KEBA FM 299/A GA1060 fieldbus main module

Option=1: When a module is missing, only a Warning is reported and the CPU continues to run.

This design provides flexibility for degraded operation or temporary debugging with faults.

Electrical connection and wiring specifications: fully shielded, short distance, terminal matching

The GA1060 driver bus is based on the RS-485 differential signal physical layer, with a transmission rate of up to 10 Mbit/s, and imposes strict requirements on signal integrity and anti-interference ability. The FM 299/A engineering manual provides detailed specifications for this.

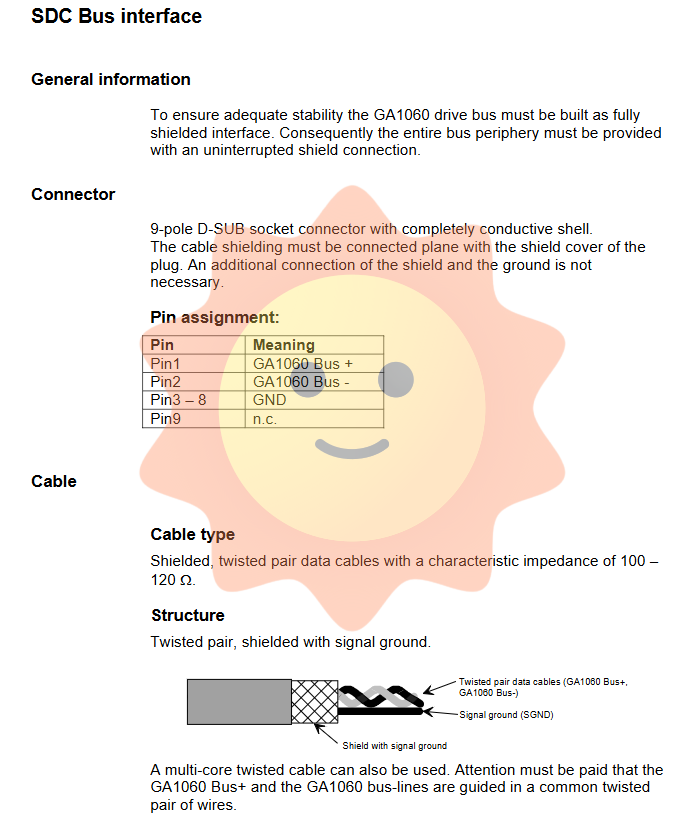

1. Interface and connector

Connector type: 9-pin D-Sub female socket, fully conductive metal shell, ensuring 360 ° shielding continuity;

Pin definition:

Pin1:GA1060 Bus +

Pin2:GA1060 Bus -

Pin3-8: GND (Signal Ground)

Pin9: Vacant

2. Cable selection

Type: Shielded twisted pair, characteristic impedance 100-120 Ω;

Structure: One pair of twisted pair cables carries GA1060 Bus+/-, while the remaining core wires carry GND;

Taboo: It is strictly prohibited to place non system signals (such as PLC digital inputs, third-party device communication lines) and GA1060 bus in the same multi-core cable.

3. Wiring topology

Bus topology: All nodes (FM 299/A master station+QSE driver slave station) are connected to the same bus;

Terminal matching: A 120 Ω terminal resistor must be installed at each end of the bus;

Total length: not exceeding 10 meters, with arbitrary spacing between nodes;

Module position: FM 299/A can be located at any position on the bus (endpoint or middle). If it is located at the endpoint, the other endpoint must be connected to a terminal resistor; If located in the middle, both sides need to be matched with terminals.

4. Shielding grounding

360 ° ring connection: The cable shielding layer must be fully crimped through the metal shell of the connector, and the use of "pigtail" single point grounding is strictly prohibited;

Equipotential: Both ends of the shielding layer need to be grounded, and low impedance equipotential connections should be maintained between the devices inside the control cabinet.

5. Bus terminal board

The manual recommends using a dedicated bus terminal board. If there is no stock available, a 120 Ω resistor can be soldered inside the D-Sub plug and bridged between Pin1 and Pin2.

Diagnosis and Status Indication: Tri color LED and Bus Activity Monitoring

The FM 299/A front panel provides rich visual diagnostic information, divided into two categories:

1. Module status LED

LED color function description

Orange system startup (self-test/initialization)

Green communication is normal with no errors

Red light stays on after power on: module hardware failure;

Lights up after loop operation: communication interruption/bus error

2. GA1060 bus active LED

LED color label function

Yellow TX sends activity, flashing when the main station issues instructions to the driver

Green RX receiving activity, flashing when the main station receives feedback from the driver

Diagnostic logic:

During normal operation, TX/RX should flash according to the control cycle pattern;

If TX is constantly on or off and RX is inactive, it usually indicates a bus physical layer fault (cable breakage, missing terminal resistance, address conflict);

The red status LED combined with TX/RX status can quickly locate the fault area.

Technical specifications: Industrial grade compact design

1. Electrical parameters

Logic power supply: 5V DC, powered through K-Bus backplane;

Maximum power consumption: 1.0W;

Safety level: Level III (EN 61131-2);

Overvoltage category: II.

2. Mechanical dimensions

Front panel width: 22.5 mm;

Module total width (including K-Bus plug): 32.5 mm;

Module height: 120mm;

Installation depth: 100mm;

Weight: 130 grams.

3. Environmental conditions

Meets the requirements of EN 61131-2 for industrial environments;

Working temperature: 0 ° C~+55 ° C (refer to K2-200 system specification);

Storage temperature: -40 ° C~+70 ° C.

4. Certification and Standards

UL 508: Industrial Control Equipment Certification;

UL - listed: fully listed;

IEC 61131-1/-2: Programmable Logic Controller Products and Hardware Standards.

Application scenarios and historical value

The FM 299/A module was born around 2006, during a critical period when servo drive technology was transitioning from pulse direction control to high-speed dedicated buses. Sanyo Denki's GA1060 bus belongs to the manufacturer's proprietary real-time Ethernet/serial bus predecessor, with a 10 Mbit/s rate and deterministic periodic communication capability.

This module has played a central role in the following scenarios:

Fully electric injection molding machine: multi axis servo drive synchronous control (injection, mold opening and closing, ejection, mold adjustment);

Die casting machine picking robot: servo walking axis and joint axis cooperate;

High speed packaging equipment: fly shear, chase shear electronic cam synchronization.

With the comprehensive migration of industrial communication to general open buses such as EtherCAT and PROFINET IRT, the FM 299/A and GA1060 buses have gradually been replaced by KEBA's new generation KeDrive D3 and KeControl C5 with EtherCAT solutions. However, in the market for the renovation and spare parts maintenance of a large number of existing K2-200 old equipment, this module still plays an irreplaceable role.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands