Yokogawa SC200 Intelligent Two Wire Conductivity Transmitter System (IM12D08B01-01E)

Yokogawa SC200 Intelligent Two Wire Conductivity Transmitter System (IM12D08B01-01E)

System positioning and core composition

1. System positioning

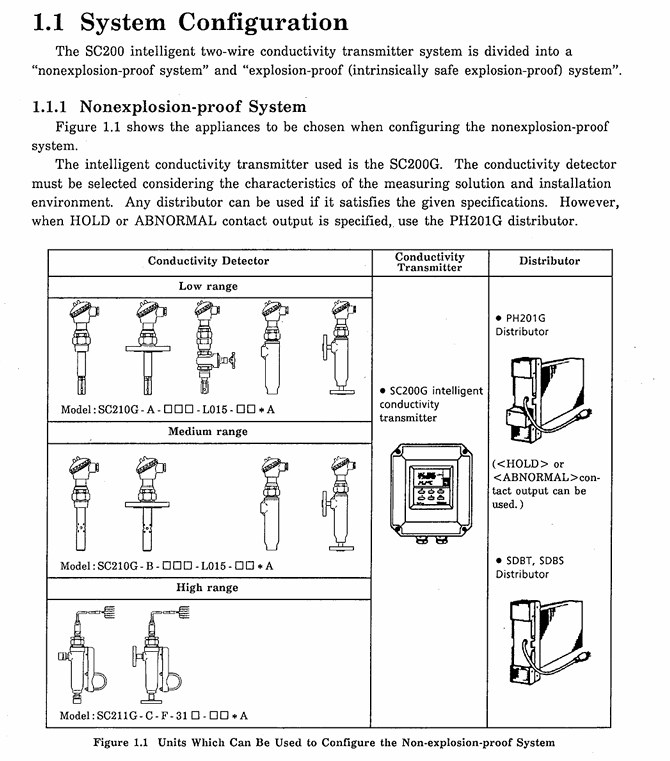

The SC200 system is an intelligent conductivity measurement solution based on microprocessors, which achieves continuous online measurement of solution conductivity through a combination of "transmitter+detector+distributor". It can convert the measured value into conductivity at a reference temperature based on temperature compensation, and support fault diagnosis and signal output control, meeting the measurement needs of ordinary industrial environments and hazardous environments (including explosive gases).

2. Core components

The system consists of three core components, each with clear functions and classifications:

Component type, specific model/classification, core functions

Conductivity detector - SC210G (2-electrode type):

-SC210G-A (low range, electrode constant 0.05 cm ⁻¹)

-SC210G-B (medium range, electrode constant 5 cm ⁻¹)

-SC211G-C (4-electrode type, high range, electrode constant 10 cm ⁻¹) contact measurement solution conductivity, built-in temperature sensor (thermistor for SC210G, Pt1000 for SC211G) for temperature compensation; Supports direct insertion (screw/flange) and flow-through (pipe/flange) installation.

Intelligent Conductivity Transmitter - SC200G (Non Explosion proof Type)

-SC200S (intrinsic safety explosion-proof type) receives the conductivity and temperature signals of the detector, and outputs 4-20 mA DC analog signals after processing; Support digital display, parameter setting, and self diagnosis; Explosion proof type needs to be used in conjunction with safety barriers.

Distributor/Safety Barrier - Distributor: PH201G (supporting HOLD/fault contact output), SDBT/SDBS (universal type)

-Safety Barrier: BARD400 (for intrinsically safe explosion-proof systems) provides power to the transmitter, receives 4-20 mA signals, converts them to 1-5 V DC, and outputs them to the recorder; Safety barriers are used to limit the energy of circuits in hazardous environments and prevent explosions.

Detailed explanation of technical specifications

1. Specification of conductivity detector

(1) Basic parameters

Model measurement range electrode constant contact material (sensor) measurement temperature range measurement pressure range protection level

SC210G-A 0~200 μ S/cm 0.05 cm ⁻¹ SUS316, polytetrafluoroethylene resin, fluororubber 0~105 ℃ (PP bracket 100 ℃) 10 kgf/cm ² (PP bracket 5 kgf/cm ²) IP65 (NEMA 4)

SC210G-B 200 μ S/cm~20 mS/cm 5 cm ⁻¹ Platinum, glass SUS316、 Fluororubber with SC210G-A and SC210G-A IP65 (NEMA 4)

SC211G-C 1 mS/cm~1 S/cm 10 cm ⁻¹ Platinum, glass, polyvinylidene fluoride resin, fluororubber 0~80 ℃ 2 kgf/cm ² Rain proof (JIS C0920)

(2) Installation and Interface

Direct insertion type: supports Rc 1-1/2 (PT thread), 1-1/2 NPT thread, or JIS 10K-50-RF, ANSI CLASS 150-2-RF flange;

Flow type: The bracket material is divided into SCS14 (stainless steel) and PP (polypropylene), and the interface is Rc 1/2, 1/2 NPT thread, or JIS 10K-15-RF/FF, ANSI CLASS 150-1/2-RF/FF flange.

2. Smart transmitter specifications

(1) Basic parameters

Parameter category specification details

Measurement and output conductivity display range 0~1999 mS/cm, output signal 4~20 mA DC (linear/line approximation/reverse output), maximum cable length 2000m (non explosion proof)/700m (explosion proof);

The temperature compensation reference temperature is adjustable from 0 to 100 ℃, and the compensation coefficient is adjustable from -10% to+10%/℃. It supports NaCl solution characteristic compensation or custom solution characteristic compensation;

Environmental adaptability: working temperature -10~+55 ℃, storage temperature -30~+70 ℃, humidity 10~100% RH (non condensing); The shell material is cast aluminum (polyurethane baked paint) with a protection level of IP65;

Accuracy and repeatability of conductivity measurement accuracy ± 1% range (1 μ S/cm~2 S/cm), ± 0.02 μ S/cm (0~1 μ S/cm), repeatability ± 0.5% range;

The self diagnostic function supports diagnosis of temperature exceeding limits, conductivity exceeding limits, electrode contamination, temperature coefficient errors, circuit faults, etc. When a fault occurs, it outputs 22.0 mA (when the burnout function is turned on);

(2) Explosion proof specification (SC200S)

Explosion proof type: Intrinsic safety type (Ex ia IIC), to be used in conjunction with BARD400 safety barriers;

Environmental restrictions: Installation height ≤ 1000m, humidity 45~85% RH, prohibited from installation in Zone 0 hazardous environment;

Circuit parameters: Cable inductance ≤ 2.2 mH, capacitance ≤ 35 nF, ensuring no contact between intrinsic safety circuits and non intrinsic safety circuits.

Installation and wiring process

1. Installation of conductivity detector

(1) Preparation before installation

Site selection requirements: easy to maintain, measuring solution temperature/pressure in accordance with specifications, no bubbles, stable liquid level;

Interface preparation: Direct insertion type requires processing of threaded/flange holes that meet specifications (electrode insertion depth ≥ 60mm); The flow type (PP bracket) requires the installation of a nominal 50A (outer diameter 60.5mm) mounting pipe, which can be installed vertically or horizontally.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands