Yokogawa SL1000 high-speed data acquisition unit input module

Key measurement principles and operational points

1. Core technology of strain measurement

Basic formula: Strain value ε=Δ L/L (Δ L is the length change, L is the initial length); The resistance change of strain gauges is proportional to the strain, that is, Δ R/R=K × ε (K is the sensitivity coefficient, usually K=2.0).

Shunt Cal: The 701271 module has a built-in calibration relay that simulates strain by paralleling a known resistor (shunt resistor Rs). The calculation formula is Rs=R × (1-K × ε/2)/(K × ε) (R is the bridge resistance), and it needs to be paired with a bridge that supports shunt calibration (such as 701957/701958). After calibration, the gain error can be controlled within ± 0.5%.

2. Measurement principle of frequency module

Measurement resolution: Based on 625 ps, measurement is achieved by counting the input signal period, such as frequency=1/(counting times x 625 ps), and 16 bit data output (24000 LSB/range).

Filtering and anti-interference: Supports bandwidth limitation from 100 Hz to 100 kHz, with hysteresis function in the range of ± 1% to ± 5%, which can eliminate jitter during contact on/off (adjustable jitter reduction time from 1 to 1000 ms); Low frequency attenuation point ≤ 0.5 Hz during AC coupling, suitable for power frequency (50/60 Hz) signal suppression.

3. Safe operation of high-voltage module

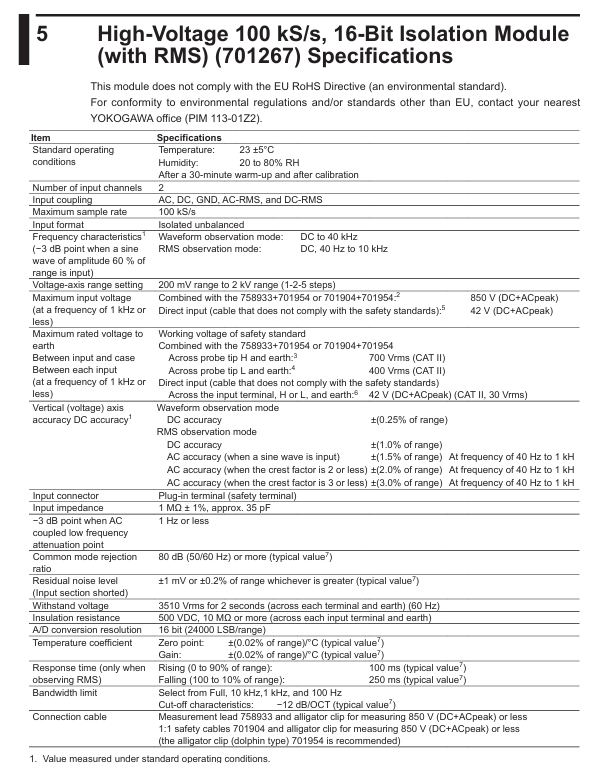

Input restriction: High voltage modules need to be equipped with dedicated probes/cables, such as 701901 (isolated BNC - safety crocodile clip)+701954 (crocodile clip) combination, supporting a maximum of 850 V (DC+ACpeak) input; The limit for direct input is 42 V (DC+ACpeak, CAT II).

Voltage resistance and insulation: High voltage modules generally have a voltage resistance of ≥ 3500 Vrms (2 seconds) and an insulation resistance of ≥ 10 M Ω (500 VDC). During installation, it is necessary to ensure grounding (Class D grounding, ≤ 100 Ω) to avoid safety risks caused by insufficient creepage distance.

Module selection and compatible accessories

1. Key parameters for selection

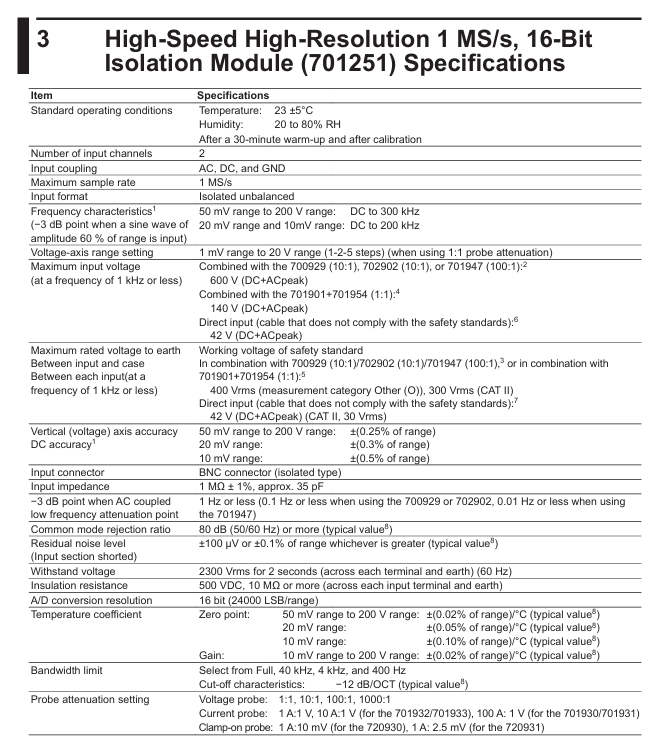

Sampling rate and bandwidth: Select 100 MS/s (720210) for high-frequency signals (such as RF), and 1 MS/s for low-frequency high-precision signals (such as sensors) using a 16 bit module (701251);

Isolation requirements: Isolation modules (such as 701250/720268) are preferred for industrial strong interference environments, while non isolation modules (such as 701255) are optional for laboratory low interference environments;

Measurement types: strain testing select 701270/701271, high voltage monitoring select 701267/720268, temperature voltage mixed measurement select 701261/701265.

2. Recommended compatible accessories

Example of accessory type and model, applicable module functions

Voltage probe 700929 (10:1, 20-45 pF) for high-speed/high-voltage module safety measurement of 600 V (DC+ACpeak) signal

Current probe 701930 (150 A, 100 A: 1 V) full series voltage module non-invasive current measurement, SL1000 can be powered

Strain bridge 701957 (D-Sub, 120 Ω) 701271 with shunt calibration, 5-meter shielded cable

Connect cable 701901 (isolated BNC crocodile clip) to the high-voltage module for isolated high-voltage signal connection, paired with 701954 crocodile clip

Safety and maintenance precautions

1. Core security standards

Voltage limit: Strictly adhere to the maximum input voltage of the module, such as the maximum 1000 V (DC+ACpeak) when the 720210 module is paired with a 10:1 probe, and only 42 V when directly input. Overvoltage may damage the module or cause safety accidents;

Static protection: The module contains static sensitive components, and an anti-static wristband should be worn during operation. Maintenance should be carried out at a grounding workstation;

Explosion proof and compliance: Some modules (such as 701250/701267) do not meet the EU RoHS directive, and alternative models need to be confirmed for export to the EU; The use in hazardous areas should refer to the explosion-proof level requirements in the Module Safety Precautions Manual (IM 701250-04E).

2. Key points of daily maintenance

Calibration cycle: It is recommended to calibrate once a year, and high-precision modules (such as 701265) should be calibrated every 6 months to ensure measurement accuracy;

Cleaning and storage: Wipe the surface of the module with a soft cloth and prohibit the use of organic solvents; Long term storage environment temperature -30~70 ℃, humidity 20~80% RH (non condensing);

Troubleshooting: If there are measurement abnormalities, priority should be given to checking the wiring (such as shielding layer grounding) and probe compatibility (such as attenuation ratio setting). The high-frequency module needs to confirm whether the bandwidth limit matches the signal frequency.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands