ABB PFEA111/112 Tension Electronic Equipment

ABB PFEA111/112 Tension Electronic Equipment

Product positioning

PFEA111/112 is based on Presductor ® A high-precision tension measurement and control system for technology, used for tension detection and control in the production process of coil materials such as paper, metal strips, and plastic films. Among them, PFEA111 is the basic model, and PFEA112 adds Profibus DP communication function, which is widely used in industries such as papermaking, printing, and metallurgy.

System composition and core technology

1. System composition

Core components: Tension electronic unit (PFEA111/112), weighing sensors (such as PFCL 301E, PFTL 301E, PFRL 101, etc.), junction box (PFXC 141), power module and communication interface (PFEA112 including Profibus DP).

Measurement principle: Based on the magnetostriction effect, the sensor core is a stacked alloy sheet. A 330Hz AC current is passed through the primary winding to generate a magnetic field. The secondary winding induces a voltage signal proportional to the tension due to mechanical force, and has strong resistance to lateral and axial force interference (error ≤± 0.5%).

2. Core Features

Functional differences:

PFEA111: Provides analog output (voltage/current), supports basic tension measurement and control.

PFEA112: Add Profibus DP communication on the basis of PFEA111, supporting remote data transmission and control.

Multi scenario adaptation: Supports single roll (1-2 sensors) and double roll (up to 4 sensors) applications, adapting to multiple types of weighing sensors.

High reliability: equipped with overvoltage, overcurrent, and overtemperature protection, supporting fault self diagnosis, with a protection level of IP20 (DIN rail installation) or IP65 (wall mounted).

Installation and wiring specifications

1. Installation environment requirements

Physical environment: Operating temperature -10~+55 ℃ (IP20), -25~+70 ℃ (IP65), relative humidity ≤ 95% (no condensation), avoid strong electromagnetic interference sources (such as frequency converters).

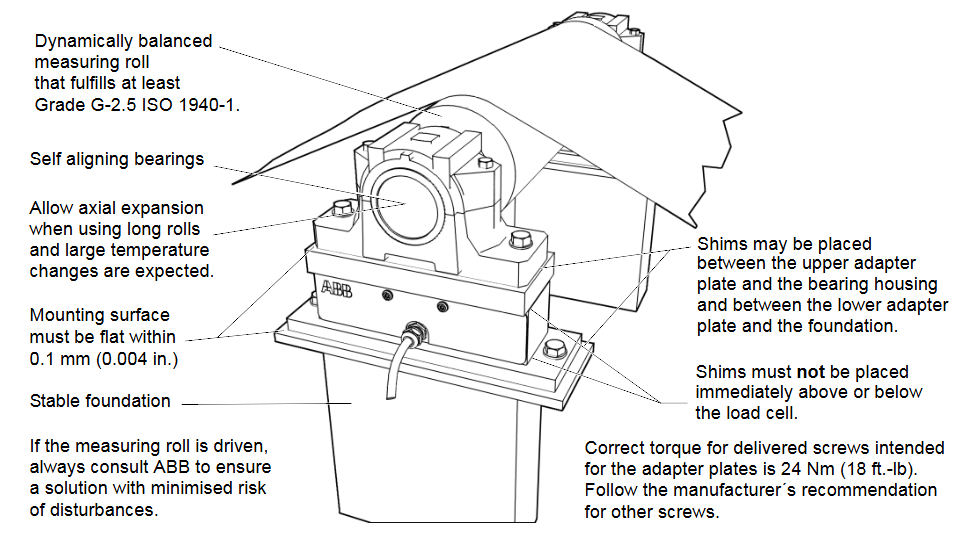

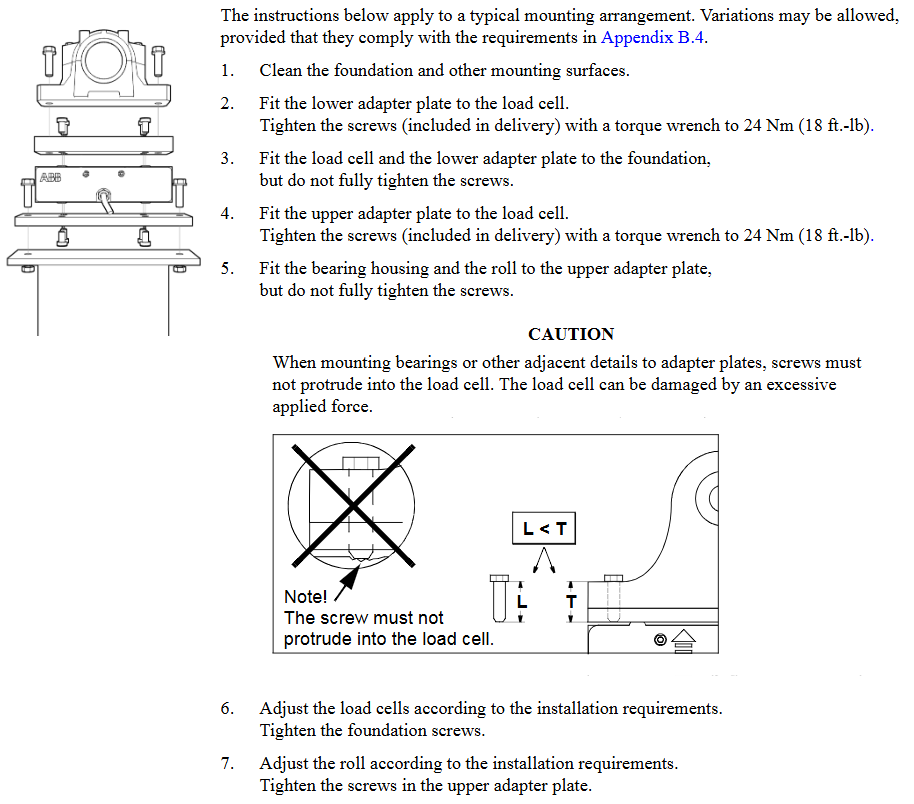

Mechanical requirements: The flatness error of the installation surface should be ≤ 0.1mm, and the gap between the sensor and the adapter board should be clean and free of debris to ensure accurate force transmission.

2. Hardware wiring

Sensor wiring:

The analog signal adopts twisted pair shielded cable, with the shielding layer grounded at one end (length ≤ 50mm) and a distance of ≥ 30cm from the power line.

The maximum allowable cable resistance of the sensor excitation circuit is ≤ 5 Ω, which needs to be measured and confirmed before debugging.

Power and Communication:

The power supply supports wide range input (IP20: 24V DC; IP65: 85-264V AC or 24V DC), with a power consumption of ≤ 8W.

The Profibus DP interface of PFEA112 supports a maximum transmission rate of 12Mbps and requires the use of a dedicated bus cable (impedance 150 Ω) with terminal resistors at both ends.

Debugging and configuration process

1. Basic settings

Quick configuration: Set the language (English/German/French, etc.), unit (N/kN/kg, etc.), and web width (applicable to N/m, etc.) through panel buttons, and support fast zero calibration and wrrap gain calculation.

Complete configuration: including system definition (single roll/double roll), sensor type selection, nominal load setting, zero calibration, and calculation of wrrap gain (derived from suspension weight or formula).

2. Key parameter configuration

Wrap gain: the ratio of tension (T) to sensor measured force (FR), calculated as Wrap gain=T/FR, which needs to be derived through geometric relationships based on the installation angle (horizontal/inclined).

Communication settings (PFEA112): Profibus address (0-125), baud rate (up to 12Mbps), supports real-time data exchange with PLC or SCADA systems.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands