REXRTOH IndraDrive Controller CS Series Technical Analysis and Application Guide

IndraDrive Controller CS Series: Technical Architecture, Configuration, and Application Analysis

The IndraDrive series drive controller launched by Bosch Rexroth, as a representative of high-performance servo drive solutions in the field of industrial automation, is widely used in high-precision motion control scenarios such as packaging machinery, printing equipment, machine tools, and robots due to its flexible configuration, rich interfaces, and strong scalability in the control section, especially the CSB01, CSH01, and CDB01 series. This article is based on the official Project Planning Manual (R911295012-Edition 09) and provides a comprehensive review and technical interpretation of the IndraDrive control section from the aspects of system architecture, model classification, functional interfaces, optional modules, safety specifications, and technical data. The aim is to provide engineers and system planners with a clear and detailed set of integration guidelines.

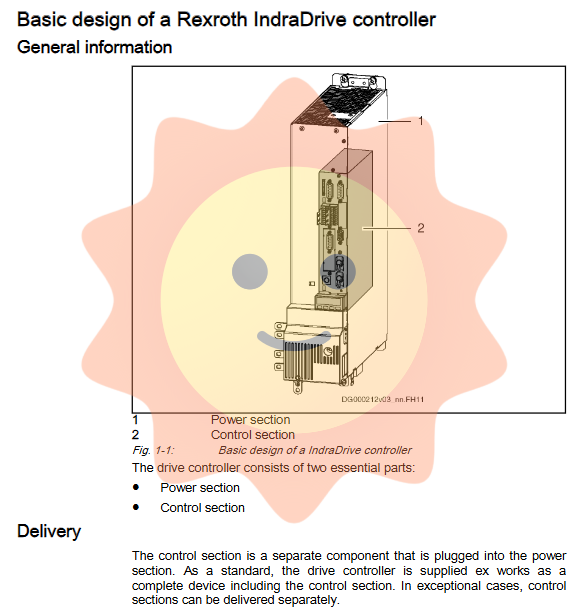

IndraDrive system architecture and basic concepts of control segments

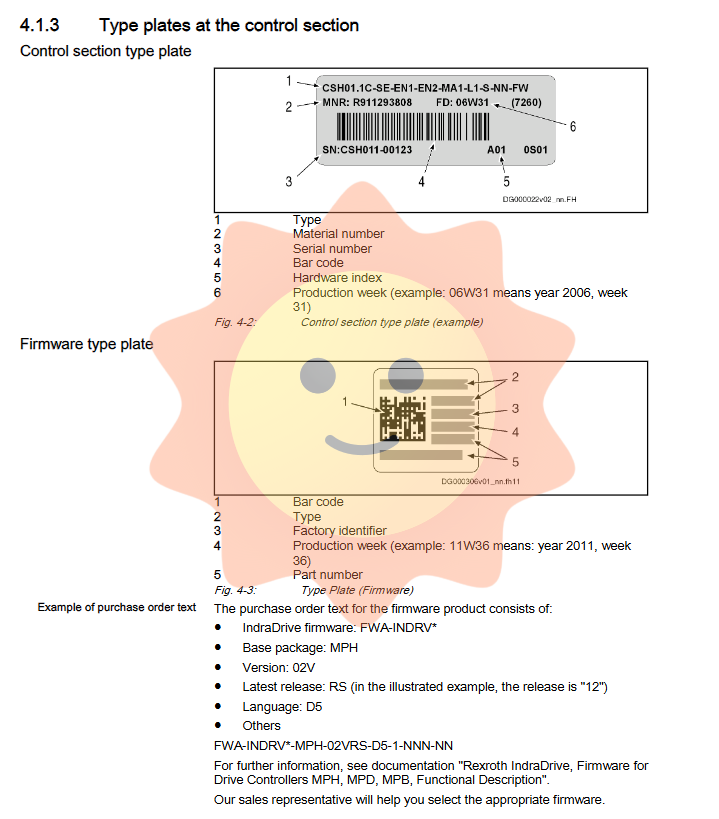

The IndraDrive drive controller consists of two core components: the Power Section and the Control Section. The control section serves as the "brain" of the driver, responsible for executing motion control algorithms, external communication, signal acquisition, and safety monitoring functions, and is connected to the power section in a plug-in manner. According to the manual, standard factory equipment is usually in a fully assembled state, and the control section can also be delivered separately, making it convenient for users to upgrade or replace according to project requirements.

When installing and disassembling the control section, the following specifications must be strictly followed:

Only personnel trained in Rexroth are allowed to operate;

ESD protection measures must be taken, such as grounding operators and tools;

The maximum number of control segment insertions and removals is 20 times to avoid interface wear and affect reliability.

Classification and core characteristics of control segment models

The IndraDrive control section is mainly divided into two series: BASIC and ADVANCED, further subdivided into single axis and dual axis configurations to adapt to different motion control complexities and cost requirements.

1. BASIC series control segment

The BASIC series includes BASIC OPENLOOP(FC)、BASIC SERCOS(SE)、BASIC PROFIBUS(PB)、BASIC ANALOG(AN) And various models such as BASIC UNIVERSAL (configurable). among which

CSB01.1N-FC: Suitable for open-loop control, with 8 digital inputs, 2 analog inputs/outputs, and relay outputs;

CSB01.1N-SE: Integrated Sercos fiber optic communication interface, supporting high-speed periodic communication;

CSB01.1C: It is a configurable single axis control segment that supports multiple communication and encoder options;

CDB01.1C: It is a configurable dual axis control section that can independently control two servo axes, suitable for compact multi axis systems.

The typical control cycle of BASIC series is 125 µ s for current loop, 250 µ s for speed loop, and 500 µ s for position loop. The switching frequency supports 2 kHz, 4 kHz, and 8 kHz (some models can reach 12-16 kHz).

2. ADVANCED series control section

The ADVANCED series (CSH01.1C/2C/3C) is designed for high-performance applications, featuring shorter control cycles (current loops up to 62.5 µ s) and stronger computational capabilities, supporting more complex multi axis coordination and safety functions. Its characteristics include:

More diverse digital and analog I/O (up to 22 digital inputs and 4 analog outputs);

Integrated Engineering Interface (X26), supporting Ethernet based debugging and diagnostics;

Optional cross communication module (CCD) is available to achieve direct data exchange between drivers.

Optional modules and system extensions

The IndraDrive control section provides a wide range of optional modules, and users can flexibly expand its functions through slots (such as X4, X8, X41, etc.), mainly including the following categories:

1. Communication module

Sercos (SE): Based on fiber optics, it has strong anti-interference ability and is suitable for high-speed real-time networks;

PROFIBUS (PB): Supports DP protocol and is widely used in factory automation;

Multi Ethernet (ET): integrates multiple Ethernet protocols (Sercos III, EtherCAT, Profinet, etc.);

CANopen/DeviceNet (CO/CD): suitable for distributed I/O and device networking;

Parallel Interface (PL): Provides 16 digital inputs/outputs, suitable for high-speed pulse control.

2. Encoder evaluation module

ENS: Supports IndraDyn and HIPERFACE ®、 EnDat 2.1, 1 Vpp sine and 5V TTL encoder;

EN1: Suitable for Resolvers and HSF digital servo feedback;

EN2: Supports 5V encoder with Sense line feedback, which can compensate for cable voltage drop.

3. I/O expansion module

AN: Add 4 differential analog inputs (± 10 V);

MA1: Provides 2 analog inputs and 2 analog outputs with an accuracy of 12 bits;

MD1/MD2: Expand the number of digital input and output points, and MD2 also integrates the SSI absolute value encoder interface.

4. Security technology module

L1: Start lock stop (compliant with EN60204-1 stop category 0);

L2: Safe Torque Off;

S1/S2: Supports safety functions such as Safe Motion, safe speed limit, and safe position that comply with IEC 61508.

Electrical Connection and Signal Specification

The electrical interfaces of the control section mainly include:

X31/X32: Digital and analog I/O, 24V power input;

X2: RS232 serial port, used for debugging and parameter setting;

X26: Engineering Ethernet interface, supporting web diagnostics and software updates.

There are four types of digital inputs:

Type A (standard): compliant with IEC 61131, response time 20-100 µ s;

Type B/C (probe input): used for high-speed position capture, with pulse widths supporting 4 µ s and 200 µ s respectively;

Type D: Can be reused with analog input.

Analog input supports ± 10 V voltage or 0-20 mA current signals, with a resolution of 12 bits and a maximum common mode rejection ratio of 70 dB. Analog output provides 0-10 V or ± 10 V signals, with a load capacity of 5 mA-10 mA.

Safety regulations and usage precautions

The IndraDrive control system design complies with multiple international safety standards, and the manual specifically emphasizes:

Safe voltage (PELV): All interfaces ≤ 50 V comply with the protection ultra-low voltage standard and can be connected to basic insulation equipment;

Grounding requirements: When the leakage current is greater than 3.5 mA, a suitable ground wire should be selected according to the cross-sectional area of the wire (see Table 3-1 in the manual for details);

Dangerous sports protection: measures such as external safety barriers, emergency stop switches, and mechanical brakes must be taken to prevent accidental movements;

Thermal protection: Surface temperatures of heat sinks, braking resistors, etc. may exceed 60 ° C, and protective covers or warning signs should be installed;

Electromagnetic compatibility: The drive controller belongs to Class C3 equipment in IEC 61800-3 and requires filtering and shielding measures. It is not suitable for civilian low-voltage power grids.

Environmental protection, disposal, and service support

Environmental protection features: The main body of the product is made of metal and plastic, with a focus on resource recycling during the production process, and does not contain harmful substances;

Scrap disposal: Users can send the cleaned products back to Rexroth for professional recycling, and the batteries need to be disposed of separately according to local regulations;

Service Network: Rexroth provides global technical support, with a technical capability center at its headquarters in Germany and a 24/7 service hotline at+49 9352 40 5060.

Model Supplement

1、 Main model of Control Sections

1. BASIC series

CSB01.1N-FC (Basic 1, OPENLOOP)

CSB01.1N-SE (Basic 2, SERCOS)

CSB01.1N-PB (Basic 3, PROFIBUS)

CSB01.1N-AN (Basic 4, ANALOG)

CSB01.1C (Basic 5, BASIC UNIVERSAL single axis)

CDB01.1C (BASIC UNIVERSAL Dual Axis)

2. ADVANCED series

CSH01.1C

CSH01.2C

CSH01.3C

2、 Optional Modules

1. Communication module

AN: Analog input extension (also used as a communication method for CSB01.1N-AN)

SE: Sercos (HCC02)

PB: PROFIBUS (HCC03)

PL: Parallel Interface (HCC01)

CO: DeviceNet/CANopen (HCC06, spring terminal)

CD: DeviceNet/CANopen (D-Sub interface)

S3: Sercos III “Slave” (HCC07)

ET: Multi-Ethernet (HCC20)

CCD: Cross Communication "Master" (HMC01)

2. Encoder Evaluations

ENS: Standard Encoder Evaluation (IndraDyn, HIPERFACE) ®, 1Vpp, 5V TTL)

EN1: Evaluation of Resolvers and HSF Encoders

EN2: EnDat 2.1/1Vess/TTL Encoder Evaluation

3. I/O expansion

AN: Analog input extension (4-channel differential)

MA1: Analog I/O Expansion (2 in 2 out, 12 bit)

MD1: Digital I/O Expansion (12 in, 8 out)

MD2: Digital I/O Expansion and SSI Encoder Evaluation (16 in, 16 out)

4. Safety Technology

L1: Starting Lockout

L2: Safe Torque Off

S1: Safety Technology I/O

S2: Safe Motion

5. Other

S: Standard Control Panel

PFM02.1: MultiMediaCard memory card (including FW and NW variants)

MEM: Encoder Simulation Module

3、 Related motor series models (mentioned in the document overview section)

MAD/MAF (Asynchronous Motor)

MBS-H (Synchronous Sleeve Spindle Motor)

MLF (Synchronous Linear Motor)

MCL (Ironless Linear Motor)

MKE (Explosion proof Synchronous Servo Motor)

MSK (Synchronous Servo Motor)

MS2E (ATEX explosion-proof synchronous servo motor)

MS2N (synchronous servo motor)

MBT (Synchronous Torque Motor)

MSM (Synchronous Servo Motor)

MHD (mentioned in the document, used for HSF encoder)

MKD (mentioned in the document, used for Resolvers)

4、 Connecting cables and accessory models (examples mentioned in the document)

RKB0021 (Long distance Ethernet cable, replacing RKB0011)

RKB0013 (Ethernet cable inside short distance control cabinet)

RK80021 (long-distance Sercos III/Ethernet cable)

RK80013 (Short distance Sercos III/Ethernet cable)

RKG4200 (connected to S1/M1 encoder system)

RKG0014 (connected to C0 encoder system)

IKS4043 (connected to R0/R1 encoder system)

IKS4042 (connected to SO/MO encoder system and SHL Hall sensor box)

IKS4038 (connected to a third-party 5V encoder)

RKG4400 (SSI encoder connected to MD2)

RKG4401 (compatible with Stegmann SSI encoder)

RKS0004 (X17 I/O expansion port connected to MD2)

RKS0003 (Connect MA1 simulation module to distribution box)

RKS0001 (Single core wire connection for safety module)

HAS051-003 (Encoder Simulation Signal Level Converter)

HAS051-005 (RS232/RS485 Signal Level Converter)

HAS051-007 (D-Sub to terminal block adapter, including NNR/NNL variants)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA