ABB IGCT Technology: A Revolutionary Breakthrough in High Voltage Inverters

To solve this dilemma, ABB Switzerland is exploring a new research and development path aimed at integrating the high-power advantages of IGBT with the core strengths of GTO, ultimately developing GCT (Gate Commutated Thyristor) and further developing it into IGCT, becoming an ideal alternative technology for GTO.

Overall performance with few and no special components, modular mechanical structure, single-chip integration even under high fixed values, high compatibility between power semiconductor control system cooler, stable and easy to center pressure contact technology, easy maintenance, efficiency exceeding 98%, high reliability (MTBF>6 years), small size and light weight, clear interface definition, support for high-power and reliable series operation, and series redundancy design to enhance reliability

(2) Typical application cases

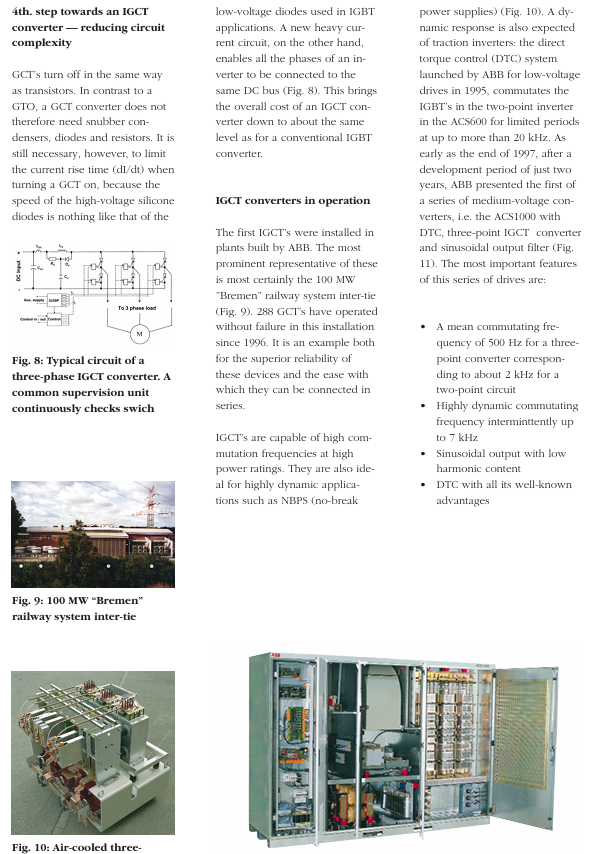

100MW Bremen railway system interconnection device: put into operation in 1996, with 288 IGCTs running without faults, verifying the high reliability and series ease of use of IGCTs.

High dynamic application scenarios: such as uninterruptible power supply (NBPS), traction inverters, etc. Taking the ABB ACS1000 series medium voltage inverter as an example (launched in 1997 with a research and development cycle of only 2 years), it adopts a three-point IGCT inverter and a sine wave output filter, supports direct torque control (DTC), adapts to 2.3kV-4.16kV voltage and 315kW-5MW power range, and can be used for the transformation of existing non speed regulating motors. The debugging difficulty is comparable to that of low-voltage ACS600.

1.5MW air-cooled three-phase phase module: with a commutation frequency of 1050Hz, suitable for high-frequency demand scenarios.

Technological Development History and Future Prospects

(1) Development History (Key Nodes from 1993 to 2003)

1993: Hard drive GTO technology began;

In 1995, 3kA/4.5kV GCT was launched;

In 1997, 6kV/1kA reverse conducting diode (without buffer circuit) and transparent emitter technology were implemented, and the ACS1000 series inverter was launched;

Follow up: Gradually develop 4.5kV/6kA (91mm silicon wafer) GCT and 250A-4kA GCT series, achieve improvements such as integrated coolers and modular driver units, and expand application scenarios.

(2) Future prospects

IGCT technology has firmly established itself in the medium and high voltage field in just a few years, combining the advantages of GTO and IGBT to overcome their shortcomings. With excellent performance, reliability, and cost-effectiveness, IGCT will continue to expand high-power application scenarios and become one of the core technologies of medium and high voltage converters, further promoting the efficient and miniaturized development of the power electronics field.

Possible models that may be used

S-073N 3BHB009884R0021

S-093N 3BHB009885R0021

3ASC25H705/-7

HVC-02B

5SGY35L4510

XTB750B01

751010R0815

SA811F

TP830

CI857K01

PPC902CE101

CI858K01 3BSE018135R1

PM820-1

PM820-2

PM825-1

TC820-1

SD802F

EI802F

AM801F

AM811F

UCD240A101

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com