REXRTOH DIAX04 Second Generation Driver Controller Application Guide

REXRTOH DIAX04 Second Generation HDD and HDS Driver Controller: Technical Analysis and Application Guide

Introduction

In the field of industrial automation and motion control, the performance and reliability of the drive controller, as the core execution unit, directly affect the operational efficiency and accuracy of the entire system. The DIAX04 second-generation HDD and HDS drive controller launched by Rexroth Indramat has become the preferred choice for many high-precision motion control systems due to its modular design, high-performance interface, and wide application adaptability. This article is based on the technical manual "DIAX04 HDD and HDS Drive Controllers 2nd Generation Project Planning Manual", which systematically outlines its technical architecture, safety specifications, electrical connections, installation points, and maintenance support, providing a comprehensive application guide for engineering and technical personnel.

System Overview and Composition Architecture

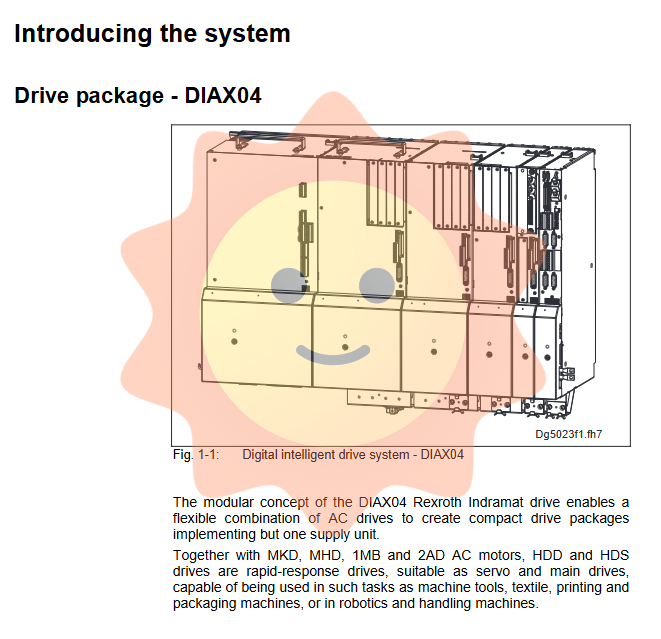

The DIAX04 system adopts a modular design concept, integrating the AC drive system into a compact drive package, which can achieve multi axis coordinated control through only one power unit. This system supports the use of MKD, MHD, 1MB, and 2AD series AC motors, and is suitable for servo and spindle drive scenarios. It is widely used in high dynamic response scenarios such as machine tools, textile machinery, printing equipment, packaging machinery, robots, and handling systems.

The main components of the system include:

Drive controller: divided into two types: HDD (dual axis fixed configuration) and HDS (configurable multi axis);

Power supply unit: such as HVE or HVR power module, providing signals and power voltage to the controller;

Additional modules: such as braking resistor HZB, capacitor module HZK, power connection module HZF, etc., used to enhance the system's energy processing capability;

Motor and feedback system: including various AC motors, encoders, and temperature monitoring devices.

Safety regulations and usage guidance

Safety is the primary principle in the design and operation of industrial equipment. The manual provides detailed safety instructions for electrical servo drive and control systems, covering the following aspects:

1. Electrical safety

High voltage protection: All electrical components above 50V must be operated by professionals after power failure, and the grounding wire must be permanently connected;

Leakage current management: Equipment leakage current may exceed 3.5mA, and copper protective wires with a cross-sectional area of not less than 10mm ² must be used;

PELV protection: All 5-50V terminals comply with the protection ultra-low voltage standard and must be connected to a safety isolated electrical circuit.

2. Sports safety

Dangerous motion protection: The driver may accidentally move due to control failures, sensor errors, or software abnormalities, and must be protected by higher-level monitoring systems or mechanical protective devices (such as guardrails, light curtains, emergency stop buttons);

Vertical axis anti fall: After power failure, the vertical axis needs to be prevented from falling through mechanical locking, external braking, or counterweight.

3. Environment and personnel safety

Electromagnetic field protection: The magnetic field generated by the motor and current carrying conductor may pose a health risk to the wearer of pacemakers, metal implants, or hearing aids, and access to relevant areas should be restricted;

Hot surface protection: During equipment operation, the casing, heat sink, and other components may experience high temperatures and need to be cooled before coming into contact;

Battery and pressure system safety: The battery must not be charged or disassembled, and the pressure system must be operated by professionals and handled properly with the working medium.

4. Usage guidelines

Applicable scenarios: Suitable for industrial automation fields such as machine tools, packaging, printing, and handling;

Prohibited use: including unverified applications such as construction cranes, manned elevators, medical equipment, explosion-proof areas, etc;

Environmental conditions: The working temperature range is+5 ° C to+45 ° C, the installation altitude does not exceed 1000 meters, and the protection level is IP10.

Driver controller configuration and modular design

The DIAX04 driver controller adopts a highly modular structure, and the basic unit is customized by inserting different functional modules for configuration. A fully configured drive includes:

Basic Unit: Provide power interface and mechanical structure;

Instruction communication module: such as SERCOS interface module DSS02.1M or analog interface module DAE02.1M;

Software module (HSM): stores firmware and driver parameters, supports hot swappable replacement;

Additional plugin module:

Digital I/O card (DEA series): supports PLC data exchange;

Measurement system interface cards (DEF, DLF, DRF, etc.): support incremental encoders, sine signal encoders, absolute value encoders, etc;

Communication cards (DAK, DAQ): support ARCNET and multi master synchronization links;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA