Paper industry development goals

(1) Adjusting the structure of raw materials

The contradiction between the supply and demand of raw materials is prominent, and the external dependence of wood chips, pulp and paper will increase year by year. While making full use of foreign pulp and forest resources and realizing the complementary advantages of forest paper industry chain, it is necessary to focus on the adjustment of raw material structure. The construction of forest-paper integration project will become a continuous lasting work, is the future development direction of the industry, and is an important measure to promote the sustainable development of the paper industry. Continue to improve the policy of "promoting paper with forest, raising forest with paper, combining forest and paper with common development", promote the integration of forest and paper, increase the area of domestic papermaking raw material forest, and improve the domestic wood fiber raw material supply capacity.

Make up for the shortcomings of the industrial chain and supply chain, continue to make full use of limited resources, and increase the utilization of wastes such as forestry "three leftovers", sugar industry waste bagasse, agricultural straw, wetland reed and recycled paper. Reduce the risk of high dependence on paper fiber raw materials and ensure industrial safety.

1. Moderate layout of chemical and semi-chemical pulp, forest and paper integration enterprises in the southeast coast to supplement the resource loss in the recycling of waste paper;

2. Accelerate the construction of self-owned forest land, improve the self-sufficiency rate of resources, and accumulate carbon sinks and biomass resources;

3. Multi-channel recycling of domestic waste paper and overseas recycling of paper packaging pulp to maintain domestic raw material supply;

4. Develop bamboo pulp and encourage the construction of interforest road infrastructure, and scientifically utilize bagasse, straw and other non-wood raw materials;

5. Carry out international cooperation to develop and build overseas industrial forest bases.

2. Improving the corporate structure

Seek a more reasonable industrial layout across the country, focusing on the communication, exchange and cooperation extension of upstream and downstream industries. We will optimize the distribution of regional industrial chains, encourage mergers and reorganizations of enterprises, prevent low-level duplication of construction, improve the level of enterprise operation and management, implement a modern enterprise system, and become larger and stronger into a number of large enterprise groups.

1. Large, small and medium-sized specialized division of labor: guide the specialization and scale of mass product production, guide small and medium-sized paper enterprises to develop in a specialized, fine, special and new direction, implement horizontal joint, and improve the level of specialization and anti-risk ability.

2. Improve the concentration of production capacity: Guide the development of large-scale pulp and paper enterprises through mergers and reorganizations and joint ventures to form a comprehensive pulp and paper enterprise group with international competitiveness. Cultivate leading enterprises of paper products, improve the concentration of paper products enterprises, and improve the scale efficiency of enterprises.

3. Actively eliminate backward production capacity: shut down production facilities that cannot meet the emission standards, have relatively backward energy consumption levels, and have weak product competitiveness, and ensure that backward production capacity or production facilities that have been closed will not resume production. Continuous technological transformation, continuous optimization and improvement of production capacity, and maintain the technical level and competitiveness of production capacity at the international advanced level.

3. Conserving energy and reducing emissions

1. Energy-saving targets

During the "14th Five-Year Plan" period, the paper industry should increase investment in energy-saving transformation, give full play to the role of cogeneration, make full use of energy such as residual pressure and waste heat generated by the production link, increase the recycling and utilization of organic waste liquid, organic waste and biomass gas, and nearly zero emission of solid waste to maximize resource utilization.

Strive to "14th Five-Year" period of the industry unit product actual process comprehensive energy consumption (purchased and self-produced energy total) pulp from 350kgce/t to 320kgce/t, paper and cardboard from 480kgce/t to 450 kgce/t, to reach the international advanced level.

In view of China's per capita paper consumption will continue to increase before the national economy reaches the medium developed countries, as well as the impact of carbon peak and the implementation of the ban on waste paper import policy, the total energy consumption of the paper industry will continue to rise before 2030. After 2030, we will strive for technological breakthroughs in energy use in the industry, make theoretical and technical reserves for the significant replacement of fossil energy by alternative energy sources, and avoid a significant jump in the overall energy consumption of the whole industry caused by the failure to play a role in cogeneration due to the reduction of fossil energy. Strive to increase afforestation, increase the proportion of biomass energy, energy-saving technology transformation, improve the efficiency of cogeneration, eliminate relatively backward production capacity and moderate control of new production capacity and increase the import of finished paper and other measures to ensure that carbon emissions gradually reduce after reaching the peak.

2. Pollutant reduction

We will consolidate our achievements in emission reduction, maintain a low level of pollutant discharge, and increase the comprehensive utilization of solid waste and the energy utilization of biomass from solid, liquid and gaseous waste. Strengthen the collection and treatment of unorganized dispersed pollutants, and improve the automation and operation management level of environmental protection facilities. Licensed discharge, apply for discharge permits according to law and regulations, and do a good job of self-monitoring. Discharge in good faith according to law, submit implementation reports on time and disclose information in a timely manner. Maintain the amount of pollution per unit product at the international advanced level.

(4) Improve the quality of varieties

Adhere to the goal of meeting the people's growing needs for a better life, and adapt to the needs of personalized, differentiated and quality products in downstream industries and society.

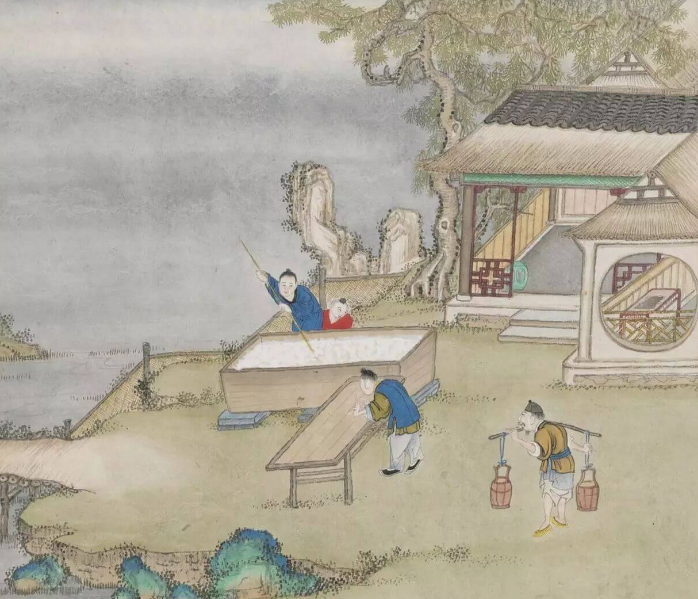

Through the innovation and technological transformation of process technology and equipment, improve the level of pulp and paper production equipment, processing design level, and craft art level, promote industrial upgrading with lean production, and enhance the status and image of the industry.

Take the initiative to lead the diversified consumer market demand, and form a high, fine, special, differentiated, personalized product structure. According to the actual technical needs of users, increase the variety of paper and paper products, improve product quality, cultivate more paper brands, enhance brand influence and competitiveness, and transform product services to directional customization and one-to-one service. Subdivide varieties, increase the supply and variety of domestic industrial and agricultural technical paper, scientific and technological defense paper and pulp.

(5) Define the objectives of the stage

In accordance with the 14th Five-Year Plan for National Economic and Social Development and the Long-range Goals for 2035, and the goal of "reaching the level of moderately developed countries in terms of per capita GDP" by 2035 and doubling the economic aggregate or per capita income by 2035, Through the paper industry attributes, status, role and economic development and the relationship between the world's medium and above developed countries paper consumption capacity analysis, China's paper consumption trend based on economic growth positive, normal and negative three scenarios to simulate, is expected to 2035 domestic paper and cardboard demand or will reach 190 million tons, 170 million tons and 140 million tons. If the national carbon peak target in 2030 is taken into account, the growth of paper and cardboard production capacity may be forced to restrain, so the domestic production of paper and cardboard should be controlled within 170 million tons in 2035, with an average annual growth of about 2.5%.

Development goals for 2025

1. The total output of paper and paperboard in China reached 140 million tons (annual per capita consumption reached 100 kg);

2. Raw pulp production of 30 million tons;

3. 90 million tons of paper products;

4. Unit product pulp consumption, energy consumption, water consumption, pollutant discharge to maintain the international advanced level;

5. Product structure continues to adjust, product quality continues to improve, varieties continue to enrich.

Development goals for 2035

1. The total output of paper and paperboard reached 170 million tons (annual per capita consumption reached more than 120 kg);

2. The proportion of raw pulp is more than 30%;

3. Paper products output 120 million tons;

4. Strive to use biomass energy to account for more than 35% of energy consumption;

5. Cogeneration ratio of more than 90%;

6. Unit product pulp consumption, water consumption, energy consumption, pollutant discharge reached the international leading level.

Second, consolidate the industry foundation

(1) Focus on talent strategy

Talent is the basis for high-quality development of the industry, give full play to the role of talent as the first resource, and implement the policy of respecting labor, respecting knowledge, respecting talents, respecting intellectual property rights, and respecting creation.

Strengthen scientific and technological innovation, management innovation, and cultivate new competitive advantages in the paper industry with innovation. Pay attention to the bottleneck of talents in the development, and train the skilled professional industrial workers. Efforts to absorb high-quality, multidisciplinary, international shortage of talents, the introduction of cross-industry and cross-field international high-end scientific and technological talents, management talents, marketing talents, etc.

In the actual work of training talents, the introduction and use of good talents, all-round training, create a good quality, complete categories, the structure of the basic reasonable talent team, cultivate the reserve army of young scientific and technological talents, to meet the needs of modern pulp and paper enterprises for high-level talents.

2. Pursuing scientific and technological progress

Scientific and technological progress is the basis for high-quality development. We will improve our capacity for technological innovation, increase investment in research and development of theories and processes, form a scientific and technological innovation body with enterprises as the main body and combining production, university, research and application, and promote the agglomeration of various innovation factors to enterprises.

Strengthen the independent innovation capacity building of paper equipment manufacturing enterprises. Increase the research and development of a new generation of pulp, paper and paper products technology and equipment, improve the level of autonomy of technical equipment, and strive to close the technical level and equipment manufacturing capacity of key backbone papermaking equipment manufacturing enterprises to the international advanced level.

Use the characteristics of pulp and paper to carry out multi-directional product research, and develop technologies and products with independent intellectual property rights. Efforts are made to carry out theoretical and technical research on carbon neutrality, seek breakthroughs in key technologies, and promote the sustainable and stable development of the paper industry.

3. Practicing social responsibility

Raise awareness of social responsibility in all aspects and take the initiative to assume social responsibilities. Protect the rights and interests of employees, promote traditional papermaking culture, actively participate in social public welfare undertakings for the benefit of society, promote the development of education and social undertakings, and improve the social image of the industry.

The consciousness of energy conservation and environmental protection in the paper industry has changed from forced to conscious, from passive to active, from asking me to do to I want to do. To publicize the natural green properties of paper to the public, consciously maintain the good social image of green and low-carbon paper industry, and create new space for development. Continue to follow the concept of "clear water and green mountains are golden hills and silver mountains", so that the whole cycle of papermaking is fully integrated into a more scientific and reasonable social circular economy system.

4. Maintaining fair competition

Strengthening industry self-discipline is an important condition for the high-quality development of the industry. Jointly maintain and implement the self-discipline convention of the industry, maintain the integrity of the industry, maintain the fairness of the industry market, and constantly improve the market environment for fair competition in the industry. Prevent unfair competition in the industry and damage to the development of the industry, the interests of the industry.

Improve the industry production capacity and market notification and early warning mechanism, make full use of the futures market platform, timely collate and release industry production and sales situation, production capacity construction, industry development dynamics and product volume and price index information. In combination with the early warning mechanism of some varieties established by the industry, timely inform the development of the industry, provide timely tips for the conversion or structural adjustment of varieties with excess or market shrinkage, and avoid the blind and disorderly development of the industry and vicious competition.

3. Achieve high-quality development

The contradiction between the people's growing needs for a better life and the unbalanced and inadequate development has become increasingly prominent, pointing out the direction for the sustainable development of the paper industry and providing a broad space for future development. The paper industry to achieve high-quality development, from the paper power to the paper power will be reflected in the following aspects:

(A) Production-oriented to service-oriented leap

To strengthen the service as the focus, improve the enterprise's consulting and service capabilities to users. Integrate upstream and downstream industries and technologies, expand the industrial chain, build a professional user service team, target production and services for users, and upgrade from a simple manufacturer to a production, technology and service provider.

Actively design and develop products according to customer needs, and carry out research and development of pulp and paper multi-directional applications. Segmented development of products for users and uses to meet the needs of high quality, multi-faceted, diversified, personalized and multi-level.

Focus on innovation and development, strengthen the leading position of enterprises in technological innovation, and make all-round innovation in the market, product quality and variety, technical equipment, business philosophy, and service level.

We will give full play to the advantages of industrial scale, supporting advantages and first-mover advantages in some fields, promote high-end, intelligent and green traditional industries, and develop service-oriented manufacturing.

Promote Internet applications, and vigorously promote Internet + design, production, sales and logistics in the paper products industry. Innovate the production design and marketing model of end products such as paper packaging, brochures, reproduction printing products, and household paper, and provide the society with more and more flexible product choices and more convenient and fast services.

2. Meeting the needs of society and people's livelihood

When China's per capita GDP reaches the level of medium developed countries, the per capita paper consumption will also reach the level of medium developed countries. In order to further meet the needs of society and people's livelihood, through supply-side structural reform, we will continuously develop richer varieties and more specialized products, expand application fields, improve product technology content, reduce excess functions, cultivate new consumption, and inherit national culture.

Through the application of interdisciplinary technology in products, to meet the technical needs of downstream industries. Improve and optimize the quality of printed writing paper, tissue paper, packaging paper and paperboard, special paper and paperboard, paper products and other products to meet the needs of diversified and personalized consumer markets.

(3) All-round sustainable development

To achieve the goals set forth in the 14th Five-Year Plan for National Economic and Social Development and the Outline of the 2035 Vision Goals, as well as the specific requirements of "accelerating the transformation and upgrading of enterprises in key industries such as chemical and paper making and improving the green manufacturing system", and comprehensively improving the efficiency of resource utilization, After the peak of carbon emissions in 2030, carbon emissions will stabilize and decrease, and build a healthy and low-carbon industrial value chain.

Make good use of both domestic and foreign resources. Through the use of foreign high-quality fiber resources to improve the quality of domestic recycled waste paper pulping, promote the construction of domestic forest-paper integration projects and scientific use of non-wood raw materials, gradually increase the supply of domestic fiber raw materials, and ensure social supply and sustainable development of the industry.

We will transform the mode of development and, in accordance with the principles of reduction, reuse and resource recovery, improve the efficiency of the use of water resources, energy, land and plant raw materials, and reduce energy consumption and pollutant discharge. Improve the level of technology and equipment; Actively promote the paper industry can be recycled, renewable, sustainable development of the good image; Create green factories and guide green consumption; We will rely on innovation to drive upgrading, improve quality and increase efficiency, and foster new growth areas and new competitive advantages.

To achieve green paper industry, resource-saving and environment-friendly industry as the construction goal, adhere to the development of low-carbon green products. Facing and making full use of the challenges and opportunities of the new era, the paper industry will develop into a complete circular economic development system with recyclable resources, low energy consumption, low emissions, and the natural carbon cycle.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands