REXROTH IndraControl VEP Embedded Terminal Project Planning and Operation Guide

REXROTH IndraControl VEP Embedded Terminal Project Planning and Operation Guide

1. Product Overview and System Introduction

The IndraControl VEP series is a PC based machine operator terminal launched by Bosch Rexroth, suitable for monitoring, operation, and control tasks in industrial automation environments. This series includes three models: VEP 30.2, VEP 40.2, and VEP 50.2, which differ mainly in display screen size, operation mode, and interface configuration. All models adopt a unified PC box design, support PC104 expansion slots, and have good compatibility and expandability.

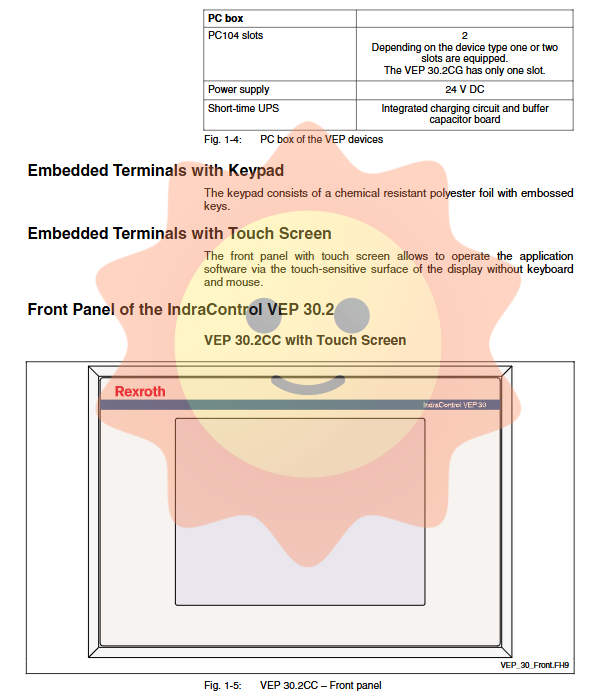

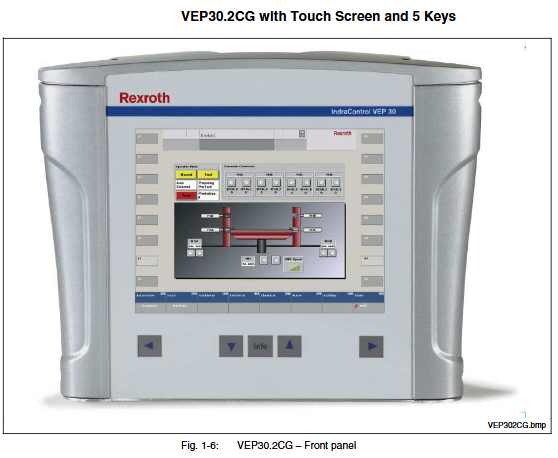

VEP 30.2 offers an 8.4-inch TFT touch screen, divided into a pure touch screen version (CC) and a version with a 5-key keyboard (CG). VEP 40.2 is equipped with a 12.1-inch touch screen, while VEP 50.2 is equipped with a 15 inch touch screen, both of which are purely touch operated. All front panels are designed in RAL 7035 light gray with a protection level of IP65 (VEP 30.2CG is IP40), suitable for environments with high hygiene requirements such as the food industry.

The device is equipped with an Intel Ultra Low Voltage Celeron 400MHz processor, 128MB memory and 128MB CompactFlash card, pre installed with Microsoft Windows CE. NET 4.2 embedded operating system, and integrated with IndraLogicWinCE soft PLC and WinStudio visual operating environment. Its 24VDC power supply has a wide input range (+19V to+30V), built-in buffer capacitor group, supports short-term UPS function, and ensures stable operation of the system under power fluctuations.

2. Technical specifications and hardware interfaces

2.1 Display and Operation Unit

VEP 30.2: 8.4-inch TFT, 800 × 600 pixels, 262K colors, touchscreen (CC type) or touch+5 key (CG type).

VEP 40.2: 12.1-inch TFT, 800 × 600 pixels, 262K colors, pure touch operation.

VEP 50.2: 15 inch TFT, 1024 × 768 pixels, 262K colors, pure touch operation.

The backlight system has an automatic dimming function, which can reduce the brightness to 50% after 5 minutes of inactivity to extend its lifespan. The lifespan of a display screen varies depending on its size: 8.4 inches for approximately 20000 hours, 12.1 inches for approximately 40000 hours, and 15 inches for approximately 30000 hours.

2.2 Core Hardware Configuration

Processor: Intel Celeron 400MHz, integrated graphics card (shared memory of approximately 8MB).

Memory: 128MB RAM, 128MB CompactFlash.

Expansion slots: up to 2 PC104 slots (VEP 30.2CG only 1).

Protection level: PC box IP20, front panel IP65 (CG type IP40).

2.3 Interface Overview

The equipment comes standard with the following interfaces:

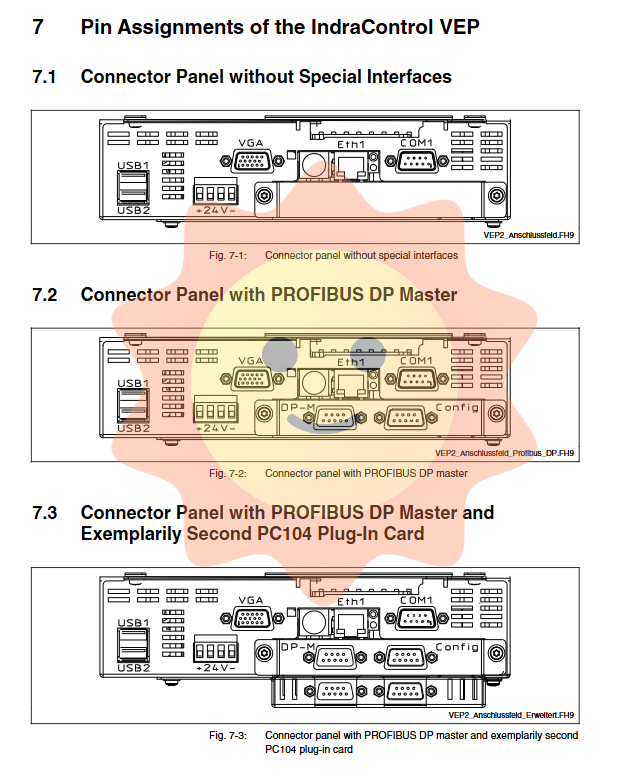

1 x VGA external display interface (15 pin HD Sub)

2 x USB 1.1 interface (Type A)

1 x Ethernet interface (RJ45, 10/100Base-T)

1 x keyboard/mouse PS/2 interface

1 × RS232 serial interface (9-pin D-Sub)

24VDC power interface (Weidm ü ller connector, 4-pin)

The optional configuration includes a PROFIBUS DP master interface (9-pin D-Sub), supporting a maximum communication speed of 12Mbps, and comes with an RS232C diagnostic interface.

3. Safety usage regulations and electrical protection

3.1 Applicable and Not Applicable Scenarios

IndraControl VEP is designed for industrial control environments, with typical applications including handling and assembly systems, packaging and food machinery, printing and papermaking equipment, machine tools, and more. The equipment is only allowed to be used under the installation and environmental conditions (temperature, humidity, protection level, EMC, etc.) specified in the document.

It is strictly prohibited to use it in the following scenarios:

Not meeting environmental conditions (such as water, extreme temperature environment)

Special applications not explicitly approved by Bosch Rexroth

Control of protective equipment related to personal safety

3.2 Electrical safety measures

High voltage protection: All electrical components above 50V must be operated by professionals, the equipment must be reliably grounded, and copper protective wires with a cross-sectional area of not less than 10mm ² must be used.

Low voltage protection (PELV): 0-50V terminals must be connected to circuits that comply with PELV standards to ensure safe isolation from high voltage circuits.

Leakage current protection: During normal operation, the leakage current may exceed 3.5mA, so the use of residual current devices (RCD) is prohibited. Indirect contact protection should be achieved through overcurrent protection devices.

3.3 Mechanical Motion and Hazard Protection

Dangerous movement protection: It is necessary to prevent personnel from entering the range of equipment movement through higher-level monitoring equipment, safety fences, light curtains, and other measures.

Emergency stop: The emergency stop button must be installed in a location easily accessible to the operator, and its function must be verified before starting.

Vertical axis safety: After power failure, mechanical locking, external braking, and other methods must be used to prevent the axis from falling.

3.4 Electromagnetic Fields and Thermal Protection

Electromagnetic sensitive personnel: Personnel wearing pacemakers, metal implants, or hearing aids must not approach operating electrical equipment or permanent magnet motors.

High temperature surface: The casing of the equipment may be at high temperature during operation, and it needs to be cooled for at least 10 minutes after power failure before it can be touched.

3.5 Battery and Pressure System Safety

CMOS battery: Provides power for BIOS real-time clock, with a lifespan of approximately 5 years. Replacement requires contacting authorized services.

Capacitor group: As a component of UPS, its lifespan is affected by environmental temperature, and it is recommended to replace it every 5 years.

Pressure system: It is prohibited to disassemble pipelines under pressure. The pressure must be released and the medium must be emptied first.

4. Installation dimensions and mechanical installation

4.1 External dimensions

VEP 30.2CC: Front panel 296mm × 200mm

VEP 30.2CG: Overall 306mm × 241mm, with bracket mounting holes

VEP 40.2CE: Front panel 350mm × 290mm

VEP 50.2CH: Front panel 407mm × 370mm

4.2 Installation Guide

Drill holes (with a diameter of 5mm) on the installation panel according to the drawing.

Insert the device into the opening from the front and insert the M4 mounting bolt.

Tighten the nut from the back to secure it.

Ensure that at least 50mm of space is reserved around the device for heat dissipation and wiring.

Avoid direct sunlight to avoid affecting screen visibility and heat dissipation.

4.3 Expansion card installation

The device supports a second PC104 expansion card, which requires replacing the back cover and increasing the installation depth by 11mm. Only expansion cards released by Bosch Rexroth are allowed to be used.

5. Software system and initial debugging

5.1 Operating System and Pre installed Software

The device comes pre installed with Windows CE. NET 4.2 and integrates the following software environments:

IndraLogicWinCE: A soft PLC that complies with IEC 61131-3 and requires license activation.

WinStudio "lite": Visualization runtime, limited functionality, can be upgraded to a fully functional version.

Configuration tool: Rexroth CE Settings is used for network, auto start, server, and other settings.

5.2 First Power On and Touch Calibration

When powered on for the first time, the system automatically enters the touch calibration interface, and the user needs to use a stylus to click on four calibration points in sequence. After calibration is completed, it automatically enters the Rexroth CE Settings configuration interface. If calibration is incorrect, the boot.boo file in the root directory of the CompactFlash card can be deleted to restore factory settings.

5.3 Network and Communication Configuration

Configurable through Rexroth CE Settings:

Ethernet adapter: supports DHCP automatic acquisition or manual setting of IP, subnet mask, gateway DNS。

Application settings: Select the visualization data source (serial port or Ethernet), automatically launch programs (such as WinStudio, Remote Desktop, web browser, etc.).

Server settings: Enable/disable built-in FTP, web, Telnet servers.

5.4 USB device support

The system only supports tested USB devices, including:

Keyboard: HP KU-0133, Logitech Internet Navigator, Cherry G81-3000, etc

Mouse: IBM MO09BO, Cherry M-5000, Microsoft Basic Optical Mouse

USB flash drive: MC OSFLASHUB-064M released by Bosch Rexroth

6. Maintenance and upkeep

6.1 Daily Cleaning

Use anti-static cloth or window cleaner containing denatured alcohol to wipe the screen every week.

It is strictly prohibited to use solvents (such as paint thinner) to clean the keyboard film and display screen sealing strip.

6.2 Regular Inspection

Check all connectors and terminals for tightness and cables for damage every year.

Check the operation status of the fan and be careful not to place fingers or foreign objects near the fan blades.

6.3 Replacement of vulnerable parts

Backlight: When the brightness drops to 50%, it needs to be replaced. Contact authorized service.

CMOS battery: approximately 5 years lifespan, replacement requires professional service.

Capacitor group: It is recommended to replace it every 5 years, especially in high temperature environments.

7. Ordering Information and Accessories

7.1 Model Code

The device model code includes information such as display screen type, operation mode, interface configuration, etc. Please refer to Chapter 10 of the document for details. Users can choose models with configurations such as PROFIBUS DP and expansion slots according to their needs.

7.2 Attachments and Storage Media

Connecting cables: prefabricated PROFIBUS cables (such as IKB0033/000.0), power and signal lines.

Storage media: 64MB/128MB CompactFlash module, 64MB USB flash drive (MC OSFLASHUSB-064M).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA