ABB IGCT Technology: A Revolutionary Breakthrough in High Voltage Inverters

To solve this dilemma, ABB Switzerland is exploring a new research and development path aimed at integrating the high-power advantages of IGBT with the core strengths of GTO, ultimately developing GCT (Gate Commutated Thyristor) and further developing it into IGCT, becoming an ideal alternative technology for GTO.

ABB IGCT Technology: A Revolutionary Breakthrough in High Voltage Inverters

Background and original intention of technology research and development

The development of power semiconductors has always been aimed at pursuing the "ideal switch", which requires the characteristics of low pass state and commutation loss, high commutation frequency, and simple driving circuit. In the low-voltage field, the technological iteration from transistors and Darlington transistors to IGBT (Insulated Gate Bipolar Transistor) has achieved significant results. However, in the medium to high voltage field, the long-term dependence on GTO (Gate Turn Off Thyristor) poses problems such as complex control and limited performance.

To solve this dilemma, ABB Switzerland is exploring a new research and development path aimed at integrating the high-power advantages of IGBT with the core strengths of GTO, ultimately developing GCT (Gate Commutated Thyristor) and further developing it into IGCT, becoming an ideal alternative technology for GTO.

Principles and Breakthroughs of IGCT Core Technology

(1) Core improvement of GCT: solving GTO control problems

GTO has serious control issues and requires an unstable transition zone where both anode voltage and cathode current act simultaneously during shutdown, relying on buffer circuits for support. GCT breaks through this limitation through "hard drive" technology:

The rate of change of gate current reaches µ

(far exceeding GTO's 50 A/µ s), it can switch the current from the cathode to the gate before there is a significant change in the charge distribution between the gate and anode.

Directly switch the device from thyristor mode to transistor mode, with stable and fast turn off process, no need for buffer circuit, and performance close to IGBT.

(2) The Four Key Development Steps of IGCT Converter

Low inductance drive design

To avoid the GCT entering the unstable working zone, the cathode current needs to be turned off within 1 µ s, and the leakage inductance of the gate circuit corresponding to the 3kA GCT should be ≤ 6nH (only 1/50 of the conventional value of GTO).

Low inductance is achieved through a multi-layer connection between the coaxial device connection structure and the driving power output, while using a gate voltage of -20V to balance reliability and cost-effectiveness.

Optimize silicon wafer technology

Hard drive technology allows GCT silicon wafers to be designed thinner without compromising on switch characteristics, combined with plasma engineering technology, significantly reducing losses (compared to GTO of the same specification, the commutation loss is similar but the on state loss is lower).

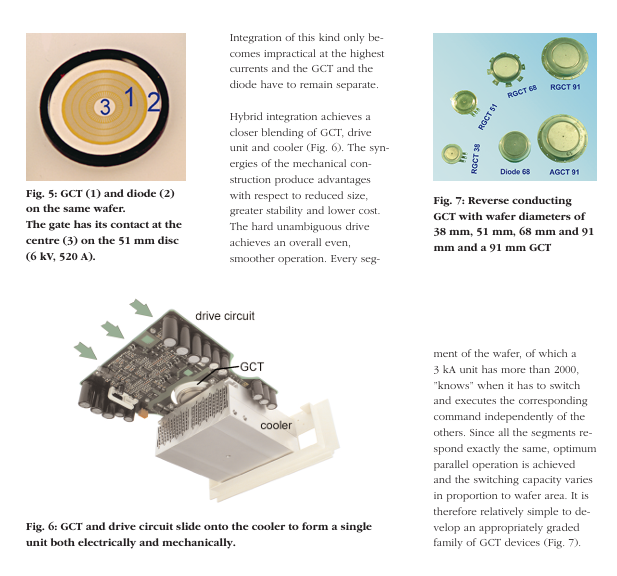

High integration and linear scaling of current

Integration is divided into two levels: one is single-chip integration (integrating anti parallel diodes and GCTs on the same silicon wafer to reduce diode stacking and high current connections); The second is hybrid integration (integrating GCT, driving unit, and cooler to reduce volume, improve stability, and lower costs).

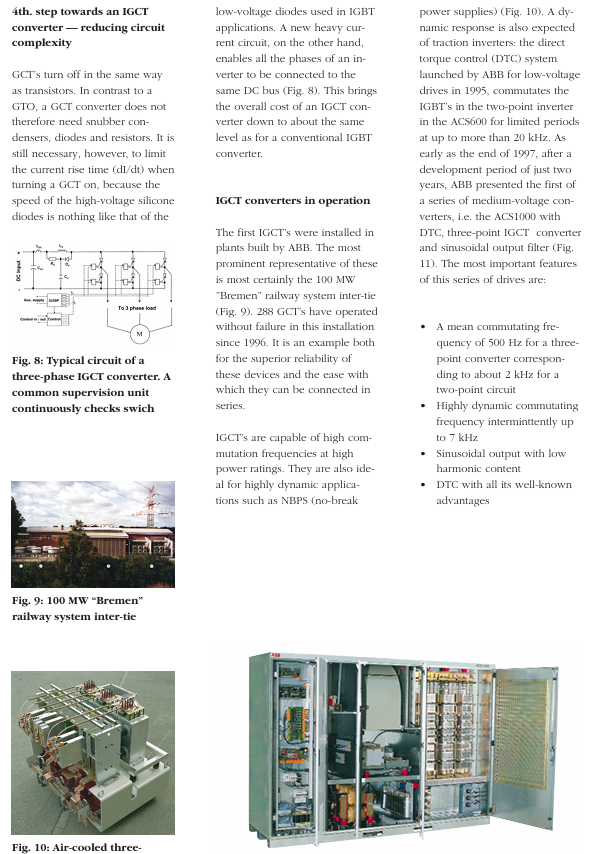

Each unit of the silicon wafer (3kA devices containing over 2000 units) synchronously responds to switch instructions, achieving optimal parallel operation. The current capacity is linearly related to the silicon wafer area, making it easy to develop multi specification GCT series (such as devices with silicon wafer diameters of 38mm, 51mm, 68mm, and 91mm).

Simplify circuit complexity

No buffering capacitors, diodes, and resistors are required for GTO converters, only the current rise rate when GCT is turned on needs to be limited (as high-voltage silicon diodes are slower than low-voltage IGBT diodes).

By adopting a new high current circuit, all phases of the inverter can be connected to the same DC bus, which is comparable in cost to conventional IGBT converters.

(3) Modular design and high-voltage adaptation

Modular component system: In response to the diverse application requirements and small batch size of high-power converters, IGCT adopts modular design, which can cover a power range of 250kW to 100MW through unit series connection and adapt to different scenarios.

Pressure contact technology: Traditional module technology is difficult to handle high voltage and high current. IGCT adopts an improved pressure contact technology, which integrates the driving unit, power semiconductor, and cooler into a single functional unit. It replaces expensive chip parallel arrays with optimized silicon wafers in standard packaging, simplifies manufacturing, reduces costs, and is easy to maintain.

Performance advantages and application cases of IGCT converters

(1) Core performance advantages

Category specific advantages

Component characteristics include high rated voltage, low turn-on and commutation losses, high commutation frequency (intermittent up to 7kHz, average 500Hz for three-point converters, equivalent two-point 2kHz), high silicon wafer utilization, uniform current distribution, linear correlation between current capacity and silicon wafer area, and easy modeling

Circuit design includes a three-phase shared DC bus, a central dI/dt limiter with integrated clamping, simple intermediate circuit connection, safety and reliability under extreme working conditions, and a simple driving circuit (directly coupled with switch signals, no dV/dt or dI/dt regulation circuit required, dual line low-power power supply)

Overall performance with few and no special components, modular mechanical structure, single-chip integration even under high fixed values, high compatibility between power semiconductor control system cooler, stable and easy to center pressure contact technology, easy maintenance, efficiency exceeding 98%, high reliability (MTBF>6 years), small size and light weight, clear interface definition, support for high-power and reliable series operation, and series redundancy design to enhance reliability

(2) Typical application cases

100MW Bremen railway system interconnection device: put into operation in 1996, with 288 IGCTs running without faults, verifying the high reliability and series ease of use of IGCTs.

High dynamic application scenarios: such as uninterruptible power supply (NBPS), traction inverters, etc. Taking the ABB ACS1000 series medium voltage inverter as an example (launched in 1997 with a research and development cycle of only 2 years), it adopts a three-point IGCT inverter and a sine wave output filter, supports direct torque control (DTC), adapts to 2.3kV-4.16kV voltage and 315kW-5MW power range, and can be used for the transformation of existing non speed regulating motors. The debugging difficulty is comparable to that of low-voltage ACS600.

1.5MW air-cooled three-phase phase module: with a commutation frequency of 1050Hz, suitable for high-frequency demand scenarios.

Technological Development History and Future Prospects

(1) Development History (Key Nodes from 1993 to 2003)

1993: Hard drive GTO technology began;

In 1995, 3kA/4.5kV GCT was launched;

In 1997, 6kV/1kA reverse conducting diode (without buffer circuit) and transparent emitter technology were implemented, and the ACS1000 series inverter was launched;

Follow up: Gradually develop 4.5kV/6kA (91mm silicon wafer) GCT and 250A-4kA GCT series, achieve improvements such as integrated coolers and modular driver units, and expand application scenarios.

(2) Future prospects

IGCT technology has firmly established itself in the medium and high voltage field in just a few years, combining the advantages of GTO and IGBT to overcome their shortcomings. With excellent performance, reliability, and cost-effectiveness, IGCT will continue to expand high-power application scenarios and become one of the core technologies of medium and high voltage converters, further promoting the efficient and miniaturized development of the power electronics field.

Possible models that may be used

S-073N 3BHB009884R0021

S-093N 3BHB009885R0021

3ASC25H705/-7

HVC-02B

5SGY35L4510

XTB750B01

751010R0815

SA811F

TP830

CI857K01

PPC902CE101

CI858K01 3BSE018135R1

PM820-1

PM820-2

PM825-1

TC820-1

SD802F

EI802F

AM801F

AM811F

UCD240A101

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com