ABB M10x Motor Control and Protection Unit (1TNA920500R0002)

Precise protection: covering common motor faults such as overload, grounding faults, and voltage anomalies to avoid equipment damage;

Flexible control: supports multiple drive types such as direct start (DOL), reversible start (REV-DOL), and soft start, adapting to different motor operation requirements;

Intelligent Interconnection: Supports industrial bus protocols such as Modbus RTU and PROFIBUS-DP, and can be connected to distributed control systems (DCS) or PLCs for remote monitoring and parameter configuration;

Scenario adaptation: Suitable for small and medium-sized motors in the industrial field (such as pumps, fans, compressors), especially for scenarios that require high reliability protection and remote control (such as chemical, manufacturing, and power auxiliary systems).

ABB M10x Motor Control and Protection Unit (1TNA920500R0002)

Core positioning and target scenario

M10x is an intelligent motor control and protection device launched by ABB, which provides an integrated solution of "protection+control+monitoring" for motors based on current/voltage measurement and maintenance data monitoring. Its core value lies in:

Precise protection: covering common motor faults such as overload, grounding faults, and voltage anomalies to avoid equipment damage;

Flexible control: supports multiple drive types such as direct start (DOL), reversible start (REV-DOL), and soft start, adapting to different motor operation requirements;

Intelligent Interconnection: Supports industrial bus protocols such as Modbus RTU and PROFIBUS-DP, and can be connected to distributed control systems (DCS) or PLCs for remote monitoring and parameter configuration;

Scenario adaptation: Suitable for small and medium-sized motors in the industrial field (such as pumps, fans, compressors), especially for scenarios that require high reliability protection and remote control (such as chemical, manufacturing, and power auxiliary systems).

Product classification and core differences

The M10x series is divided into two basic types based on functional complexity, and further subdivided by communication protocol and power specifications. The core differences of each category are shown in the following table:

Classification dimensions, specific types, core functional differences, applicable scenarios

Function type M101 (basic type) - protection based solely on current measurement (such as overload, short circuit);

-No voltage related functions;

-Support basic control (such as contactor feeding, direct start) and simple motor control with only current protection (such as small fans)

M102 (Advanced Type) - Based on current and voltage measurement, with added voltage related protection (such as undervoltage and overvoltage);

-Support complex controls such as soft start and reversible start;

-Support parameter monitoring (such as voltage, power) for motors that require multidimensional protection and complex control (such as process pumps)

Communication Protocol - M (Modbus RTU) supports Modbus RTU protocol (RS485 interface), suitable for small and medium-sized networking (up to 32 nodes per bus) and docking with PLC or local control systems

-P (PROFIBUS-DP) supports PROFIBUS-DP V0/V1 protocol, supports cyclic/non cyclic data transmission, multi master station mode, and is suitable for industrial bus networking to access large DCS systems (such as ABB AC800M, Siemens PCS7)

The power specifications of 24VDC/110VAC/240VAC digital input (DI) voltage are consistent with the power specifications, and 24VDC needs to be matched according to the on-site power supply for DC control system, and 110/240VAC is used for AC power supply scenarios

Core hardware components and accessories

The M10x system consists of a main unit, an operation panel, connecting cables, and optional accessories. The functions, models, and parameters of each component are as follows:

(1) Main unit (core control module)

The main unit is the core of M10x, integrating electronic control circuit and built-in current transformer (CT), with key parameters:

Built in CT range: 0.24~63A (when the rated current of the motor exceeds 63A, an external CT is required);

Installation method: The bottom comes with a DIN rail buckle (supporting horizontal installation), and optional screw accessories can be used for vertical installation;

Digital input (DI): 24VDC/110VAC/240VAC (consistent with power specifications), used for local control signal input (such as start stop commands);

Core model example:

Function Type Communication Protocol Power Specification Model (ID Number)

M101 Modbus RTU 24VDC 1TNA920611R0001

M101 PROFIBUS-DP 240VAC 1TNA920733R0001

M102 Modbus RTU 110VAC 1TNA920622R0002

M102 PROFIBUS-DP 24VDC 1TNA920711R0002

(2) Operation panel (local human-machine interface)

All M10x main units must be equipped with an operation panel for local monitoring, control, and parameter configuration, which can be divided into two types:

Panel model, core function, adaptation scenario model (ID number)

MD21- with LCD display screen (displaying parameters and fault codes);

-Equipped with LED indicator lights (power, operation, fault);

-Support control buttons (start stop, reset) and navigation buttons;

-Scenario 1TNA920500R0002 (document core model) with mini USB port (for parameter configuration) requiring visual parameter monitoring

MD31- Only equipped with LED indicator lights (without LCD display screen);

-Support basic control buttons and reset;

-Scenario 1TNA920500R0001 with lower cost, requiring only basic status indication and no parameter viewing

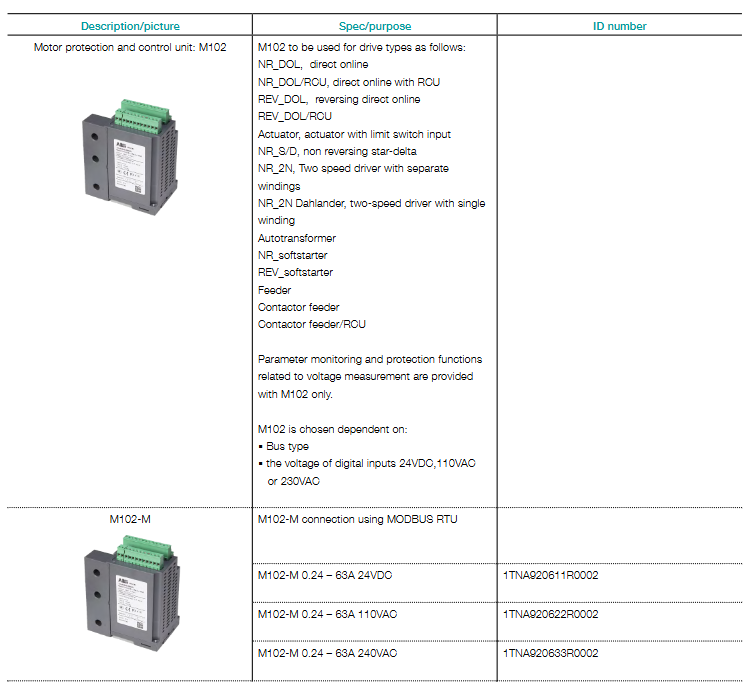

(3) Connecting cables

Used for signal connection between the main unit, operation panel, and expansion module (such as AO11), key models:

Cable model, length, interface type, function, usage, model (ID number)

TA201 1.2m RJ11 main unit at both ends connected to MD21/MD31 panel (standard configuration) 1TNA920005R2101

TA204 0.2m two end RJ11 main unit connected to AO11 analog output module 1TNA920005R2106

TK201 2.5m with one end USB and one end mini USB operation panel (MD21/MD31) connected to computer (parameter configuration) 1TNA920005R2102

(4) Optional accessories

Optional expansion components can be selected according to on-site requirements to enhance system functionality:

Accessory Type Core Function Model (ID Number)

Grounding fault CT (RCT) measures residual current to achieve grounding fault protection, supports 1A/5A two rated currents, window diameter 35/70/105mm, 1TNA911005R1001 (LNG35 1A), 1TNA911005R1004 (LNG70 5A), etc

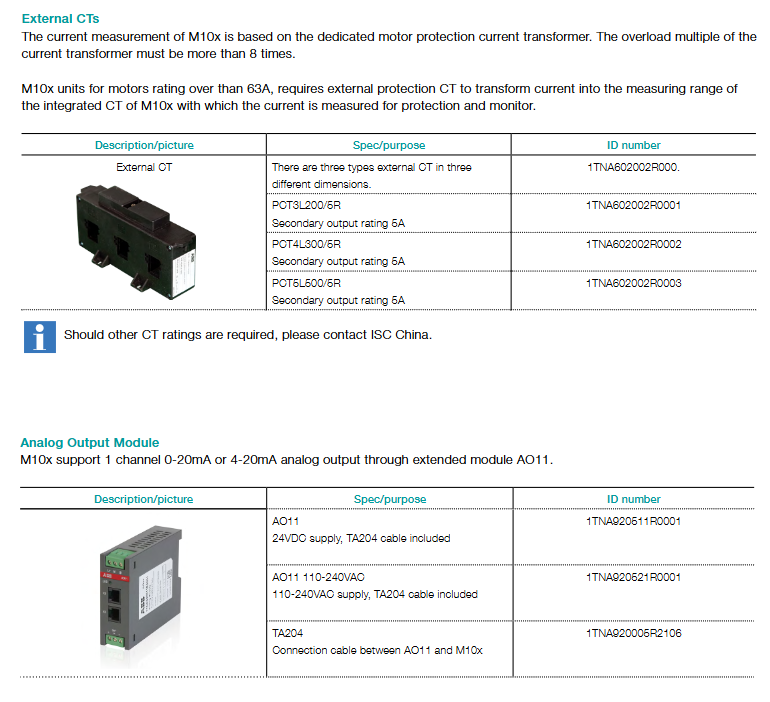

When the external CT motor current is greater than 63A, convert the high current to the built-in CT range (secondary output 5A), support 200/300/500A primary current 1TNA602002R0001(PCT3L200/5R)、1TNA602002R0003(PCT5L500/5R)

The Analog Output Module (AO11) provides 1 channel of 0-20mA/4-20mA analog output (such as motor current, power signal), supporting 24VDC or 110-240VAC power supply 1TNA920511R0001 (24VDC), 1TNA920521R0001 (110-240VAC)

Parameter configuration software (PS201) includes MCUSetup software (parameter download/update), operation manual, GSD file, supports Windows 2000/XP/7/8 1TNA920100R0001

Label paper/USB protective cover MD21/MD31 panel LED label (A4 size, 36 sheets/page), mini USB port protective cover (10 pieces/pack) 1TNA920005R2105 (label paper), 1TNA920005R2107 (USB cover)

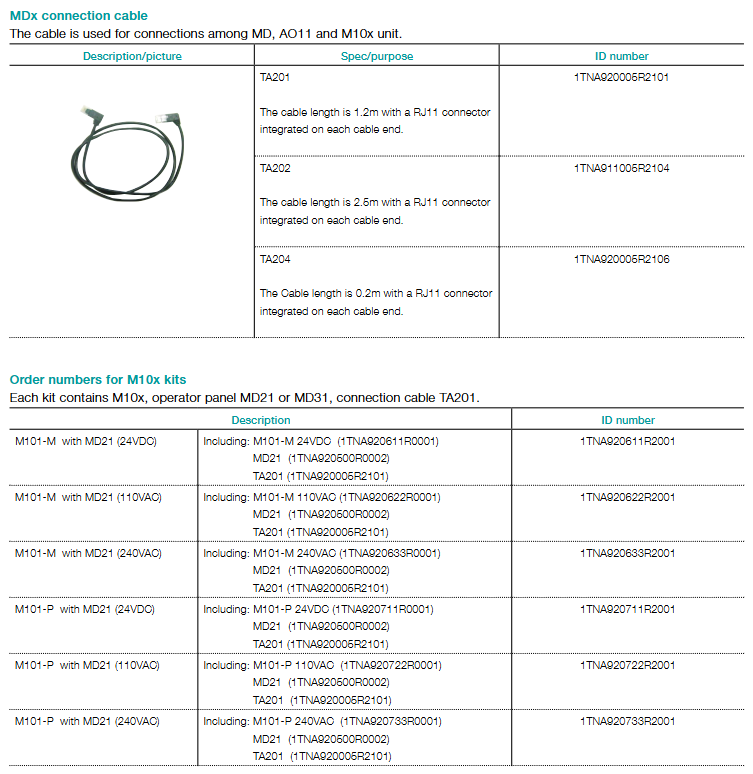

Pre configured kits and ordering information

To simplify the selection process, ABB provides pre configured kits (including main unit, operation panel, and standard cables) without the need to order individual components. Common kit models are shown in the table below (taking MD21 panel as an example, MD31 kit model suffix is "R30XX"):

Kit description includes component kit model (ID number)

M101-M + MD21(24VDC) M101-M 24VDC(1TNA920611R0001)+ MD21(1TNA920500R0002)+ TA201 Cable 1TNA920611R2001

M101-P+MD21 (240VAC) M101-P 240VAC (1TNA920733R0001)+MD21+TA201 cable 1TNA920733R2001

M102-M+MD21 (110VAC) M102-M 110VAC (1TNA920622R002)+MD21+TA201 cable 1TNA920622R002

M102-P+MD21 (24VDC) M102-P 24VDC (1TNA920711R0002)+MD21+TA201 cable 1TNA920711R2002

Ordering precautions

Model matching: It is necessary to clarify the "functional type (M101/M102)+communication protocol (- M/- P)+power specification (24VDC/110VAC/240VAC)+operation panel (MD21/MD31)" to avoid incompatibility caused by model errors;

Firmware version: The latest firmware version is provided by default. If a specific old version is required, it should be specified in the order;

Accessory selection: When the motor current is greater than 63A, an external CT must be used, and the CT specification should be selected according to the rated current of the motor (such as PCT3L200/5R for 200A motors);

Document requirements: Supporting documents can be requested (such as "M10x User Guide" 1TNC911112D0205, "AO Module Guide" 1TNC920201D0201).

Technical specifications and compliance

(1) Key technical parameters

Category parameter details

Current measurement built-in CT: 0.24~63A; External CT: 200/300/500A (secondary 5A); Measurement accuracy: ± 1%

Communication interface RS485 (Modbus RTU/PROFIBUS-DP), baud rate: 9600~115200bps (configurable)

Digital input (DI) 2 channels (24VDC/110VAC/240VAC), used for control commands such as start stop and reset

Working environment temperature: -25~+60 ℃ (operation), -40~+85 ℃ (storage); Humidity: 5%~95% (no condensation)

Protection level: main unit IP20 (to be installed inside the control cabinet); Operation panel IP40 (panel installation)

(2) Compliance certification

Safety certification: UL/CSA certification (compliant with UL 508, CSA C22.2 No.14 standards), IEC/EN 60947-6-2 (specialized standard for motor protection);

Electromagnetic compatibility (EMC): compliant with EN 61000-6-2 (industrial environment immunity) and EN 61000-6-4 (industrial environment emission);

Environmental compliance: Compliant with the EU RoHS Directive (2011/65/EU), restricting the use of hazardous substances.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com