUX021): 2-channel RS232/RS422/485, supports Modbus RTU, Allen Bradley DF1, requires FTA (MU-TSIM12/MU-TSIA12) and dedicated cables.

Network module:

ControlNet interface (TC-CCN01/CCR01): single/dual media, 5Mbps, used for C200 and remote I/O communication.

DeviceNet Bridge (1756-DNB): Allen Bradley product, single slot, configured through RSNetWorx.

PROFIBUS DP Master Station (SST-PFBCLX): Made by SST, single width module, supports DP-V1, maximum 496 byte input/492 byte output.

4. Wiring scheme

Option 1: Directly plug and unplug the terminal block (20 pin TC-TBNH/36 pin TC-TBCH) with a wire diameter of 14-22AWG.

Option 2: Remote Terminal Board (RTP), using Allen Bradley 1492 series pre connected cables (1492-HWCAB/HWACAB) to achieve fast connection between IOM and RTP. RTP supports various types such as IFM/RIFM/AIFM/RAIFM/XM, and can support up to 10A relay expansion.

RIOM-A Rail mounted I/O: Pioneer in Distributed Flexible Deployment

1. System composition

ControlNet gateway: TC-FCCN01 (non redundant)/TC-FCCR01 (redundant), occupying 1 node address and driving up to 8 I/O modules.

Terminal block: TC-FTB301 (3-wire)/TC-FTB3T1 (temperature specific), each terminal block corresponds to 1 I/O module, providing on-site wiring terminals and backplane bus expansion.

Bus expansion cable: TC-PKTX30 (30cm)/TC-PKTX90 (90cm), used for separating rail connections.

I/O modules: covering DI/DO/AI/AO/RTD/TC/relays, etc., complementary to CIOM-A functions but with a more compact structure.

2. Key module parameters

Module Model Type Channel Specification Highlights

TC-FIAH81 high-level analog input 8 12 bits, 4-20mA/± 10V, response 4ms

TC-FIA121 high-level analog input 12 16 bits, accuracy 0.1%, isolated

TC-FID161 24VDC digital input 16 leakage type, adjustable filtering, 2.5k Ω impedance

TC-FID321 24VDC digital input 32 leakage type, two sets of 16 channels, 6k Ω

TC-FOD161 24VDC digital output 16 source type, 0.5A/point, short circuit protection

TC-FOD321 24VDC digital output 32 source type, 0.5A/point, two sets

TC-FIR081 RTD input 8-3-wire system, 16 bit, supports Pt/Ni/Cu

TC-FIL081 thermocouple input 8 16 bits, supports B, E, J, K, N, R, S, T

TC-FOR081 relay output 8 2A@240VAC , Form A, Lifespan 100000 times

3. Power supply and power consumption

The gateway is powered by external 24VDC, with a power consumption of 4.6W, and provides 5V/640mA bus current to the I/O module through Flexbus.

The on-site power supply needs to be independently supplied externally, and the module power consumption is detailed in the manual (e.g. TC-FID161 is 6.1W).

4. Integration and Tools

Configure through pre-defined function blocks in Control Builder.

The NTOOLS tool is used for ControlNet network monitoring and gateway firmware upgrades.

The IOTOOL tool supports RIOM-A module calibration.

Network Communication and Control Integration

1. I/O ControlNet architecture

Physical layer: RG-6 coaxial cable (Belden 3092A), 5Mbps, supports repeaters and fiber optic extensions.

Topology limitations:

Each C200 has a maximum of 4 downlink CNIs, and a maximum of 8 uplink CNIs/gateways per downlink CNI.

Each downlink CNI has a maximum of 24 I/O units, and a total of 64 I/O units (including PMIO) per C200.

Redundant configuration: When C200 is redundant, the host rack must not insert I/O modules; CNI supports dual media redundancy.

2. DeviceNet integration

Hardware: Allen Bradley 1756-DNB (firmware v6.2), single slot, supports 125/250/500kbps.

Software: The DNETIF library provides DNET_SM (DNB module), DNETevice (device), and DNET-INCHAN/OUTCHAN (channel) function blocks.

Capacity: Up to 32 DNB modules per C200, up to 64 devices per module, up to 16 input/16 output channels per device, and up to 8 numerical values/32 discrete points per channel.

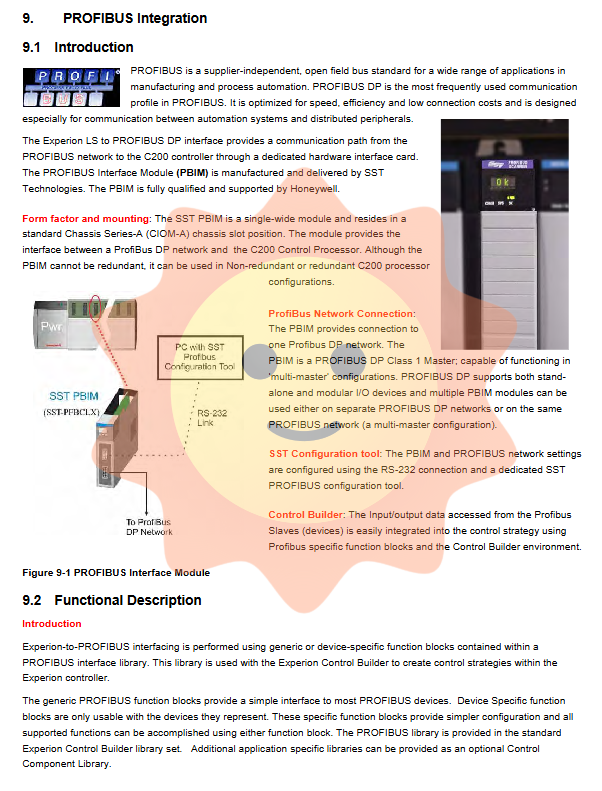

3. PROFIBUS DP integration

Hardware: SST-PFBCLX, single slot, DP-V1 master station, supports 12Mbps.

Configuration: Import GSD files through SST PROFIBUS configuration tool to generate bus parameters.

Capacity: Up to 10 PBIMs per C200, up to 100 slave modules per module, input/output data ≤ 496/492 bytes respectively.

Function blocks: PBI2 Device, PBI2 INCHAN/OUTCHAN Channel, supporting 8/16/32-bit integer and floating-point conversion.

4. Serial communication

TC-MUX021 provides 2 RS232/RS485 channels, supports Modbus RTU and AB DF1, and connects to on-site devices through MU-TSIM12/MU-TSIA12 FTA.

The maximum communication speed is 19.2kbps and supports external cables up to 305 meters in length (MU-KSX series).

Dangerous Area Certification and Entity Concept

1. North American Certification (NEC/CEC)

Grade: Class I, Division 2, Groups A, B, C, D; Class I, Zone 2, Group IIC。

Protection methods: intrinsic safety (IS), non intrinsic safety (NI), explosion-proof (XP), etc.

Temperature group: T4 (135 ℃) or T5 (100 ℃), etc., indicated on the module label.

2. International certification (IEC/CENELEC)

Zone 2 (some modules support Zone 1/Zone 0 via ia).

Standard: EN 50014/50020/50284, ATEX Directive.

Explosion proof mark: such as II (1) 2G EEx ia/ib IIB/IIC T4.

3. Entity parameters and interconnection rules

Intrinsic safety parameters: Ui, Ii, Ci, Li (field equipment).

Related side parameters: Uo, Io, Po, Ca, La (safety barrier/isolation module).

Interconnection criteria: Uo ≤ Ui, Io ≤ Ii, Ca ≥ Ci+Ccable, La ≥ Li+Lcable.

Simple devices: thermocouples RTD、 Passive devices such as dry contacts do not require separate certification.

4. RIOM-A intrinsic safety module

TC-PIA081/082: 8-channel 4-20mA input, supports 2/3 wire transmitters, intrinsic safety parameters Uo=23.7V, Io=92.5mA, suitable for Zone 1.

TC-PIL081: 8-channel TC/RTD input, supports multiple sensors, intrinsic safety parameters Uo=9V, Io=37mA.

TC-PIB161:16 channel NAMUR digital input, intrinsic safety parameters Uo=14.5V, Io=15mA.

TC-POA081: 8-channel 4-20mA output, intrinsic safety parameters Uo=21V, Io=93mA.

TC-POB04:14 channel digital output, load 30-500 Ω, intrinsic safety parameters Uo=27.4V, Io=110mA.

5. Installation requirements

All intrinsic safety modules must be powered through dedicated intrinsic safety terminal blocks (such as TC-PTBC11).

On site wiring must use shielded multi-core cables, with each channel independently shielded.

The cabinet must meet IP54 or above protection and be placed in a non hazardous area or with additional blowing.

Key points of engineering planning and maintenance

1. Coating selection

For G2 (moderate) or G3 (severe) corrosive environments, TK prefix three proof coating modules must be selected, in accordance with ISA-S71.04 standard.

2. Live plug and unplug (RIOP)

Normal area: allowed.

Dangerous Zone (Class I Div 2): Live insertion and removal are prohibited.

3. Fuse

The fuse of CIOM-A power module is internally welded and cannot be replaced.

Some modules of RIOM-A require external insurance (such as TC-FODA81 recommending 1.6A slow break).

4. Environmental specifications

Working temperature: 0~60 ℃ (CIOM-A), 0~55 ℃ (RIOM-A), some intrinsic safety modules -20~70 ℃.

Storage temperature: -40~85 ℃.

Relative humidity: 5-95% non condensing.

Vibration/impact: 5g/30g (CIOM-A), 2g/15g (RIOM-A).

5. Cabinet layout

The vertical spacing between CIOM-A racks is ≥ 203mm, and the horizontal spacing is ≥ 102mm.

The depth of the cabinet is ≥ 203mm.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands