Allen Bradley 1391-DES series digital AC servo drive

Allen Bradley 1391-DES series digital AC servo drive

Basic information of the driver

Product positioning and functionality

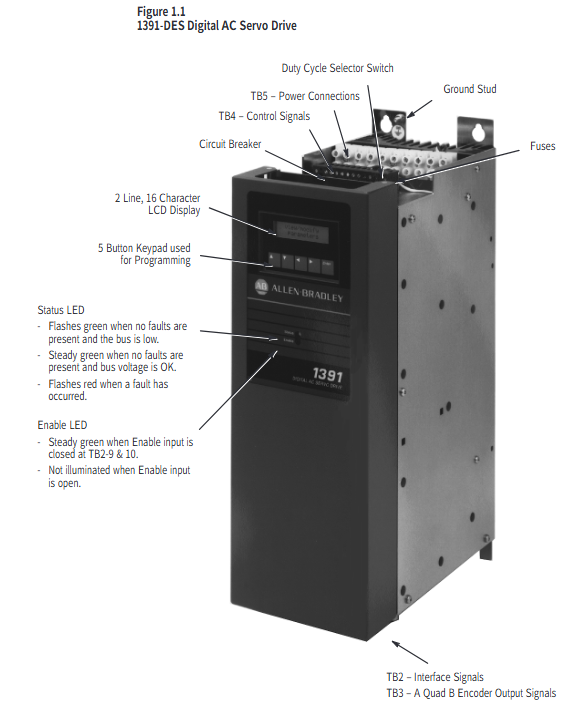

1391-DES is a digital programmable single axis AC servo drive that is compatible with Allen Bradley 1326 series AC servo motors. It is mainly used in closed-loop positioning systems such as machine tools and automation equipment (such as IMC S-class and MAX controllers), and supports speed and torque control modes.

Core advantage: It can enable the 1326 motor to exceed the rated speed by 33% -50%, improving equipment accuracy and production efficiency; Equipped with encoder output (AQB), providing position feedback signals of 256/512/1024/2048 lines per revolution, compatible with positioning controllers.

Model and Key Parameters

Model classification: Divided by continuous current, it is 1391-DES15 (15A), 1391-DES22 (22.5A), and 1391-DES45 (45A), all of which have the same physical dimensions but different electrical parameters.

Core electrical parameters: rated DC bus voltage of 300V DC, peak current twice the continuous current (such as DES45 peak 90A), modulation frequency of 2500Hz ± 10%, speed regulation accuracy of 0-0.05% (under 95% load variation), operating temperature of 0-60 ° C, no need to reduce capacity at altitude ≤ 1000 meters.

Standard configuration and optional features

Standard functions: Input transient voltage protection, built-in circuit breaker, DC bus shunt regulator (dissipating regenerative energy), 2-row LCD display and programming panel, torque feedforward differential input, microprocessor control board (easy to disassemble and troubleshoot).

Optional functions: Contactor auxiliary switch (for motor braking control or status indication), external shunt resistor (suitable for high regenerative energy scenarios, such as optional 386W external resistor for 22.5A drivers), speed/current monitoring output, anti backlash control, linear acceleration/deceleration module (CR-APG-001, supports 4 preset speeds).

Working principle

Core Circuit and Energy Processing

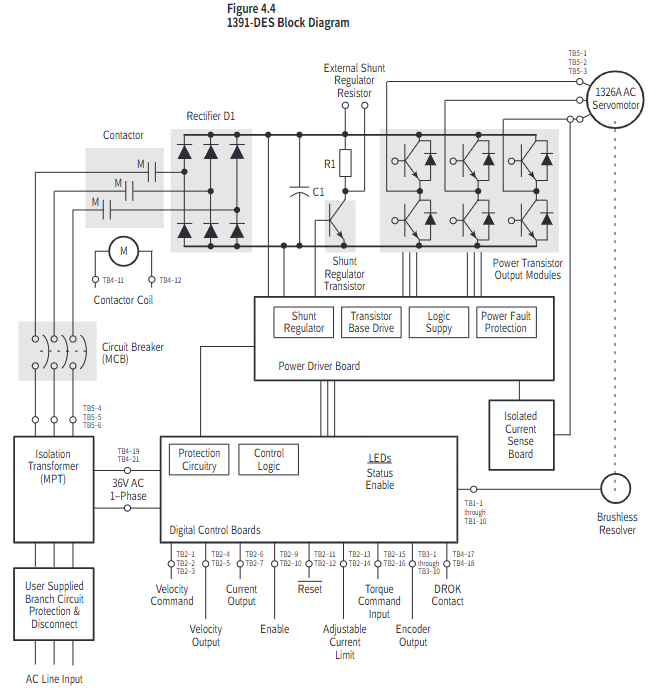

Power Conversion: Convert 3-phase 50/60Hz AC power into 300V DC bus voltage through a rectifier bridge, and then output variable voltage AC power through a PWM inverter to control motor speed and torque.

Regenerative braking: The regenerative energy generated during motor deceleration will increase the DC bus voltage. When the shunt regulator detects that the voltage exceeds the threshold (386.4V DC), it triggers the chopper transistor to conduct, converting the energy into thermal energy through the braking resistor to avoid bus overvoltage tripping (overvoltage protection threshold 405V DC).

control logic

Closed loop control: By using a motor resolver (rotary transformer) to provide feedback on the rotor position, combined with speed/torque commands, and adjusting through current and speed loops, precise control is achieved; The current loop adopts analog control, and the speed command supports ± 10V DC analog input.

Start stop mode: includes three modes: dynamic braking (bus discharge braking when the contactor is disconnected), regenerative braking (reverse torque braking when the enable signal is disconnected), and free parking (driver disconnection output in case of fault, motor inertia parking).

Installation and wiring

Installation requirements

Environment: It needs to be installed in a closed cabinet, and ventilation should be filtered/cooled to avoid oil mist, dust, and corrosive gases; Vertical installation, distance between single driver and motor ≤ 3m, distance between main driver and frequency converter ≤ 3m when multiple drivers, distance between sub drivers and main drivers ≤ 1.5m, equipment spacing ≥ 304.8mm (to ensure heat dissipation).

Grounding: The driver housing needs to be reliably grounded, and signal grounding (such as resolver, control signal) should use a "star grounding" to avoid introducing noise into the grounding loop.

Wiring specifications

Power wiring: The motor power lines (TB5-1~3) and input power lines (TB5-4~6) need to be twisted pair, separately threaded through pipes, and the wire diameter should refer to the manual (such as 8AWG/6mm ² for DES45); The external shunt resistors (TB5-8~10) need to be matched according to the model (for example, a 45A driver requires an external 5 Ω resistor).

Signal wiring: Control signals such as speed command (TB2-1~2), enable signal (TB2-9~10), reset signal (TB2-11), etc. require 18AWG twisted pair cable with a distance of ≥ 304.8mm from the power line; resolver wiring (TB1-1~10) requires shielded wire with the shielding layer grounded at one end.

Switch and jumper settings

Split regulator duty cycle switch (SW1): adjusts the overheat protection threshold of the braking resistor, and different drivers correspond to different gears (such as setting it to "F" gear when DES22 is equipped with an external resistor).

AQB encoder output switch (S1): Select the number of output lines (256/512/1024/2048), which should match the parameters of the positioning controller (such as halving the number of lines for IMC classic controllers).

Programming and Debugging

Parameter hierarchy and operation

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands