Woodward 2301A 9907 series electronic load distribution and speed controller

Woodward 2301A 9907 series electronic load distribution and speed controller

Product basic information

1. Core functions and positioning

Core function: Simultaneously achieve two major functions of speed control and load distribution - speed control maintains stable speed of the prime mover (engine/turbine), load distribution ensures proportional load sharing when multiple units are connected in parallel, avoiding single unit overload or uneven load.

Control mode:

Synchronous mode (Isochronous): suitable for single unit operation or multi unit isolated bus parallel connection, maintaining constant speed, requiring automatic power transmission (APTL), import and export control and other load adjustment accessories.

Droop mode: suitable for parallel connection of units to an infinite power grid or with non compatible governor units. The speed decreases with increasing load, and the droop rate can be adjusted through a potentiometer (formula:% droop=(no-load speed - full load speed)/no-load speed x 100).

2. Model and Key Parameters

(1) Model classification (9907 series)

The differences between different models are reflected in the actuator current, action direction, voltage level, and deceleration ramp function. The core parameters are shown in the table below:

Model actuator current action direction voltage level deceleration ramp

9907-020 0-200mA positive high voltage none

9907-021 0-200mA Reverse High Voltage None

9907-238 0-200mA positive low voltage none

9907-239 0-200mA Reverse Low Voltage None

9903-327 0-200mA Reverse Low Voltage None

Forward/Reverse Action: During forward action, the increase in actuator voltage corresponds to an increase in fuel/steam; When reversing the action, the decrease in voltage corresponds to an increase in fuel/steam (default to full fuel when power is off, compatible with mechanical backup governor).

Voltage level: Low voltage type (18-40VDC), high voltage type (90-150VDC or 88-132VAC), to be matched according to the system power supply.

(2) Key technical parameters

Speed range: Select four frequency ranges (500-1500Hz, 1000-3000Hz, 2000-6000Hz, 4000-12000Hz) through switch S1. The factory default is 2000-6000Hz, which needs to be matched based on the rated speed of the prime mover and the number of teeth on the speed measuring gear (formula: sensor frequency=number of teeth on the gear x speed (rpm)/60).

Actuators and sensors: support 0-200mA actuator output; Speed measurement requires the use of a magneto electric sensor (magnetic head), with a minimum signal requirement of 1.0Vrms (starting speed) and a maximum of 25Vrms (rated speed). The gap between the sensor and the gear should be controlled between 0.25-1.0mm.

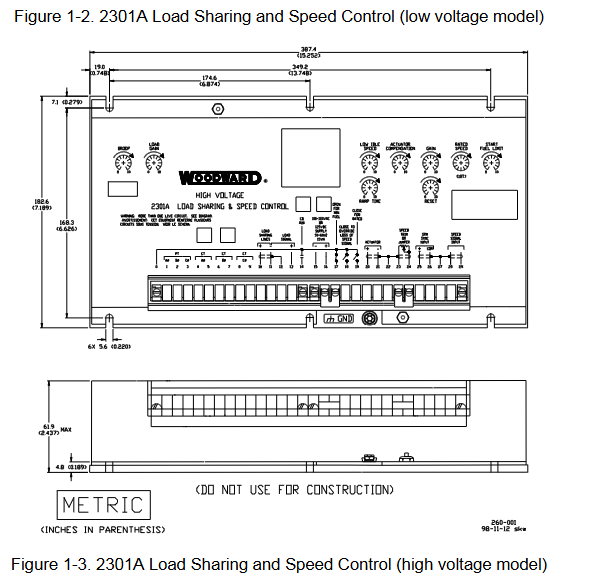

Installation specifications and wiring

1. Installation environment and location requirements

Environmental conditions: working temperature -40-85 ℃ (-40-185 ℉), relative humidity 10% -95% (no condensation); Avoid direct contact with water, vibration sources, and strong electromagnetic interference equipment (such as high-voltage cabinets and high current cables).

Installation restrictions: It is prohibited to install directly on the engine; Reserved heat dissipation space is required (with a ventilation gap of ≥ 3cm and a distance of ≥ 15cm from heating components), and a vertical installation inclination angle of ≤± 45 ° (when there is no forced ventilation).

2. Electrical wiring and shielding requirements

(1) Core interface wiring

The controller terminals are concentrated on the front panel, and the key interfaces and wiring requirements are as follows:

Interface type, terminal number, wiring requirements, precautions

Low voltage power input type (15-, 16+); High voltage type (0, 16) low voltage: 18-40VDC; High voltage: 90-150VDC/88-132VAC requires installation of XT-FIL-1/2 anti-interference filter (mandatory in maritime scenarios); Terminal creepage distance ≥ 6.5mm (compliant with the EU Low Voltage Directive)

Speed sensors 28 (signal+), 29 (signal -), and 27 (shielded) use shielded twisted pair cables. Only one end of the shielding layer is connected to terminal 27, and the other end is suspended with an insulation sensor gap of 0.25-1.0mm. The radial runout of the gear is ≤ 0.5mm

The output of the actuator is 20 (+), 21 (-), and 22 (shielding), and the shielding layer is only connected to terminal 22. It is forbidden to connect the actuator or other grounded actuators. The coil resistance is about 35 Ω, and open/short circuits need to be checked

Load sensor (CT/PT) CT (4-9), PT (1-3) CT secondary output 3-7A (rated 5A), PT secondary 100-120VAC/200-240VAC CT open circuit will generate high voltage, short circuit or power off before wiring

Load distribution lines 10 (+), 11 (-), and 12 (shielded) are shielded twisted pair cables. When multiple units are connected in parallel, the shielding layer is continuously connected without the need for additional relays. The controller is equipped with a built-in load distribution relay

(2) Shielding and anti-interference

All signal cables (speed measurement, actuator, load distribution lines) must use shielded twisted pair cables, with the shielding layer only grounded at the controller end (terminals 22, 27, 12) and the other end suspended to avoid the formation of ground current.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands