Allen Bradley 1391-DES series digital AC servo drive

The parameters are divided into three levels: View level (only viewing the operating status, such as speed and current), Modify level (configuring system parameters, such as speed limit and current loop gain), and Maintenance level (advanced parameters, such as inertia compensation and friction compensation), which need to be unlocked through specific key combinations (such as simultaneously pressing the up/down/left arrow+Enter key for Maintenance level).

Core parameters: simulated speed gain (parameter 211, default 500rpm/V, can be calculated based on "maximum motor speed/maximum command voltage"), speed limit (parameters 144/145, default 10% higher than motor rated speed), current limit (parameters 156/157, default 300% motor rated current).

Start debugging process

Preliminary inspection: After confirming that the wiring is correct, power on to verify that the control voltage (± 12V DC,+5V DC) and bus voltage (300V DC) are normal and there are no fault alarms.

Guided start: When powered on for the first time, the driver automatically guides the motor model selection, rotation test (verify motor wiring, rotate clockwise/counterclockwise for 5 seconds each), and zero speed offset calibration (automatically eliminate command offset).

Auto Tune: Starting with parameter 190, the driver automatically measures the system inertia and friction coefficient, calculates the optimal speed loop gain (Kp/Ki), and is suitable for most scenarios; Manual tuning requires adjusting parameters 168 (proportional gain) and 169 (integral gain) to control the speed response overshoot within 20% -30%.

Troubleshooting and Maintenance

fault diagnosis

Fault indication: Front LED light (STATUS light flashing red=fault, green constant light=normal; ENABLE light on=driver enabled), LCD displays specific fault codes (such as "amp overttemp"=driver overheating, "resolver loss"=rotary transformer fault).

Common troubleshooting:

Overvoltage fault: Check whether the input voltage and shunt resistor are open circuited/selected incorrectly, and whether the load inertia is too large;

Rotating transformer fault: Check if the resolver wiring is loose/reversed, and if the cable length exceeds 600 feet;

Overcurrent fault: Check if the motor is short circuited, if the current limit parameter is set too low, and if the load is stuck.

Maintenance points

Regular inspection: clean the cooling fan, confirm that the wiring terminals are not loose, and that the braking resistor has no signs of overheating;

Component replacement: The fuse should be replaced according to the manual model (such as Bussmann KLM10 10A/500V for DES15), avoiding using alternative models; When replacing the control board, pay attention to ESD protection (wear an anti-static wristband).

Supporting equipment and accessories

Adaptation components

Motor: 1326AB series AC servo motor (including Torque Plus series), which needs to be matched with driver current (such as DES22 compatible with 1326AB-B3E motor);

Transformer: 1391 isolation transformer (output 230V AC 3-phase+36V AC 1-phase, such as 1391-T050DT 5kVA model), to ensure UL certification validity;

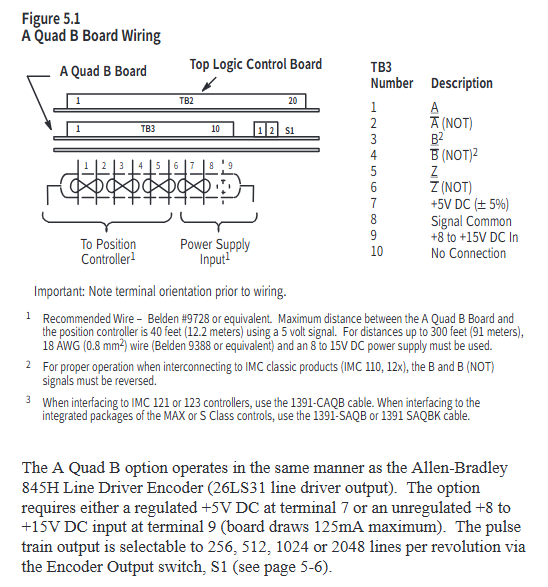

Cable: 1326 CFUxx (resolver line), 1326 CPABxx (motor power line), 1391-CAQB (AQB encoder line) and other specialized shielded cables.

attachment options

Brake power rectifier (1326-MOD-BPS): provides 115V AC input rectification for 90V DC brake;

Planetary gearbox (1326AB-PG series): compatible with different reduction ratios (3:1-100:1), low backlash option (LB) suitable for high-precision scenarios;

Linear Acceleration and Deceleration Module (CR-APG-001): Manually set trapezoidal speed curve, supporting 4 preset speeds.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands