GE FANUC S2K series independent motion controller

FANUC S2K series independent motion controller

Equipment Overview

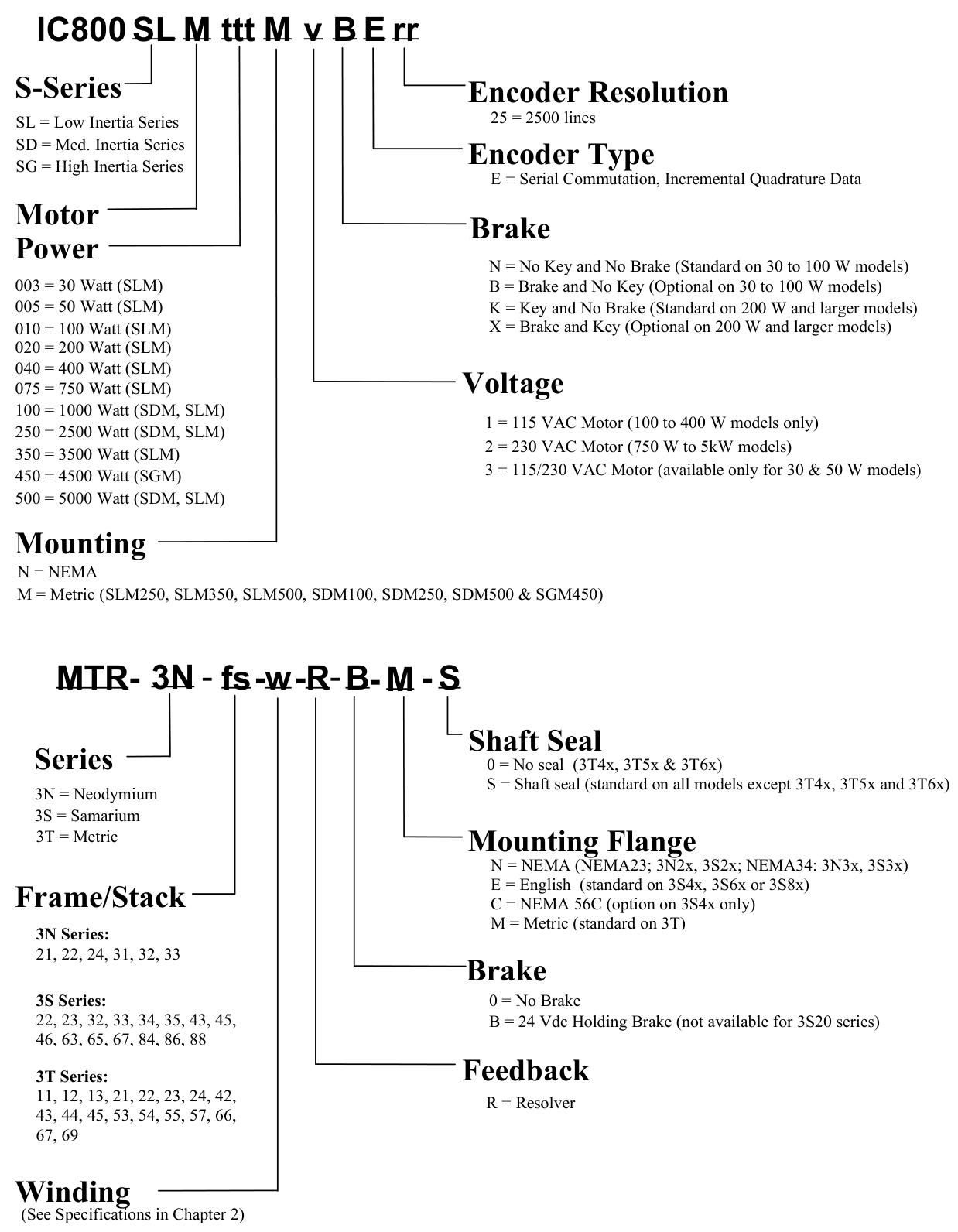

The FANUC S2K series is a high-performance standalone brushless servo or stepper amplifier series that integrates motion controllers and user configurable I/O functionality. The controller can be configured with a rotary transformer or a serial encoder motor feedback model. The encoder based S2K servo model can only be used in conjunction with GE Fanuc S series (SLM, SDM, or SGM) servo motors. The S2K rotary transformer feedback servo controller uses GE Fanuc MTR series (3N, 3S, or 3T) servo motors or third-party motors with appropriate ratings and rotary transformer specifications.

The servo model supports continuous stall torque of 0.84-478 in lb (0.095-54 Nm), while the stepper model supports holding torque of 144-3074 oz in (16.3-21.7 Nm). The servo controller model includes four 230 VAC ratings of 4.3, 7.2, 16, and 28 ampere continuous, as well as two 460 VAC ratings of 7.2 and 20 ampere continuous (the 460 VAC model only provides feedback for the rotary transformer). The peak current of the 230 VAC servo model is twice the continuous rated value, while the 460 VAC servo model is 1.5 times the continuous rated value. The rated value of the stepper controller is 5 amperes.

Support DeviceNet ™ The PROFIBUS communication model includes 14 discrete I/O points. 4.3 and 7.2 ampere servo models and stepper models can also provide 21 I/O points instead of DeviceNet or PROFIBUS communication. All drivers are capable of supporting Modbus/RTU protocol. If the optional Modbus adapter (product number IC800MBUSADP) is used, the standard RS-232 serial port can be used for multi-point applications. This adapter is an externally installed multi-point RS-232 to RS-485 serial port converter.

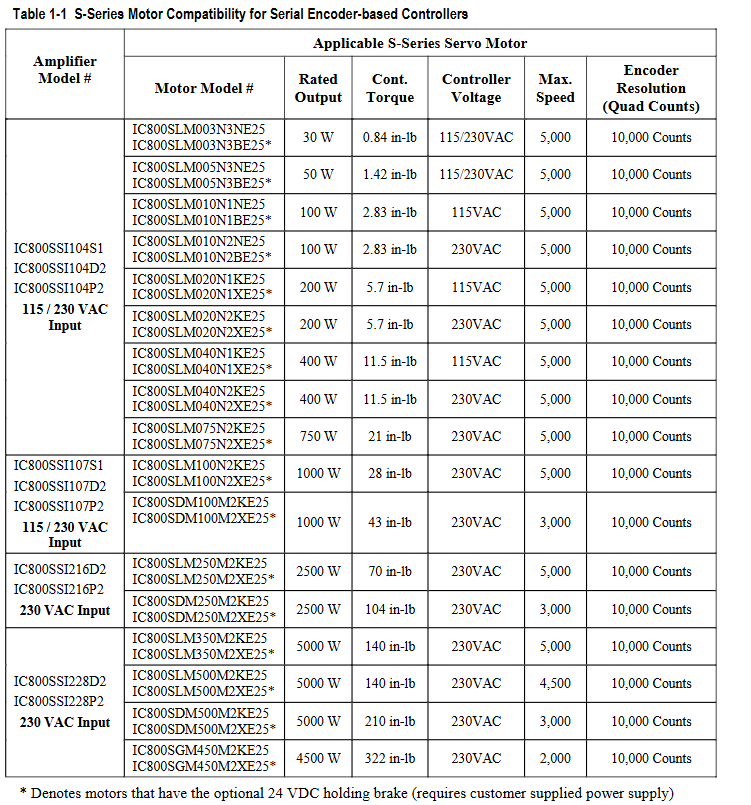

The S2K series controller is optimized for use with GE Fanuc S series or MTR series servo and stepper motors. If the motor and amplifier are not properly matched, overload and possible component damage may occur. Tables 1-1 to 1-3 show the recommended pairing of components.

The S2K series stepper controller requires a single-phase 115 VAC power supply. The S2K series servo controller models rated at 230 VAC and 4.3 or 7.2 amperes can operate on 115 VAC single-phase or 230 VAC three-phase, while all other models are rated for three-phase input. The 230 and 460 VAC models are designed to operate from three-phase power sources, but can be used with single-phase power sources.

The S series servo motors optimized for the S2K series controller range from 30 W to 5 kW and are rated at 230 VAC to achieve full speed. Using a 115 VAC power supply will result in a reduced operating speed of approximately half of the rated speed.

The 30 to 1000 watt S series servo motors (SLM models only), MTR-3S and MTR-3N series, and all stepper motor models are designed with standard NEMA shaft and flange mounting configurations for easy installation onto existing gear reducers and couplings. The 750 watt S series motor is installed with a super large shaft diameter (0.625 inches) for NEMA 34 to handle the peak torque rating of this model. The S series motor models ranging from 1 to 5 kW (except for the SLM100 1kW motor) and all MTR-3T series motors have metric installation configurations.

All servo motors can be equipped with an optional 24 VDC holding brake. These brakes are spring set, electrically released models designed to maintain static loads. The user must provide a separate 24 VDC brake power supply. The 30-750 watt S series motor has a pigtail cable with a box type connector for connecting the motor power supply, encoder, and brake. The 1000 to 5000 watt S series motors have MS style connectors, and the brake power supply (if needed) is integrated with the motor power supply in a common connector/cable. The MTR series servo motors include MS type connectors for brake power input. The MTR-3N and MTR-3T series brake motors integrate the brake power supply and motor power supply into the same cable. The MTR-3S brake motor requires a separate brake power cable (CBL-30-BT).

The S2K series controller is configured and programmed using Motion Developer software on a personal computer. This software is an independent application that works in the Machine Edition software environment, providing tools for beginners to simplify programming and direct code input for advanced users.

Hardware Overview

Specifications

S2K series controllers are used together with S series or MTR series servo and stepper motors. This chapter contains each specification of these components. Table 2-1 shows the available hardware resources on the S2K controller.

Electrical specifications of stepper controller

The S2K stepper controller (IC800STI105xx) is suitable for use on circuits that can provide symmetrical amperes up to 5000 rms and a maximum voltage of 130 volts, when protected by RK5 class 15A fuses. Table 2-2 summarizes the maximum continuous input power requirements for stepper controllers. The actual input power and current are functions of the motor operating point and duty cycle.

Electrical specifications of servo controller

The servo controller model is suitable for use on circuits that can provide symmetrical amperes up to 5000 rms and a maximum voltage of 250 volts, when protected by RK5 fuses. Table 2-3 summarizes the maximum continuous input power requirements. The actual input power and current are functions of the motor operating point and duty cycle.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands