REXROTH EcoDrive Cs series AC servo drive system

REXROTH EcoDrive Cs series AC servo drive system

The EcoDrive Cs series launched by Bosch Rexroth represents an advanced solution for the new generation of system compatible AC servo drive technology in the lower power range (100 to 750 watts). This series is widely used in various automation fields due to its highly compact drive controller and motor design, as well as flexible system integration capabilities. This article is based on the official project planning manual (R911295758 Edition 02), aiming to provide a comprehensive and systematic analysis of the core technology, planning points, and application guidelines of the drive system, offering a unique professional reference for equipment manufacturers, system integrators, and engineering technicians.

1. System Overview and Product Scope

The core of EcoDrive Cs system includes two modules: drive controller and servo motor. The drive controller is exquisitely designed and can be equipped with multiple main communication modules, including its proprietary SERCOS interface, industry standard PROFIBUS-DP, DeviceNet, or CANopen. This allows it to seamlessly integrate into complex systems with multi axis collaborative work, as well as connect to standard fieldbus networks as an independent intelligent single axis module.

In terms of motors, four specifications (100W, 200W, 400W, 750W) are available, and their external dimensions are highly matched with the corresponding drive controllers, achieving optimized space utilization. The motor offers a wide range of optional configurations, such as:

Integrated holding brake: used to lock the shaft position in a power-off state.

Output shaft with keyway: convenient for mechanical connection.

Absolute encoder: It can obtain the current position information of the load without performing a zero return operation, significantly reducing debugging time.

Typical application scenarios include:

Handling and assembly system

packaging machinery

printing equipment

Machine tools

System components can be ordered separately as needed, including motors, basic equipment (drive controllers without main communication cards), main communication cards, absolute encoder batteries, various cables (motors, encoders, RS232), as well as connection and installation accessories, external braking resistors, and power transformers, with highly flexible configurations.

2. Critical safety guidelines

The manual emphasizes the importance of safe operation in a large amount of space, and its warning signs follow the ANSI Z535 standard, divided into three levels: "DANGER", "Warning", and "CAUTION". The core security points include:

2.1 Electrical Safety

High voltage hazard: Contact with live parts exceeding 50V may result in fatal electric shock. All electrical operations must be carried out by qualified personnel, and before operation, ensure that the equipment is completely isolated from the power source and that the capacitors have been fully discharged.

Protective Low Voltage (PELV): All 0-50V terminals must only be connected to circuits and equipment that also comply with PELV safety isolation standards.

Grounding (protective conductor) connection: The equipment casing and all electrical units must be permanently and reliably grounded through a copper safety conductor with a cross-sectional area of not less than 10 mm ² to dissipate leakage current (which may exceed 3.5mA during normal operation).

2.2 Preventing dangerous movements

The drive system may experience unexpected dangerous movements due to wiring errors, improper parameter settings, component failures, or software errors. The integrated monitoring function is not sufficient to ensure absolute personal safety, and higher-level measures must be taken:

Isolate hazardous areas through physical barriers such as safety fences, protective covers, and light curtains.

The emergency stop switch must be installed within reach of the operator and its function must be tested and verified.

After the motor power is cut off, the vertical axis needs to be additionally prevented from falling through mechanical locking, external braking/capturing devices, or sufficient weighting. The built-in holding brake of the motor or the external brake directly controlled by the driver is not sufficient to ensure personal safety.

2.3 Protection against other hazards

Magnetic and electromagnetic fields: pose a health risk to individuals wearing pacemakers, metal implants, or hearing aids, and should be prohibited from entering areas where equipment is installed, operated, or stored.

High temperature components: The equipment casing (especially near the heat sink) and resistors may become extremely hot during operation. After shutdown, it is necessary to wait for at least 10 minutes for them to cool down before coming into contact.

Battery safety: Do not attempt to charge, put into fire, or disassemble discharged batteries. Environmental protection treatment must be carried out in accordance with local regulations.

Pressure system: an external supply system involving compressed air, hydraulic oil, etc., which must release pressure and empty the medium before disassembly.

3. Detailed explanation of driving controller technical data

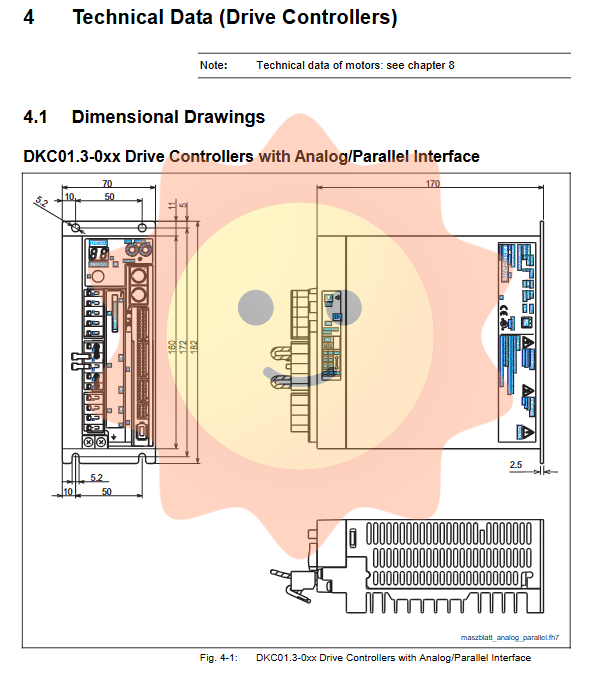

3.1 Mechanical and Environmental Data

The drive controller is designed specifically for installation in control cabinets, with a protection level of IP20. Its rated data environmental conditions are: ambient temperature from 0 to+40 ° C, installation altitude ≤ 1000 meters. The maximum allowable ambient temperature can reach+55 ° C (requiring derating operation), with a maximum installation altitude of 2000 meters. The storage and transportation temperature range is -20 to+80 ° C. Attention should be paid to natural convection cooling, and the longitudinal axis should be consistent with the convection direction during installation. The back should be in full contact with the installation plate and maintain a minimum distance from other components (40mm above, 10mm on the side, and 100mm below).

3.2 Electrical and Performance Data

The power input supports single-phase (1 x 200-240V AC) or three-phase (3 x 200-240V AC) connections. For 750W equipment, three-phase connection is strongly recommended as single-phase operation can significantly shorten the service life and lead to performance degradation.

The manual provides detailed input/output current, power loss, DC bus data, and internal braking resistor parameters. The key "derating" information clearly states that the continuous output capability of the driver and motor needs to decrease according to the curve under the following conditions:

Installation at an altitude exceeding 1000 meters.

The ambient temperature exceeds 40 ° C (with a decrease of approximately 2% for every 1 ° C increase).

Use internal braking resistors (only applicable to 200W and 400W models). At this point, full power can be restored by removing and connecting external braking resistors through jumper wires.

The 750W model uses single-phase power supply.

The control voltage (L1C/L2C of X1 interface) is also 200-240V AC, which is converted internally by the driver to the required voltage. The front panel includes a diagnostic display (H1), a reset/function button (S1), and two ten digit dip switches (S2, S3) for setting the driver address (1-99).

4. Depth analysis of electrical connections

4.1 General Interface Description

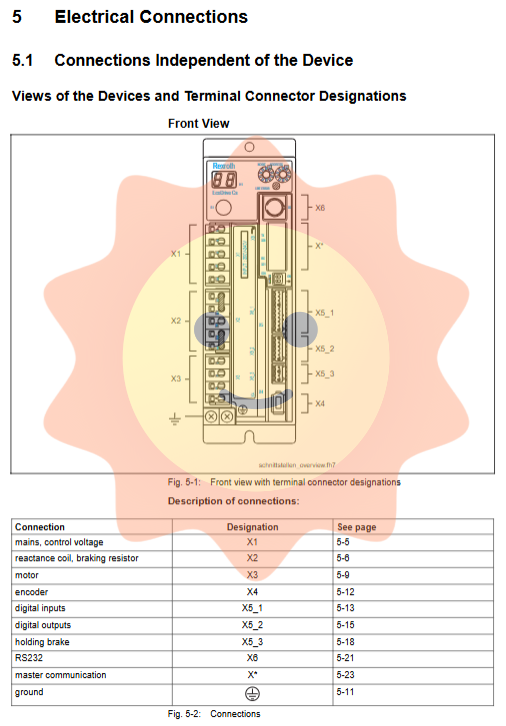

All models have the following core interfaces (X1 to X6):

X1 (Power and Control Voltage): Connect the main power supply (L1, L2, L3) and control voltage (L1C, L2C). The connection must use 0.75-2 mm ² twisted wire.

X2 (additional reactor and braking resistor): Connecting an external reactor can increase the power of the continuous DC bus; Connecting external braking resistors (RB1, RB2) can avoid derating when using internal resistors. If external resistors are not used, RB2 and RB3 must be short circuited with jumper wires.

X3 (motor connection): Connect servo motors (U, V, W, PE). It is necessary to use Rexroth original motor cables or certified cables, with a maximum length of 40 meters, otherwise it may result in the system warranty being invalidated.

X4 (Encoder): Provides power (5V, 0V) and signal (PS+/PS -) interfaces for the motor encoder, and includes terminals for backup batteries (if used) for the absolute encoder.

X5_1/X5_2 (digital input/output): Provides 7 configurable digital inputs and 3 configurable digital outputs (including a pair of "ready to run" relay contacts Bb). Both input and output are optocoupler isolated.

X5_3 (holding brake): Control the motor brake (BR+/BR -) and provide its external 24V power input. The brake power supply must be supplied externally, and the brake power supply of multiple drivers should be connected in a star topology, and serial connection is prohibited.

X6 (RS232): Used for debugging, parameter setting, and diagnosis through PC software (such as DriveTop). Only supports point-to-point connections, with a maximum distance of 15 meters.

4.2 Equipment related interfaces

According to the selected basic device (DKC10.3 series) and the inserted Master Communication Card, different terminal device models are formed:

DKC01.3: Analog/Parallel Interface. Additional X5_4 (analog/digital I/O) and X7 (incremental/absolute encoder simulation output) interfaces are provided.

DKC02.3: Integrated SERCOS interface. Connected through fiber optic cables, the front panel dip switch can adjust the light emission power to accommodate different lengths of optical fibers (plastic fiber up to 50 meters, glass fiber up to 500 meters).

DKC03.3: Provide PROFIBUS-DP interface (9-pin D-Sub) by inserting ECM01.1-PB01 card.

DKC06.3/DKC16.3: Provides DeviceNet interface by inserting ECM01.1-DN01 or ECM01.1-DN02 card, with the difference being the connector type (COMBICON or sealed micro).

DKC05.3: Provide CANopen interface (9-pin D-Sub) by inserting ECM01.1-CN01 card.

The main communication card can be installed or replaced on site, and the operation needs to be carried out after power failure.

5. Key points of power connection and control cabinet design

5.1 Main power connection

The driver must be permanently connected to the power grid. When the grid voltage is higher than 240V, an autotransformer or isolation transformer must be used for voltage reduction. The manual provides detailed calculations of surge characteristics and grid side phase currents for different types of equipment, and guides the selection of main contactors (K1) and fuses (Q1) accordingly. To reduce the total surge current caused by multiple drivers being powered on simultaneously, SUP-E05-DKC * CS-SURGEP accessories (including NTC thermistor) can be selected for 100W/200W/400W devices. For 400W equipment, the maximum load power when using this accessory should be limited to 70%.

5.2 Control Circuit and Safety Interlocking

The "Ready to Run" (Bb) relay contact (normally open) output by the driver is a prerequisite for controlling the main contactor to close. This contact opens when there is a loss of control voltage, emergency stop activation, or driver failure. The emergency stop signal should be directly applied to the enable circuit and should not be removed from behind the Bb contact. When designing an emergency stop circuit, it is necessary to consider the series connection of all drive Bb contacts, as well as the load capacity and power-off delay of the contactors.

5.3 Control Cabinet Planning

Heat dissipation and layout: The total heat generation inside the control cabinet must be calculated to ensure that the inlet air temperature does not exceed the allowable value of the driver. Cooling units can be used, but attention should be paid to preventing condensed water droplets from falling or splashing onto electronic devices, and the temperature should be set reasonably to avoid condensation caused by the temperature inside the cabinet being lower than the ambient temperature.

Wiring specifications: Strong current (power supply, motor wires) and weak current (signal, encoder wires) should be laid separately, with a minimum distance of 100mm or separated by metal partitions. The recommended layout of cable trays helps optimize electromagnetic compatibility (EMC).

EMC measures: To meet electromagnetic compatibility requirements, recommended main power filters (such as NFE/NFD series) should be used, and the folding ferrite core in the attachment (installed near the interface) should be used for signal lines.

6. In depth analysis of MSM series servo motors

The motor offers four frame sizes: MSM020B (100W), MSM030B (200W), MSM030C (400W), and MSM040B (750W), each with/without a brake, incremental/absolute encoder, and optical axis/keyway combination.

6.1 Key Technical Parameters

Thermal performance and working system: The motor data is based on an ambient temperature of 40 ° C and a winding temperature rise of 80K (enclosure IP65). Following the S1 (continuous working system) or S6 (intermittent working system) standards of EN 60034-1, key parameters such as continuous stall torque (Mdn), peak torque (Mmax), and rated speed (nN) are defined.

Shaft and bearing loads: The manual provides detailed allowable radial and axial force data. The rated life of the bearing L10h is 20000 hours when the load does not exceed the limit. Exceeding the radial force will shorten the bearing life in a cubic relationship.

Protection level and installation: The protection level of the motor body is IP65 (when the cable joint is correctly installed), and the shaft extension is IP40. The allowed installation positions include flange installation (IM B5) and shaft extension facing downwards (IM V1) or upwards (IM V3). Tighten the installation screws with the specified torque.

6.2 Encoder System

Incremental encoder: Provides 2500 sine wave signals per revolution (multiplied by 4 to 10000 pulses) with zero marks. Location information lost after power outage.

Absolute encoder: Single cycle resolution of 17 bits (131072 pulses/rev), multi cycle range of 16 bits (65536 cycles). It is necessary to rely on the backup battery inside the drive (Attachment SUP-E03-DKC * CS-BATTY) to maintain multiple cycles of data during power outages. When the battery level is low, the driver will report fault F248. The battery life is positively correlated with the power on time of the drive, and battery replacement needs to be completed within a limited backup time (about 13 minutes for a new battery).

6.3 Maintain the brake

It is of the "power-off clamping" type. Control its on/off timing by the driver. Important note: This brake is designed for static holding, not dynamic braking. Frequent use of shafts in braking motion can lead to premature wear (with a designed lifespan of approximately 3000 motor revolutions in the closed state). Personnel safety cannot rely solely on motor brakes.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA