Honeywell Expert PKS Universal Process Cabinet

Honeywell Universal Process Cabinet (UPC): Modular Remote IO for Expert PKS

In the wave of digital transformation in process industries, the deployment of control system I/O is undergoing a fundamental shift from centralized control rooms to distributed on-site installations. As a global leader in process automation, Honeywell's Universal Process Cabinet (UPC) is the core product to address this trend. UPC is not just a simple I/O expansion cabinet, but an integrated platform that extends the entire range of Expert PKS series C-type universal I/O (UIO-2) and low-level analog input (LLAI) modules to hazardous areas, outdoor environments, and remote sites. This article is based on the technical manual "UPC Planning, Installation, and Service Guide (EPDOC-X637-en-B)", and provides a deep technical analysis of the system from six dimensions: system architecture, core components, communication topology, wiring scheme, engineering planning, and maintenance specifications.

UPC system positioning: I/O extension from the central control room to the site

The core design goal of UPC is to free the Series C I/O modules from the central cabinet where the C300 controller is located and deploy them directly in the on-site area near the process unit. This architecture brings revolutionary engineering advantages:

Eliminating wiring cabinets: UPC directly connects to on-site instruments without the need for independent wiring cabinets, reducing signal transmission distance and intermediate terminals;

Control room release: When renovating old factories, there is no need to expand the already saturated control room, and UPC can be directly installed outdoors or in hazardous areas;

Quick deployment: In new projects, UPC is delivered as a pre configured, pre wired, and pre tested full cabinet, requiring only fiber optic connections and power connections on-site;

Extreme environment adaptation: Supports wide temperature operation from -40 ° C to+55 ° C, without the need for external heating or cooling.

The IP66 316L stainless steel chassis (Honeywell part number 50154983-001) is the physical carrier of UPC. This cabinet has the following characteristics:

Material: 316L austenitic stainless steel, suitable for high corrosion environments such as marine and chemical industries;

Protection level: IP66 (dustproof, anti strong water spray), can be directly installed outdoors;

Size: 1300mm high x 800mm wide x 400mm deep;

Weight: Typical configuration is about 136.4kg;

Door lock: 6-point cam lock, requires special tools to open;

Certification: cCSAus, ATEX, IECEx hazardous area certification.

UPC core components: modularity, redundancy, and intelligence

UPC integrates five functional subsystems internally, and all components are delivered through Honeywell pre configured engineering.

1. Power system

Supports three redundant AC/DC power supply solutions, all of which are dual redundant hot swappable configurations:

Power type, part number, output current characteristics

ATDI 600W FC-PUNI2424 25A is efficient and suitable for most scenarios

ATDI power module 51198685-100+51454235-100 power rack 20A modular, with power backplane

Phoenix QUINT 4+50151665-001 (AC/DC)+50165610-001 (DC/DC) 20A wide temperature, high reliability

Redundant logic: Dual power supplies are connected in parallel for current sharing, and in the event of a single fault, the other circuit immediately bears all the load. To ensure redundancy effectiveness, the design load shall not exceed 15.5A of the maximum output of a single power supply.

2. I/O modules: UIO-2 and LLAI

Module IOTA part number, channel number, size redundancy support

UIO-2 CC-TUI041 32 12 inch is (dual module)

UIO-2 CC-TUI031 32 9 inches No (single module)

LLAI CC-TAIL51 16 9 inches No

Maximum capacity:

UIO-2: 96 points (3 redundant IOTA x 32 channels)

LLAI: 128 o'clock (8 IOTA x 16 channels)

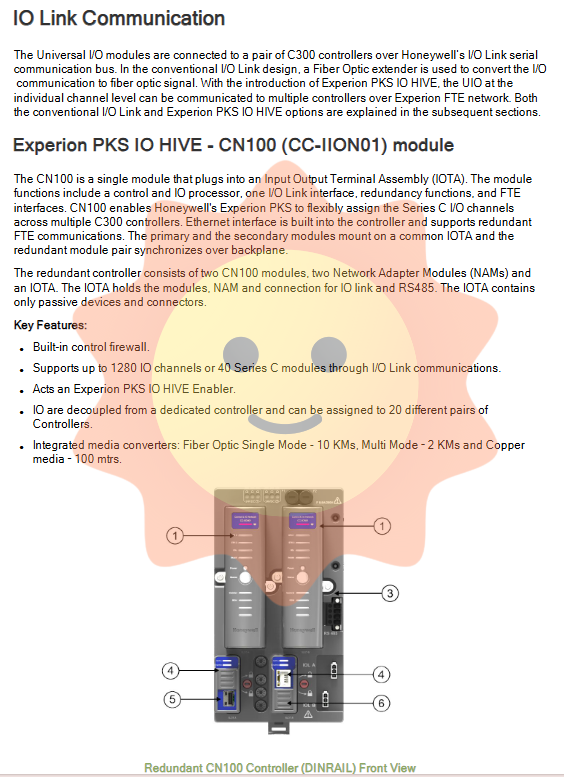

3. Controller and Communication: CN100 IO HIVE

CN100 (CC-IION01) is the intelligent core of UPC, and its functions far exceed traditional remote IO couplers:

IO HIVE architecture: supports dynamic allocation of any I/O channel within UPC to up to 20 pairs of C300 controllers, achieving decoupling of I/O and controllers;

Built in control engine: With the ControlSolver license, CN100 can directly run logic, sequence, and control adjustments, with an execution cycle of 20ms~1s;

Redundant design: dual CN100 modules+dual NAM network adapters+shared IOTA, no single point of failure;

FTE network: Integrated redundant fault-tolerant Ethernet, supporting single-mode fiber (10km) or multi-mode fiber (2km);

Scale: A single CN100 supports up to 1280 I/O channels or 40 Series C modules.

4. Fiber optic I/O link extender (FOE)

For scenarios using traditional I/O Link communication (non CN100), UPC supports MOXA ICF-1150I series FOE modules:

Single mode: ICF-1150I-S-SC-T, SC interface, maximum distance 10km;

Multi mode: ICF-1150I-M-ST-T, ST interface, maximum distance of 2km;

Topology: Supports daisy chain (up to 7 levels) and star chain (up to 16 parallel channels).

5. Attachments and Diagnosis

FC-TALARM01 alarm module: converts 4 normally closed dry contacts into a single analog signal, connects to UIO-2 channel 32, and monitors the power and fan status in real time;

Fan component (51454248-100): used for air circulation inside the cabinet to expand high-temperature operation capability;

ESD grounding point: a dedicated grounding pole located in the lower left corner of the cabinet, which releases static electricity during maintenance.

Communication Topology: Flexible Expansion from Point to Network

UPC supports two completely independent I/O communication architectures, which are mutually exclusive:

1. IO HIVE architecture based on CN100

Fiber optic direct connection to the Expert FTE network;

Support remote deployment of 10km (single-mode)/2km (multi-mode);

I/O channels can be dynamically allocated across controllers to achieve virtualized I/O.

2. Traditional I/O Link architecture based on FOE

Extend the I/O Link serial bus to C300 through optical fiber;

Each I/O Link A/B redundant fiber optic cable is independently wired;

Chrysanthemum chain: A single fiber optic cable can connect up to 7 UPCs in series;

Star shaped: Multiple FOEs on the C300 side are connected in parallel to multiple UPCs.

3. Power supply daisy chain

UPC supports cascading power supply of AC main power supply: The second layer terminal of the AC terminal block (TB2) of the first UPC can be connected to the second UPC, and so on, up to 3 UPCs share the same power supply input line. Each UPC must be independently connected to a protective ground wire.

Wiring and Distribution Solutions: From Traditional Terminals to Intelligent Signal Conditioning

UPC offers four wiring architectures, which users can flexibly choose based on project stage, explosion-proof requirements, and channel density.

1. Direct IOTA wiring (without terminal cabinet)

IOTA itself comes with wiring terminals;

Applicable to non explosion proof, low channel count, and cost sensitive projects.

2. Weidmuller on-site terminal assembly

Passive feedthrough wiring;

Each channel has a testing/disconnection function;

Supports 2-wire system, 3/4 wire system requires an additional 24V power supply terminal;

Intrinsic safety (IC) and non intrinsic safety field wiring are not supported.

3. VIPER Terminal Assembly (Phoenix Contact)

VIPER is the most powerful and high-density wiring solution in UPC:

8 channels per module, 6 wiring points per channel (A/B/C/D/SHC/SHF);

Supports 11 types of IOA (I/O attachments), hot swappable, and on-site reconfigurable:

Feedthrough module (IOA FEED-THRU/EX): 1:1 straight through, 1A;

Simulation protection module: 0.5A fuse, fuse indication, disconnect point, test point, supports 2/3/4 wire system;

Digital protection module: 1A insurance, supports 2/3/4 wire system;

HART I-I transparent transmission module (IOA RPSS-I-I/HART/EX): 3-port isolated relay power supply, supports 0 (4) -20mA input/output, HART transparent transmission;

Relay module: 24V/120V/230V DI/DO, NO/NC optional, 3A contacts.

Rules for intrinsically safe and non intrinsic safe wiring:

When using VIPER, if non intrinsic or intrinsic safety (IC) field circuits need to be supported, the 24V power fuse corresponding to the P1 terminal of the VIPER base must be removed;

The only exception is that the I-I-HART module requires power supply from the P2 terminal and is not subject to this limitation.

4. General signal conditioning component (CC-USCA01)

USCA is the core of Honeywell Universal Marshalling Solution:

16 channel integrated backplane, with a single MTC (Mass Termination Cable) connected to IOTA;

3 on-site wiring screw terminals per channel, with built-in fuses and disconnect points;

Supports 9 types of Signal Conditioning Adapter (SCA), single channel pluggable configuration:

CC-UPTA01: Direct, Passive;

CC-UDIR01/UDOR01: DI/DO relay adapter, low voltage;

CC-ULLI01: Low level input, supports TC, mV, RTD, Ω, 4-20mA output, channel isolation;

CC-UAIA01/UAOA01: AI/AO isolator, 4-20mA, HART, 3-port isolation;

CC-UDXA01: DI/DO self identifying isolator, supporting NAMUR;

CC-UGAIO1/UGAO01/UGDA01: AI/AO/DI/DO intrinsic safety isolation barriers.

Anti misplacement design: The USCA base is equipped with a physical encoding key. When the module is first inserted, the male key clicks into the base and the female key remains in the module. Only modules of the same type can be inserted into this slot in the future.

Engineering Planning and Installation: Rigorous Industrial Standards

The deployment of UPC must follow a series of mandatory engineering guidelines to ensure the effectiveness of IP66 protection, EMC compatibility, and hazardous area certification.

1. Transportation and Storage

Transportation method: shock-absorbing air cushion vehicle, horizontally fixed on wooden pallets, stacking prohibited;

Vibration limit: sine 0.5G;

Outdoor storage: Rainproof cover/sunshade must be used.

2. Installation location

Load bearing requirement: The supporting structure has a load capacity of ≥ 1200 pounds (544kg);

Installation bolt: M10 × 1.5mm, strength grade A2-70;

Space requirement: Adequate heat dissipation space should be reserved around the cabinet, and it is forbidden to block the top air outlet.

3. Cable entry

Unique entrance: Removable gland plate at the bottom of the cabinet;

Protection maintenance: All openings must use IP66 grade cable connectors or metal/high-strength plastic sealing components;

Upper limit of openings on the gland plate: M40 × 30, M16 × 161, etc. (see manual table for details);

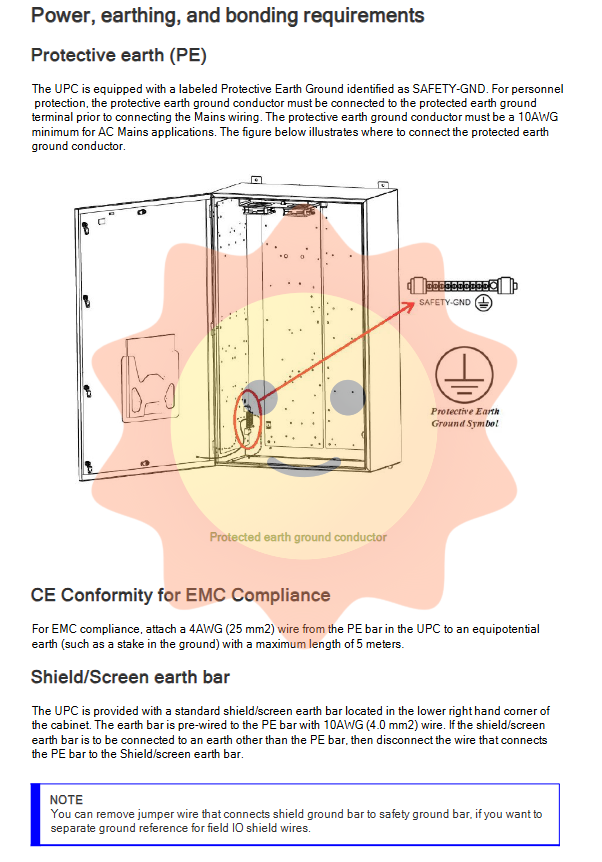

Shielding grounding: A dedicated shielding grounding strip is provided in the lower right corner of the cabinet, which is pre connected to PE at the factory and can be disconnected as needed to achieve single ended grounding.

4. Electrical safety

Protected area (PE): 10AWG (5.3mm ²) minimum wire diameter;

EMC grounding: Connect 4AWG (25mm ²) wires to the equipotential grounding grid, with a length of ≤ 5 meters;

Power supply incoming line protection: The front end must be equipped with a 100% rated continuous load circuit breaker, with a maximum of 30A;

Wiring torque: AC terminal 1.5~2.4 Nm, IOTA terminal 0.5 Nm, VIPER terminal 0.5~0.6 Nm, USCA terminal 0.4 Nm.

5. Environmental restrictions

Working temperature: -40 ° C~+55 ° C (full cabinet certification);

Power output current limit: QUINT 4+is rated to 16A at 55 ° C, while ATDI power rack is only 4A at 55 ° C;

Outdoor use: 316L stainless steel cabinet+sunshade mandatory.

Maintenance and replaceable units

UPC design fully considers on-site maintainability (ORU, Optimal Replaced Units).

1. Module replacement

UIO-2/LLAI module: Power off (IOTA switch OFF), loosen the locking screw (1.3 Nm), and plug and unplug vertically;

CN100 module: Redundant system supports online replacement of backup modules;

VIPER IOA: Press the orange buckle and pull it out vertically without power outage (non hazardous area);

Fuse: Can only be replaced in non hazardous environments and in a power-off state.

2. Fuse data

Position voltage current type

Fiber optic converter 250V 750mA FF

24V DC terminal block 250V 5A T

Fan/ALARM01 250V 3.75A T

AC terminal block 600V 10A FF

DC main power terminal 300V DC 30A-

3. ESD protection

Before maintenance, the ESD grounding point inside the cabinet must be connected;

Pay attention to static electricity accumulation when wiping polymer components inside the cabinet.

Certification and Compliance

UPC has been certified for major industrial and hazardous areas worldwide:

CCSAus: United States and Canada, Class I Division 2 / Zone 2;

ATEX: European Union, II 3 G Ex ic nA IIC T4 Gc;

IECEx: International Electrotechnical Commission Explosion proof Certification;

CE: EMC Directive 2014/30/EU, LVD Low Voltage Directive 2014/35/EU, ATEX Directive 2014/34/EU, RoHS 2011/65/EU.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands