KEBA KeControl C1 CP 03x: Highly Integrated Embedded Industrial Controller

KEBA KeControl C1 CP 03x: an embedded controller designed for high-density I/O and precision processes

In the field of industrial automation, especially in large-scale equipment such as injection molding, die-casting, extrusion, etc., controllers not only require powerful computing cores, but also must directly face hundreds or thousands of sensors and actuators, and complete closed-loop adjustment under strict real-time requirements. The CP 031/Z, CP 033/Y, and CP 033/Z CPU modules in the KEBA KeControl C1 series are tailor-made embedded controllers for such scenarios. They are based on Motorola PowerPC processors, equipped with VxWorks real-time operating system, and integrate massive digital I/O, high-precision analog channels, dedicated temperature measurement interfaces, and multiple industrial bus interfaces on the same hardware platform, achieving a highly integrated control solution of "one machine, one cabinet".

Product positioning: The central brain of K2-200 module system

The CP 03x series module belongs to KEBA's mature K2-200 modular control system. As a central processing unit, it works in conjunction with various I/O expansion modules through a backplane bus, and carries an extremely rich on-board I/O, enabling many small and medium-sized applications to complete all control tasks without any expansion. This design significantly reduces system complexity and control cabinet volume, as well as reducing the risk of contact failures.

This series includes three models:

CP 031/Z: Basic type, balancing I/O quantity and cost;

CP 033/Y: Enhanced I/O configuration;

CP 033/Z: The highest specification, providing the most I/O channels and higher power supply.

The three modules maintain the same processor performance and software compatibility, allowing users to flexibly select based on the number of machine I/O points and achieve precise cost control.

Core hardware architecture: mature, reliable, and high-performance

1. Processor and Memory

The CP 03x series uses Motorola PowerPC 400MHz processors, which reflects KEBA's pursuit of long-term supply stability and industrial grade real-time performance. The PowerPC architecture has excellent interrupt response characteristics and low power performance in the embedded field, coupled with 128 MB SDRAM system memory, capable of handling complex PLC logic, motion control algorithms, and multitasking scheduling. The module is equipped with an additional 512 kB battery buffer SRAM to maintain critical process parameters and counter values during power outages, without the need to reset to zero every time the device is turned on.

2. Real time operating system

Unlike the Linux FlexCore platform commonly used in KEBA high-end controllers, the CP 03x series uses the VxWorks real-time operating system. VxWorks is known for its hard real-time deterministic scheduling and extremely small kernel footprint, and has unique advantages in microsecond level interrupt response, which is very suitable for the demand of microsecond level fast cutting response in the injection molding process of injection molding machines.

3. Program and Data Storage

Firmware, application programs, and recipe data are stored in Compact Flash Type I cards. CF cards have excellent seismic resistance and industrial temperature adaptability, are easy to replace, and support quick on-site maintenance without software. Users can download and debug projects through Ethernet or USB interfaces.

4. Diagnosis and operation interface

The front of the module is equipped with a 7-segment digital diagnostic display screen, status LED indicator lights, and mode selection switch. During the startup process, the 7-segment screen displays self-test codes and error codes; During normal operation, it can be configured to display CPU load, cycle time, or custom status values. This design allows operators to determine the health status of the controller without the need for a computer, greatly improving on-site troubleshooting efficiency.

On board I/O: a versatile interface optimized by the industry

The most prominent feature of the CP 03x series is its industry-specific I/O board, which highly integrates traditional I/O channels that require multiple expansion modules to accommodate, especially optimized for commonly used signal types in plastic machinery and die-casting equipment.

1. Digital Input (DI)

Number of channels: CP 031/Z and CP 033/Y provide 32 channels; CP 033/Z provides 48 routes.

Electrical characteristics: Complies with EN 61131-2 Type 1 standard, input voltage "1" is 15~30V, and "0" is -3~5V.

Special function: The first two inputs (DI/PIO, DI/VII) are designed as speed measurement inputs and can receive frequency signals from 0.5Hz to 100Hz. It has a built-in 16 bit counter and is directly used to monitor the position of hydraulic valve cores, shaft speed, or flow meter pulses.

Update cycle: Minimum 1ms, meeting general switch quantity acquisition requirements.

2. Digital output (DO)

Number of channels: CP 031/Z provides 40 channels; CP 033/Y and CP 033/Z provide 56 channels.

Drive capability: rated voltage 24V DC, single channel rated current 2A, simultaneous rate of 50% per group. This means that in typical applications, medium-sized solenoid valves and contactor coils can be directly driven without the need for additional intermediate relays.

Protection and diagnosis: The output stage has short-circuit continuous protection and short-circuit diagnosis functions. When an output short circuit is detected, the module automatically cuts off the corresponding channel and reports to the upper computer to avoid PCB burning.

Inductive load handling: Up to 24 output channels can withstand 1J @ 0.2Hz of inductive load energy, while the remaining channels can withstand 100mJ @ 0.2Hz. This parameter has been specifically strengthened for frequent opening and closing of hydraulic valves.

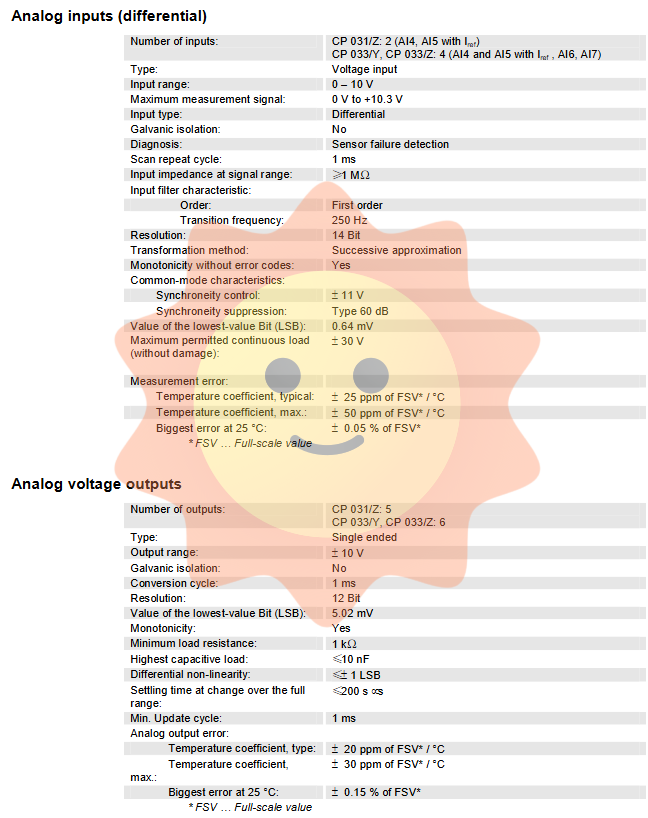

3. Analog Input (AI)

Single ended input: 3 or 4 channels, 0~10V range, 14 bit resolution (1 LSB=0.64mV). Each channel provides an independent 10V reference voltage output (up to 20mA), which can directly supply power to potentiometers or proportional sensors. Built in sensor disconnection detection, once the signal exceeds the normal range, it will be reported.

Differential input: 2 or 4 channels, same 0~10V range, 14 bit resolution, typical common mode rejection ratio of 60dB. Suitable for long-distance transmission or situations with ground potential difference signals.

Accuracy index: Maximum error at 25 ° C ± 0.05% of full scale, typical temperature drift ± 25ppm/° C, belonging to the category of high-precision analog acquisition.

4. Analog Output (AO)

Voltage output: 5 or 6 channels, ± 10V range, 12 bit resolution (1 LSB=5.02mV), minimum load 1k Ω. Used to control proportional valves, frequency converters, servo drive speed commands.

Current output: 3 or 4 channels, using PWM chopping method to simulate current source. Output current 1A ± 5%, PWM switching frequency up to 20kHz, typical 5kHz. The output power is 25W per channel, with a total power of 90W. This design can directly drive proportional electromagnets and hydraulic proportional valve coils without the need for external power amplifiers, which is the core advantage of the CP 03x series in hydraulic applications.

5. Temperature measurement input (TC)

Number of channels: CP 031/Z provides 7 channels; CP 033/Y and CP 033/Z provide 8 channels.

Sensor type: Supports J, K, and L type thermocouples with ranges of -32~+500 ° C, -60~+1200 ° C, and -40~+850 ° C, respectively.

Electrical isolation: Complete isolation between channels and control systems, with a withstand voltage of 707V DC, effectively suppressing ground loop interference and common mode noise.

Accuracy and Resolution: 14 bit resolution, maximum absolute measurement deviation ± 1.5 ° C at 25 ° C, typical value ± 1 ° C. The maximum deviation within the entire operating temperature range (0-55 ° C) is ± 2 ° C.

Cold end compensation: supports internal terminal temperature compensation, and can also achieve high-precision compensation through external dedicated sensors TE 220/A, with errors reduced to ± 0.5 ° C. This feature is crucial for applications that require precise control of mold temperature.

Communication Interface: Diversified Interconnection Capability

The CP 03x series integrates rich communication interfaces within a compact body, allowing it to function as an independent control station and integrate into distributed control systems.

CAN interface

Compliant with CANopen specifications, it can be used to connect K2-200 remote I/O stations, smart sensors, or other CAN devices. The baud rate software can be set and supports multi master communication.

Serial interface

It can be switched to RS-232-C or RS-485-A through software and is suitable for connecting third-party devices such as barcode scanners, frequency converters, and text displays.

Ethernet interface

10/100 Mbit/s adaptive, supports TCP/IP, Modbus TCP, OPC UA and other protocols, making it easy to connect to factory MES systems or for remote maintenance.

USB 2.0 interface

Full speed, high power, can be used for program upload and download, connecting USB flash drive for data recording, or directly connecting mouse and keyboard for local debugging.

LVDS graphic interface

Designed specifically for connecting KEBA Kemro series industrial panels, it supports high-resolution, high refresh rate local human-machine interface display without the need for an additional graphics card.

External temperature sensor interface

Optional TE 220/A sensor for precise measurement of terminal temperature and high-precision cold end compensation of thermocouples.

Mechanical Structure and Power Supply Specifications

The CP 03x module adopts a flat installation method and is horizontally installed on the back wall of the control cabinet through the fixing hole on the back of the shell. The dimensions are 410mm wide, 140mm high, and 50mm deep, occupying minimal space. Weight approximately 1778g, protection level IP20 (to be installed in a closed cabinet).

The power supply adopts 24V DC, which complies with EN 61131-2 standard and allows a fluctuation range of 19.2V~30V. Maximum power consumption: CP 031/Z and CP 033/Y are 125W, and CP 033/Z is 153W. The module is equipped with an external replaceable fan to ensure reliable heat dissipation during long-term continuous operation.

Environmental adaptability and certification

Working temperature:+5 ° C~+55 ° C, meeting the environmental requirements of the vast majority of industrial sites.

Storage temperature: -40 ° C~+70 ° C.

Relative humidity: 10%~95%, no condensation.

Anti vibration/impact: fully compliant with EN 61131-2 standard, suitable for installation next to injection molding machines and die-casting machines with strong mechanical vibration.

Typical application scenarios and process value

The design soul of the CP 03x series lies in reducing system costs and improving process performance. Taking injection molding machines as an example:

48 digital inputs can directly collect the status of doors, top pins, safety doors, and mold sensors;

56 digital outputs directly drive hydraulic valves, water pumps, and heating contactors;

4-channel analog differential input combined with 0-10V reference voltage, accurately reading the position of the electronic ruler;

6-way ± 10V analog output control servo pump or proportional valve;

4-channel 1A current output directly drives proportional pressure valve and proportional flow valve;

8-way isolated thermocouple input for real-time monitoring of barrel, nozzle, and mold temperature.

All I/O is completed within the same controller, with a control cycle as low as 1ms. Combined with KEBA's unique Fast Cut Off algorithm, it can achieve a turning point accuracy of 32 microns at injection speeds of hundreds of millimeters per second, significantly reducing burrs, shortening molding cycles, and reducing scrap rates.

In addition, CP 03x can also be applied to control the clamping force of die-casting machines, synchronize the multi-stage temperature and screw speed of extruders, and achieve dual closed-loop position/pressure in hydraulic presses.

Inheritance and Evolution: The Evergreen Tree of KeControl C1 Family

Although KEBA has launched new generation controllers such as KeControl C5 and KeDrive D3 based on Intel multi-core architecture and Linux FlexCore platform, the CP 03x series still holds an irreplaceable position in specific industries due to its ultimate integration, mature stability, and deep optimization of traditional hydraulic systems. It shares the same engineering design philosophy as the new controller and sets a benchmark in terms of I/O density, anti-interference ability, and direct drive capability.

For OEM manufacturers pursuing low cost, high reliability, and no need for frequent expansion, the KeControl C1 CP 03x series remains a highly competitive choice to this day.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands