YOKOGAWA CENTUM VP Integrated Production Control System (TI33J01A10-01EN)

YOKOGAWA CENTUM VP Integrated Production Control System (TI33J01A10-01EN)

System positioning and development background

1. Core positioning

CENTUM VP is the 8th generation distributed control system (DCS) of Yokogawa, designed based on "high availability, flexible scalability, and full lifecycle cost optimization". It can achieve integrated management of factories from "control safety asset production", support monitoring scale of up to 1 million tags, and adapt to the needs of complex factories from small to super large.

2. Development process

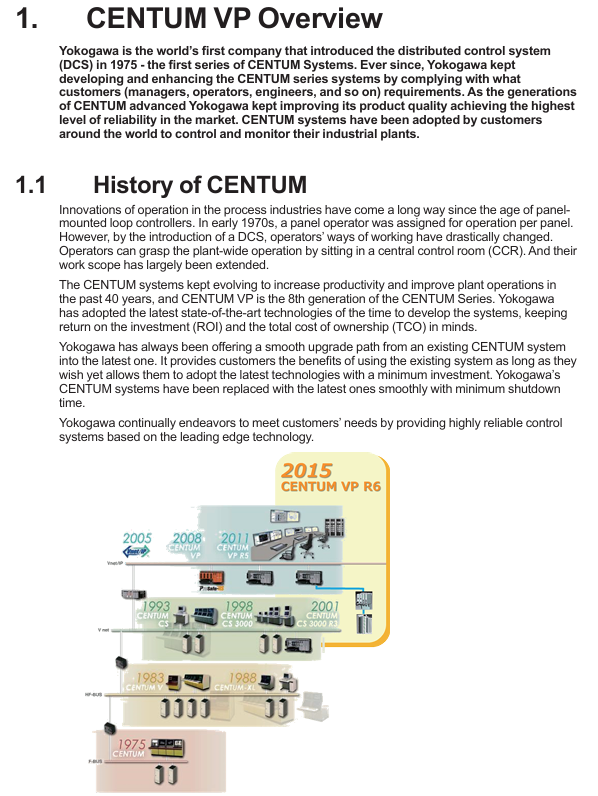

In 1975, Yokogawa launched the first CENTUM series DCS, pioneering distributed control;

Iterative upgrade: After 7 generations of products including CENTUM-XL, CENTUM V, CENTUM CS, etc., it gradually evolved to CENTUM VP after 2005, released R6 version in 2015, and updated to the 6th edition manual in 2019;

Market size: As of March 2019, over 28900 projects have been delivered globally, with core applications in fields such as oil and gas (with the highest proportion), petrochemicals, and chemicals. Europe, the Middle East, and Asia are the main markets.

Core advantages of the system

CENTUM VP focuses on the six core advantages of "operation, engineering, control, production management, maintenance, and project" scenarios, as follows:

Core advantages of the scene

On the operational level, there is a unified user interface that integrates control, security, and asset data to avoid information overload;

2. Continuous optimization: Support the solidification of best practices and scenario based operation suggestions.

Engineering level 1. Flexible design: Based on the AD Suite engineering environment, it supports "modular engineering" (independent of hardware configuration design control logic) and "non modular engineering" (hardware design before design);

2. Efficient reuse: Modules can reuse historical project experience to shorten project cycles.

Control layer 1. Ultra high reliability: FCS (Field Control Station) availability reaches 99.99999%, supporting fault avoidance, fault-tolerant operation, and rapid recovery;

2. Flexible I/O: Supports N-IO modules (software configured with DI/DO/AI/AO signals) to reduce wiring costs.

Production management 1. Fast PDCA cycle: Integrate MES with enterprise systems through S95/B2MML standards;

2. Security integration: Built in control network security authentication to ensure data transmission security.

Maintenance level 1. Online upgrade: supports non-stop modification and upgrade, with no single point of failure risk;

2. Long term compatibility: Maintain backward compatibility during 40 years of product iteration to protect historical investments.

Project Level 1: Rapid Delivery: Integrating DCS, SIS (Safety Instrumented System), PIMS (Factory Information Management System), etc. to reduce integration risks;

2. Cost controllable: Label authorization is only available in three levels: 8000 points (small), 100000 points (medium to large), and 1 million points (multi factory linkage).

System architecture and core components

CENTUM VP adopts a "3+N" infrastructure (3 core components+N extension components), which is interconnected through Vnet/IP control network and supports flexible expansion.

1. Three core components

(1) Human Interface Station (HIS)

Positioning: Operator monitoring and operation terminal, based on Intel x86 PC+Windows system, installed with operation monitoring software;

Features: 1 No single point of failure: Multiple HIS can backup each other without relying on servers;

2. Flexible display: Supports 16:10/4:3 widescreen display, multi monitor linkage, and windows can be moved across screens;

3. Compliant with standards: Following EEMUA # 191 Alarm System Design Guidelines, integrated with Alarm Management Software (CAMS).

(2) On site Control Station (FCS)

Positioning: System core controller, independently designed and manufactured by Yokogawa, responsible for control calculation and I/O signal processing;

Hardware structure: divided into cabinet type and rack type, including FCU (field control unit)+node unit (installation of I/O modules), supporting multi node unit expansion of I/O points;

Reliability design: 1 Dual redundancy: processors, power supplies, I/O modules, and networks are all redundant;

2. Fault handling: seamlessly switch to the backup module in case of a fault, and support online replacement of the faulty module;

3. Independent operation: Basic control can be achieved without the need for HIS, and data and logic are stored locally.

(3) Control network (Vnet/IP)

Technical specifications: Compliant with IEEE802.3 Ethernet standard, 1Gbps bandwidth, dual redundancy;

Core features: 1 Deterministic communication: Yokogawa proprietary protocol ensures real-time performance, HIS data update interval ≤ 1 second;

2. Precise synchronization: supports time synchronization within 5ms for each site;

3. Open interconnection: Non CENTUM components (such as third-party PLCs and instruments) can be connected.

2. Extension components (configured as needed)

Component Name Function Positioning

Install AD Suite engineering software on the Engineering Station (ENG), responsible for system configuration, control logic design, and parameter debugging; Support "modular" and "module free" projects.

The General Subsystem Gateway (GSGW) integrates subsystem data through OPC DA interface to achieve unified monitoring between subsystems and CENTUM VP.

The System Integrated OPC Station (SIOS) integrates third-party Process Control Systems (PCS) based on OPC interfaces to achieve bidirectional interaction between data and alarms.

The Unified Gateway Station (UGS/UGS2) integrates STARDOM controller and third-party PLC, supports OPC DA/A&E, Modbus, Ethernet/IP and other protocols, and can be dual machine redundant.

Advanced Process Control Stations (APCS) execute advanced control algorithms (such as Model Predictive Control) to improve factory operational efficiency.

Bus Converter (BCV) realizes communication relay between CENTUM VP and previous generation systems (such as CENTUM CS 3000, μ XL).

ProSafe RS T Ü V SIL3 certified safety instrumented system, responsible for emergency shutdown (ESD), fire and gas detection (F&G), burner management (BMS), seamlessly integrated with CENTUM VP.

Engineering Environment (AD Suite)

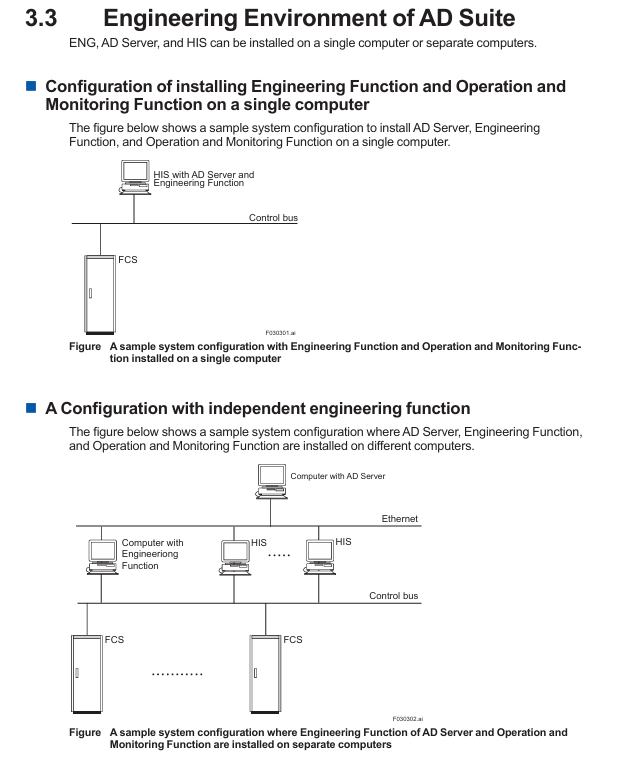

AD Suite is the core engineering environment of CENTUM VP, replacing traditional engineering tools of previous generation systems and supporting "centralized data management+flexible engineering methods". It consists of three major modules:

1. Core components

AD Server (Automated Design Server): 1 Centralized storage of engineering data (ADMDB database);

2. Manage project change history, support backup and recovery;

AD Organizer: 1 Modular engineering core tool, supporting module creation, instantiation, and batch editing;

2. View change history and dependency analysis results;

VP Builder: 1. Non modular engineering tools, including System View, Recipe View, etc;

2. Responsible for the engineering configuration of non FCS sites such as HIS and UGS.

2. Engineering methods

AD Suite supports two engineering methods to meet different project requirements:

Engineering method applicable scenarios, core processes

Scenario 1: Create a "class module" (template, including control logic, alarm properties, and design documents) for large-scale projects in modular engineering that require the reuse of historical experience;

2. Instantiate the "application module" (actual control unit);

3. Batch editing and binding hardware (I/O configuration can be modified later).

Scenario 1 for small projects without modular engineering and fixed hardware configuration: Firstly, determine the hardware configuration of FCS, I/O modules, etc;

2. Based on hardware design, control logic and I/O signal allocation;

3. Download directly to the website and run it.

3. Key functions (including standard and optional)

Standard features: No module engineering, change history management, AD Server/project management;

Optional features: 1 Modular engineering package: supports module creation and reuse;

2. Parameter tuning management: Compare design values with on-site values and issue parameters in batches;

3. Batch editing: tabular editing of control logic and alarm attributes, supporting consistency checks;

4. Change control: Manage the change process through ModPack forms (application analysis execution testing confirmation);

5. Dependency analysis: Analyze control logic I/O、 Assess the correlation between graphic labels and evaluate the scope of impact of changes.

Control Function (FCS)

FCS is the control core of CENTUM VP, responsible for the entire process of "data acquisition control calculation signal output", with the following core characteristics:

1. Hardware design

Compact layout: reduces equipment footprint, supports installation in IEC Zone2/Class I Div.2 hazardous areas, and lowers installation costs;

Redundant design: The processor, power supply, I/O module, and I/O network are all doubly redundant, with Active/Standby modules running synchronously and seamlessly switching in case of failure;

Flexible expansion: By expanding the number of I/O points through node units, it supports the mixed use of FIO (traditional I/O) and N-IO (software configured I/O) modules.

2. Software functions

Function Block Library: Provides monitoring, control (PID, etc.), calculation, logic, sequence control and other functional blocks, supporting conventional control, advanced control, batch control, etc;

Unit monitoring: defining multiple devices as "units" for unified operation and monitoring, adapting to batch processes and complex continuous processes;

Online maintenance: Support engineering stations to modify control logic and parameters without stopping the machine, and directly download them to FCS after modification without affecting on-site control.

3. Communication support

Supports multiple digital fieldbuses and third-party protocols to adapt to different smart devices:

Fieldbus: Foundation Fieldbus, HART, PROFIBUS-DP, PROFINET, DeviceNet, ISA100.11a wireless;

Universal protocols: Modbus RTU, Modbus TCP/IP, Ethernet/IP, IEC 61850 (for IED devices).

Security and integration capabilities

1. Integration with ProSafe RS (SIS)

Safety positioning: T Ü V SIL3 certification, used for ESD (emergency stop), F&G (fire and gas detection), BMS (burner management);

Integration advantages: 1 Unified operating environment: HIS can directly monitor ProSafe RS alarms and status without switching interfaces;

2. High availability: Adopting the "Pair&Spare" architecture, low false trip rate, ensuring factory safety and continuous operation;

3. Safety compliance: Complies with IEC 61508 standard and supports safety lifecycle management.

2. Openness and interoperability

Global HIST Network: Set up testing sites in Japan, the Netherlands, the United States, and Singapore to verify the interoperability between CENTUM and third-party devices, and make the test results public

OPC Integration: Implementing data exchange with third-party systems through ExaOPC (OPC Server), supporting OPC DA (Data Access) and OPC A&E (Alarm and Event);

Multi system interconnection: 1 Connect the previous generation CENTUM system through BCV;

2. Implement wide area network (including satellite communication) interconnection across Vnet/IP domains through WAC Router;

3. Integrate STARDOM controller and third-party PLC through UGS/UGS2.

Factory full lifecycle support

CENTUM VP optimizes costs throughout the entire lifecycle of "design build operation upgrade", with the following core measures:

1. Design phase

Accurate cost estimation: early calculation of FCS load and clarification of hardware requirements; Label authorization is divided into three levels to reduce engineering change costs;

Virtual testing: supports virtual FCS/HIS environment, can test control logic and operation functions without hardware, shorten debugging cycle, and can be used for operator training system (OTS).

2. Operation and maintenance phase

Online upgrade: PC based sites (HIS/ENG) can be upgraded with just one click, while FCS can be upgraded as needed (without using new features);

Asset management: Integrate PRM (Plant Resource Manager) software to manage on-site equipment (such as HART and FF devices) and optimize maintenance plans.

3. Upgrade/Migration Phase

Smooth Migration: Supports migration from previous generation systems such as CENTUM CS 3000/CS 1000, while retaining on-site cables, I/O modules, and control networks;

RIO system upgrade: The RIO (Remote I/O) system of CENTUM CS/VP can be upgraded to the latest A2FV70 series FCS, reusing existing field wiring and reducing downtime.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com