GE Mark VIe Control System

GE Mark VIe Control System

Introduction

The Mark VIe control system is a flexible platform suitable for various application scenarios, with high-speed networked input/output (I/O) functionality, supporting simplex, dual, and triple redundant systems. It adopts industry standard Ethernet communication for connecting I/O, controllers, operators and maintenance stations, as well as third-party systems. The ControlST software suite (including the ToolboxST toolset) is used for programming, configuration, trend analysis, and diagnostics of the system, providing high-quality, time consistent data at the controller and factory levels to assist in effective management of control system equipment. In addition, the Mark VIeS safety control is an independent safety control system suitable for safety critical applications that comply with the IEC 61508 standard. It also uses the ControlST software suite to simplify maintenance, but has unique certified hardware and software modules.

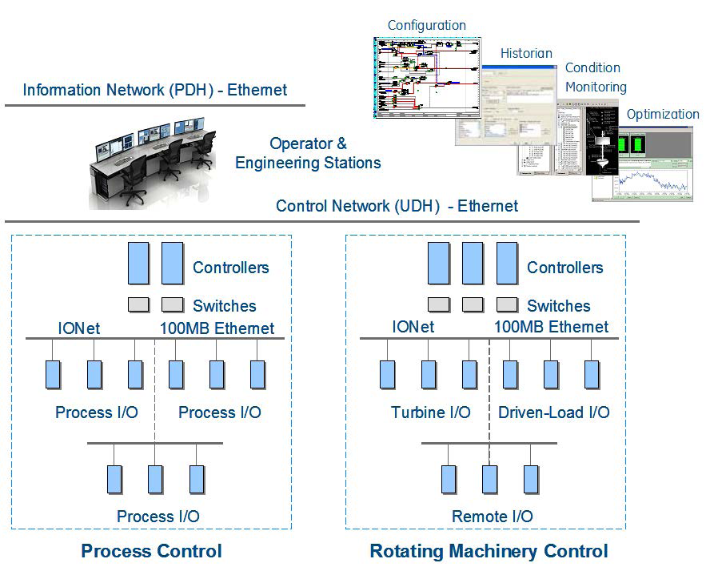

System Overview

Core components: With a single board controller as the core, it includes a main processor, redundant Ethernet drivers for communicating with networked I/O, and additional Ethernet drivers for controlling the network. The main processor and I/O modules adopt a real-time multitasking operating system, and the control software is stored in non-volatile memory in a configurable control block language. It also supports IEEE 854 32-bit floating-point format and Sequential Function Chart (SFC).

I/O Network (IONet): It is a dedicated full duplex point-to-point protocol that provides a deterministic high-speed 100MB communication network, suitable for local or distributed I/O devices, supports single, dual, and triple redundancy configurations, and also supports copper and fiber optic interfaces.

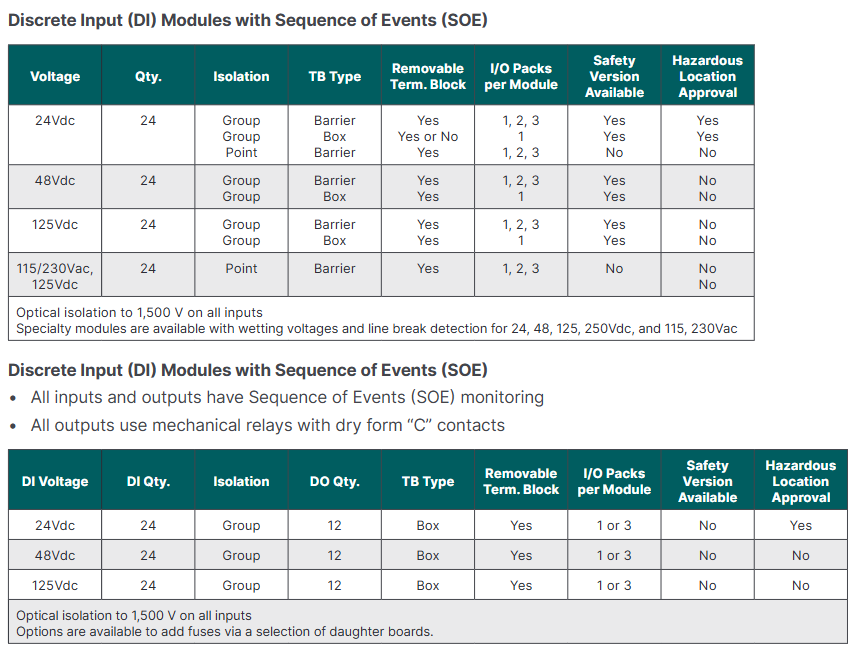

I/O module: It consists of three parts: terminal board, terminal block, and I/O package. There are two types of terminal boards: T-type and S-type. T-type usually assigns inputs to three independent I/O packs, while S-type provides a set of screws for each I/O point. The I/O packet contains two Ethernet ports, a power supply, a local processor, and a data acquisition board, which can be added according to application requirements to expand I/O capabilities. It supports simplex, dual, or triple redundant configurations.

Redundant configuration: Provides multiple redundancy options for processes with different levels of criticality, involving multiple control components such as power supply, power supply, I/O pack, Ethernet port, IONet, and control network. The dual redundant system transmits inputs to dual controllers through dual IONets, while the triple redundant system processes faulty components through 2-out-of-3 logic selection or median selection.

Temperature rating: The operating temperature range of electronic devices such as controllers, I/O modules, and power supplies is -30 to 65 ° C (-22 to 149 ° F), with some fieldbus solution modules having slightly reduced operating temperature ranges. During transportation and storage, the temperature range for controllers and other equipment is -40 to 85 ° C (-40 to 185 ° F), while for control room equipment it is 0 to 30 ° C (32 to 86 ° F).

Controller: Compact and flexible design, with multiple frame rate options, different processor speeds, multiple Ethernet, USB, and COM ports, supports simplex, dual, and triple configurations, power supply of 18 to 32V DC, no battery, with status LED, specific cooling method, in compliance with IEC-61508 safety standards, Achilles Level 1 safety certification, operating temperature varies by model, humidity is 5 to 95% non condensing.

Network Security: As a global leader in automation and control, GE regards network security management as an inherent feature of the Mark VIe control series, including network security enhanced control system components, top-notch security features, and software patch services. Security measures include security configuration, secure network architecture (three-layer protection), role-based access control, enhanced control systems, etc. Both controllers and HMI operations have corresponding security protection mechanisms, as well as functions such as security information and event management (SIEM), antivirus patch management, and security patch services.

ControlST software suite

Composition: Includes WorkstationST HMI and history management application, ToolboxST configuration and diagnostic application, and CIMPLICITY graphical tool, suitable for various control applications of GE.

Human Machine Interface (HMI): A Windows based operator station and engineering workstation that can be used as an independent operator station, engineering workstation only, or both, with options for commercial and industrial grade computers. Communication is carried out through Ethernet control networks and separate Ethernet information networks, supporting redundant HMIs and Ethernet networks to improve reliability. Key control and protection functions are processed in the controller, which also performs high-precision time stamping and maintains alarm status.

WorkstationST HMI and Historical Recording Software: Provides a foundation for operator experience, integrates graphical tools, and can manage control system functions such as alarms, events, logs, historical data, networks, and web interfaces. It has functions such as alarm server and viewer, multiple OPC servers, internal and external history recording interfaces, HMI configuration, device manager gateway, Modbus communication, network time protocol (NTP), and user role security system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands