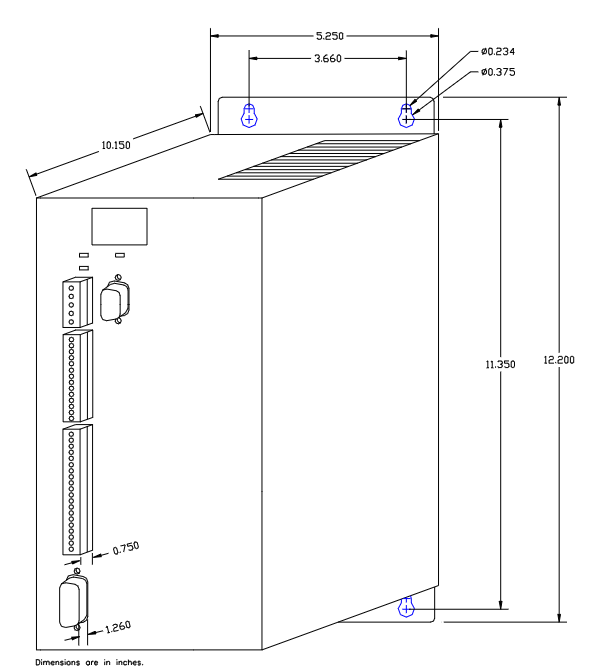

GE FANUC S2K series independent motion controller

Servo motor maintains brake

The servo motor can be equipped with an optional integrated parking brake. The brake is designed for fail safe operation and must be powered by a 24 Vdc power supply to release the brake.

NEMA motor installation

The MTR series and S series motors have installation configurations as shown in the table below. For dimensional information about these motors (including installation dimensions), please refer to the mechanical drawings in Chapter 3.

The MTR series stepper motors have standard NEMA shaft and flange installation configurations, as shown in Table 2-17 below. For the size information of these motors, please refer to the mechanical drawings in Chapter 3.

S series servo motor vibration test

These motors have two types of vibration tests, namely scanning test and resonance point test.

Scanning test: The motor undergoes a 5G variable frequency test on each of the three axes (X, Y, Z) for eight hours. For the purpose of these tests, the X-axis is parallel to the motor axis, the Y-axis is parallel to the encoder connector, and the Z-axis is at a 90 degree angle to X and Y. In this test, the vibration frequency increased from 20 to 3000 Hz within two minutes, and then decreased from 3000 to 20 Hz within two minutes. This pattern was repeated for eight hours.

Resonance point test: Firstly, identify the resonance frequency with the highest vibration when testing the motor in three directions (X, Y, Z) at a variable frequency of 5 G (20 to 3000 Hz). Then, the motor vibrates 10 million times in each direction (X, Y, Z) at the identified resonance frequency.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor